Opposite type explosion welding device and method of metal composite materials

A metal composite material and explosive welding technology, which is applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of low energy utilization rate, welding failure, large investment, etc., to eliminate adverse effects and reduce Effects of processing costs and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

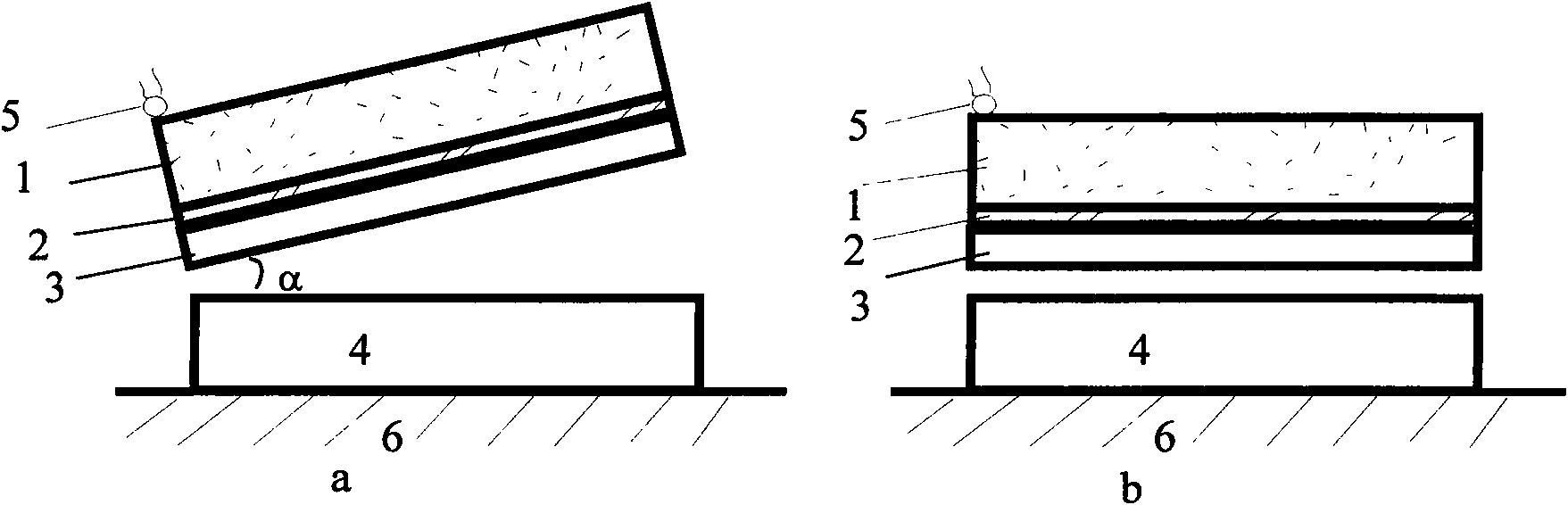

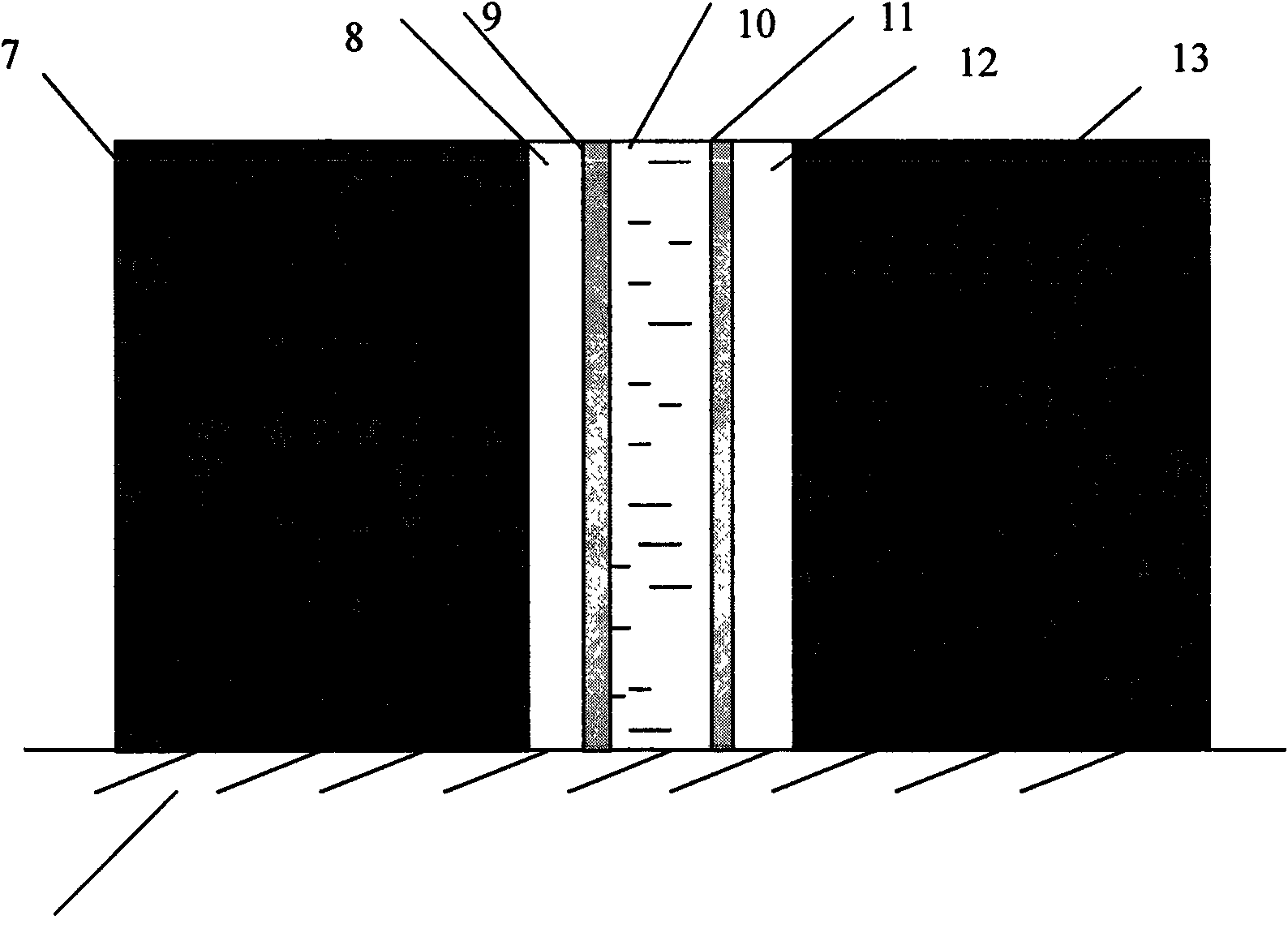

[0020] Control attached figure 2 , Explosive two pairs of stainless steel-steel composite panels, the specifications of 1500×2000×(6+20), if the parallel explosive welding method is used, about 120 kilograms of explosives are required, and two explosive operations are required; and the opposite explosive welding method of the present invention is adopted It only needs to be done once, consumes less than 40 kilograms of explosives, and the blasting noise is small.

Embodiment 2

[0022] Control attached figure 2 , Explosive two pairs of tool steel-steel clad plates, with a specification of 800×1500×(6+30). If the parallel explosive welding method is used, 50 kg of explosive is required, and two explosive operations are required; while the opposite explosive welding method of the present invention is used It only needs to be done once, consumes 16 kg of explosives, and the blasting noise is small.

Embodiment 3

[0024] Control attached figure 2 , The explosion of two pairs of copper-steel composite panels, the specifications of 500×6000×(8+28), if the parallel explosive welding method is adopted, 130 kilograms of explosives are required, and two explosive operations are required; while the opposite explosive welding method of the present invention only It needs to be done once, consumes 43 kg of explosives, and the blasting noise is small.

