Guiding device of multideck table

A technology of guiding device and guiding plate, which is applied in the field of guiding device of multi-layer shaking table, can solve the problems that single-layer shaking table occupies a large area, has not been solved well, affects the production index of the enterprise, and achieves the saving of plant infrastructure investment , simple structure, and the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

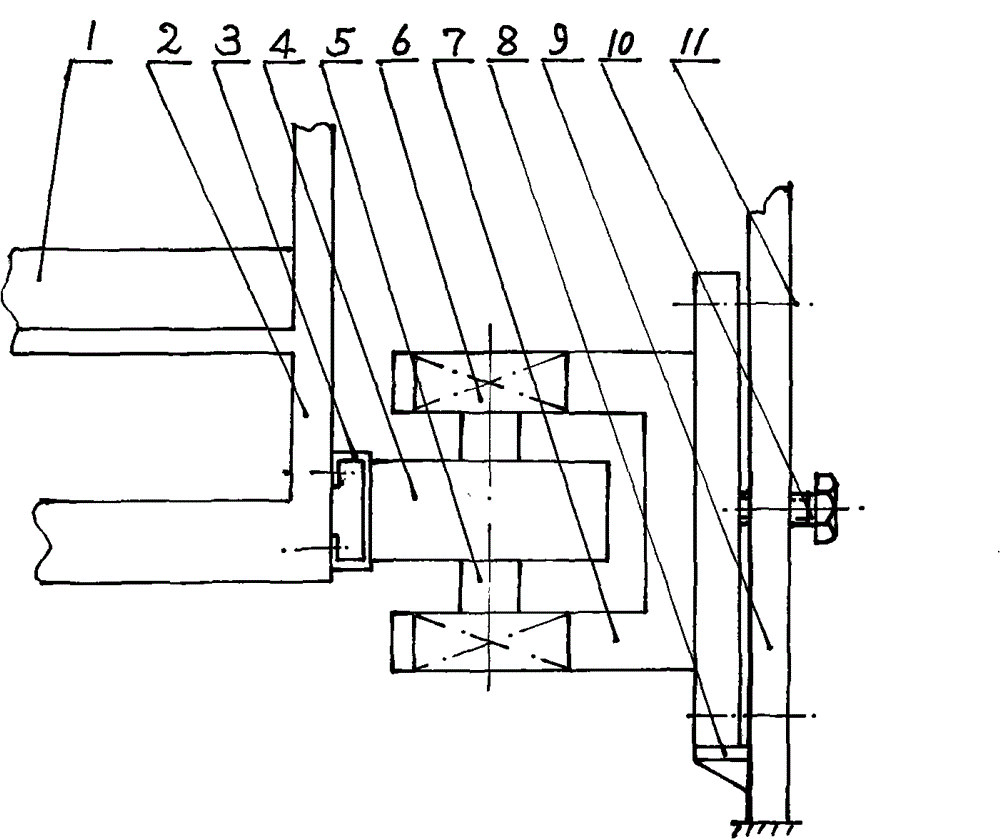

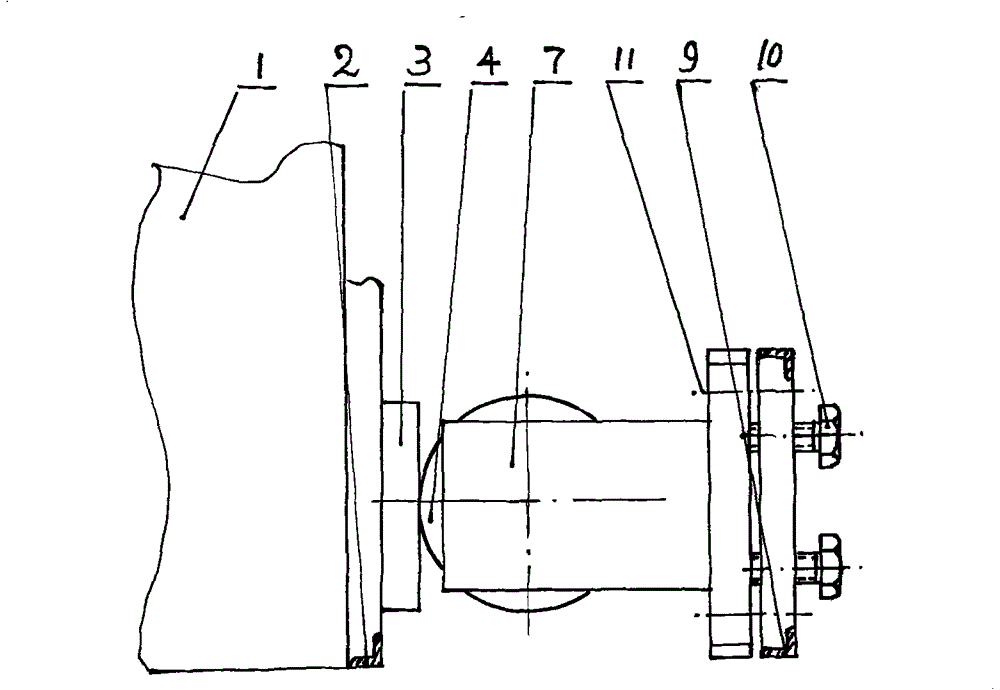

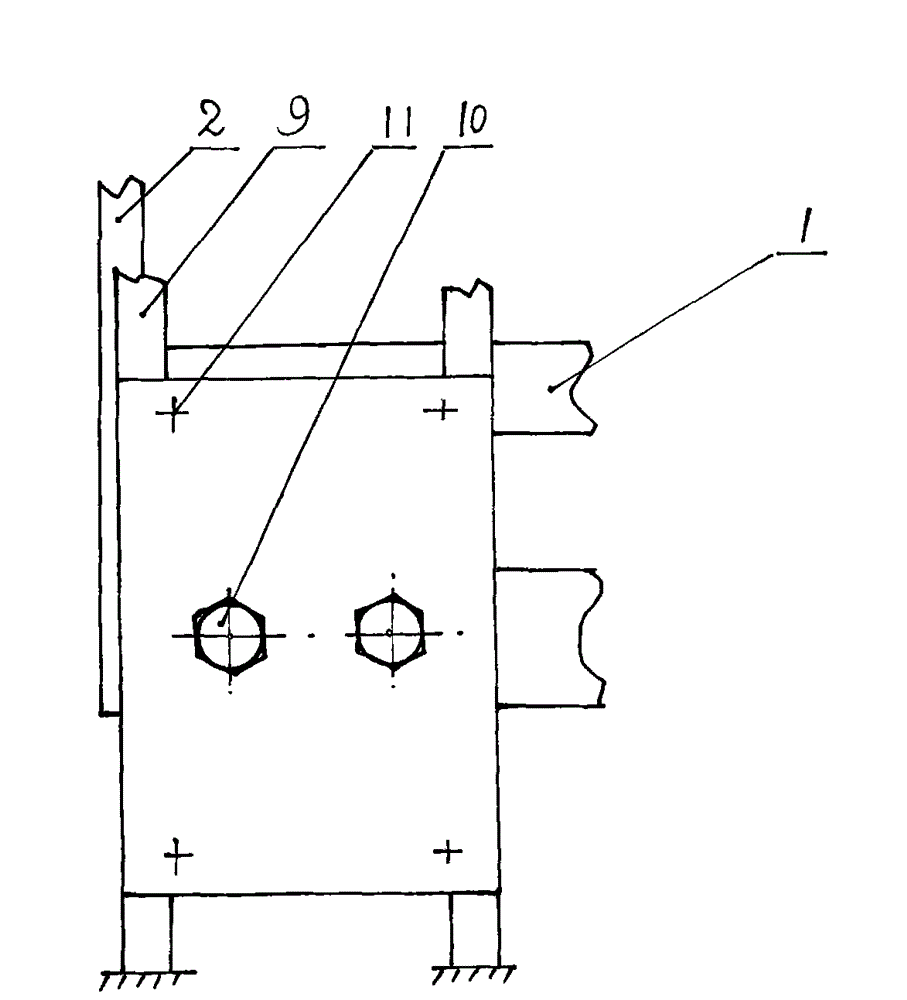

[0021] Such as Figure 1-3 Shown, hanger 2, bed surface 1 are consistent with existing multi-layer shaking table, and the number of layers is 3-5 layers, and the facilities such as slope adjustment, water transfer, ore feeding of multi-layer shaking table also do not change. Four grooved friction guide plates 3 are only welded or bolted on the two sides of the hanger, and the friction surfaces of the guide plates are guaranteed to be parallel to the straight line of the shaking table and perpendicular to the ground. Running wheel 4, wheel shaft 5 and wheel frame 7 are all made of steel, and two bearings 6 are commercially available products of standard, can use general ball bearing, or marble bearing. Ordinary sliding bearings can also be used.

[0022] The basic shape of the wheel frame is groove-shaped, and the opening faces the friction guide plate. Each of the four corners of the frame base plate has a mounting hole, which is fixed on the fixed bracket 9 with connecting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com