Revolving frictional generator

A technology of rotating friction and generator, applied in the direction of friction generator, etc., can solve the problems of inconvenience of portability, price dependence, high cost, and achieve the effect of simple structure, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention provides a rotating friction generator, and the present invention will be further described below through the description of the drawings and specific embodiments.

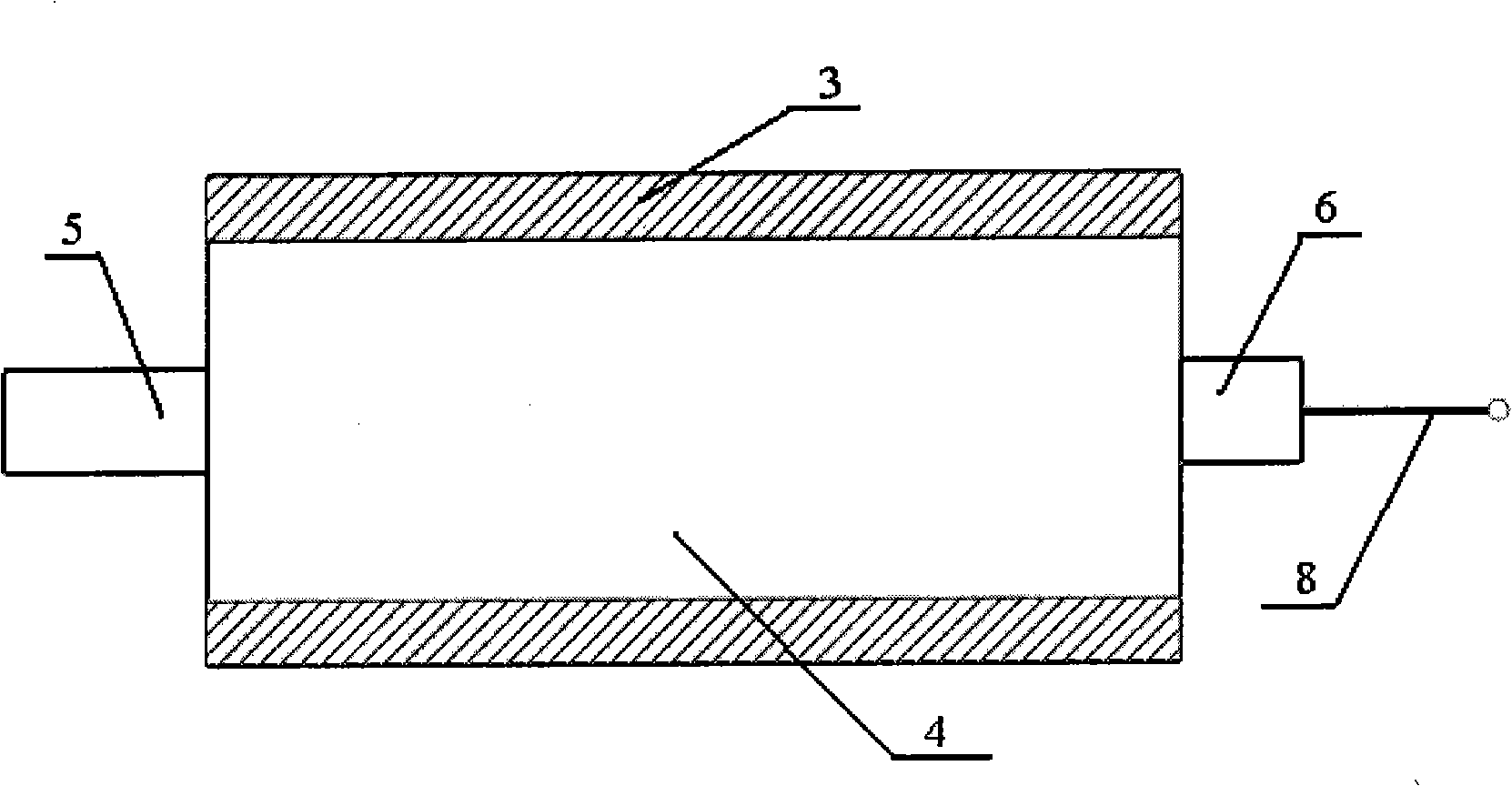

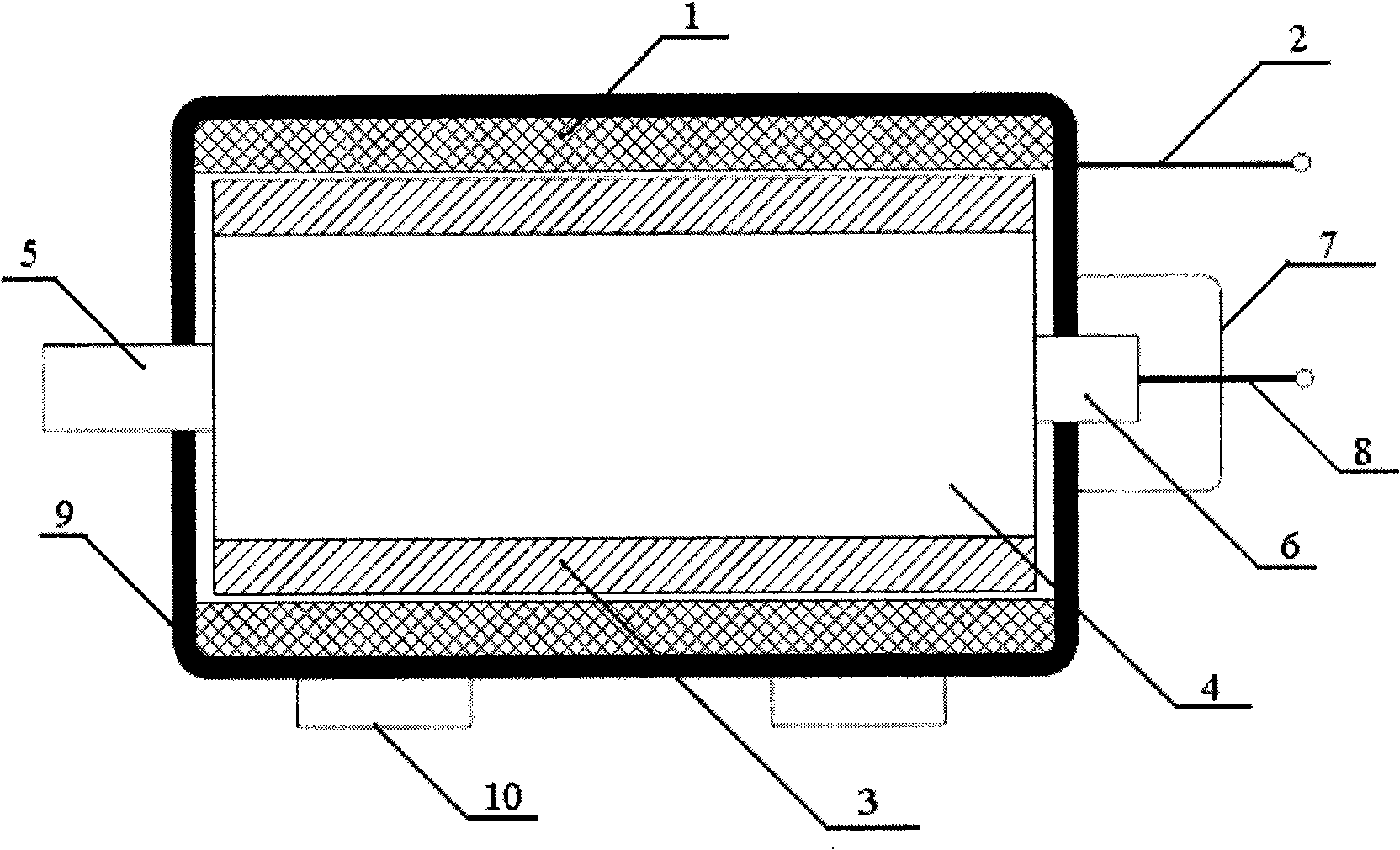

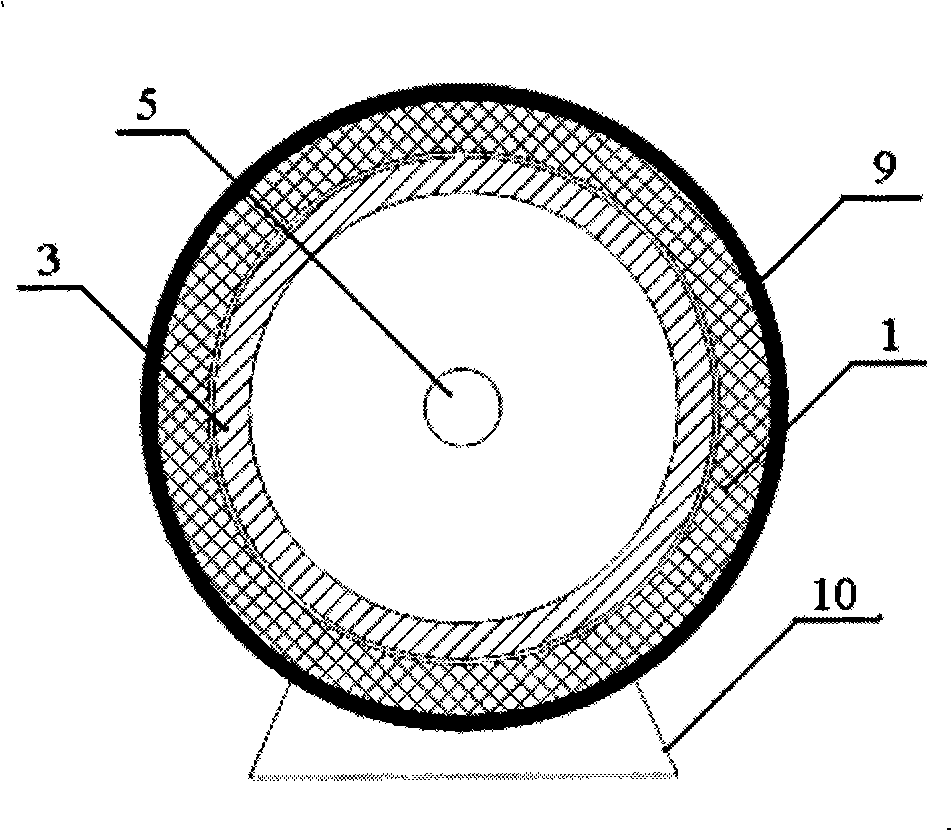

[0013] figure 1 is an axial sectional view of the main rotor structure of the rotating friction generator; figure 2 is an axial sectional view of the rotating friction generator. The stator is composed of a stator friction material layer 1 evenly fixed and distributed on the inner wall of the cylindrical shell 9 and a stator output terminal 2 fixed on the outer wall of the shell 9, wherein the stator friction material layer 1 is made of rubber and has a thickness of 15mm; The structure of the rotor is as follows: the rotor friction material layer 3 is evenly fixed and distributed on the outer wall of the cylindrical rotor shaft tube 4, and the drive shaft 5 and the collector shaft 6 are respectively fixedly installed on the axis lines of the two bottom surfaces of the rotor shaft tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com