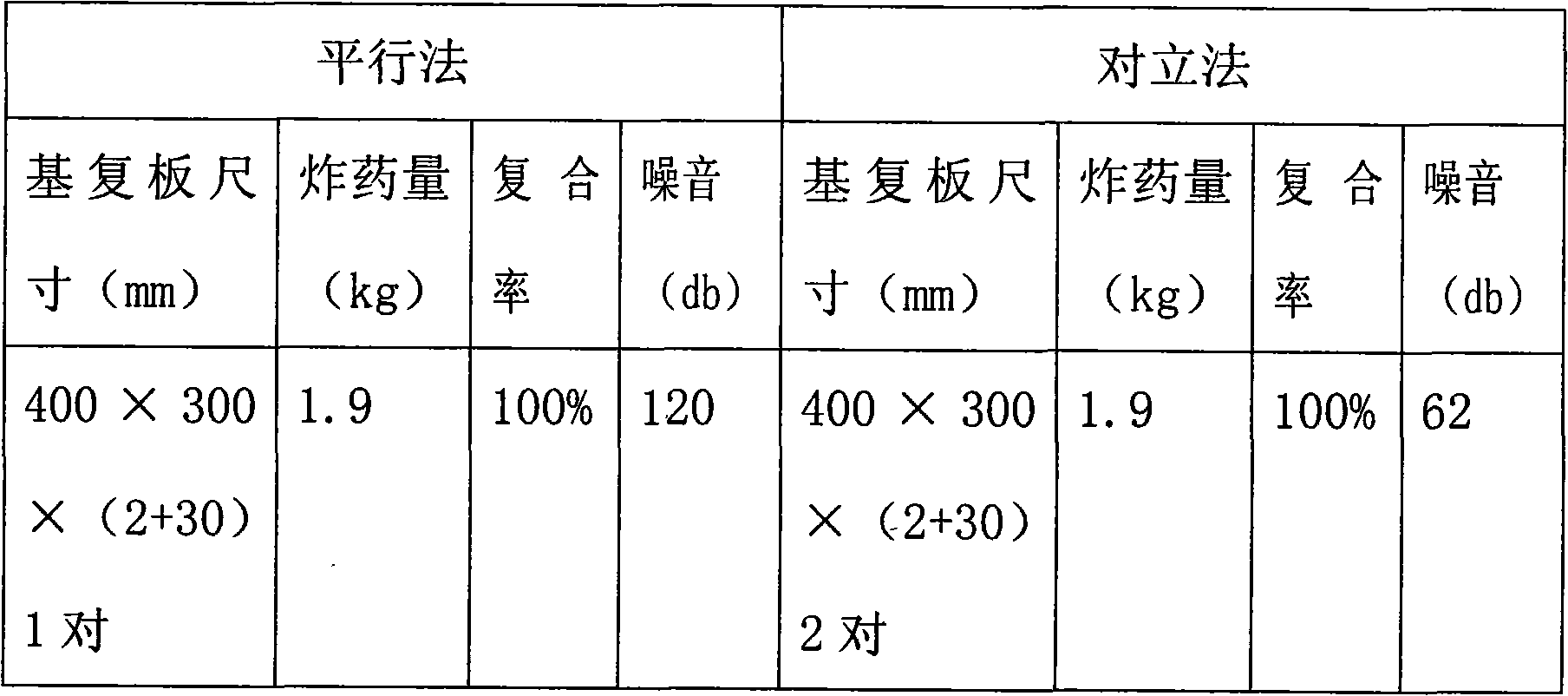

[0025] The following is a comparison between the parallel method and the experimental data after testing the legislative explosive welding process, as shown in Table 1, where the noise is the data measured 200 meters from the explosion point.

[0026] Table 1

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com