Decorative sheet

A decorative sheet and polyester film technology, which is applied in decorative arts, decorative structures, and techniques for producing decorative surface effects, etc., can solve problems such as decorative sheet cracking, and achieve good adhesion and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Manufacture of decorative sheets

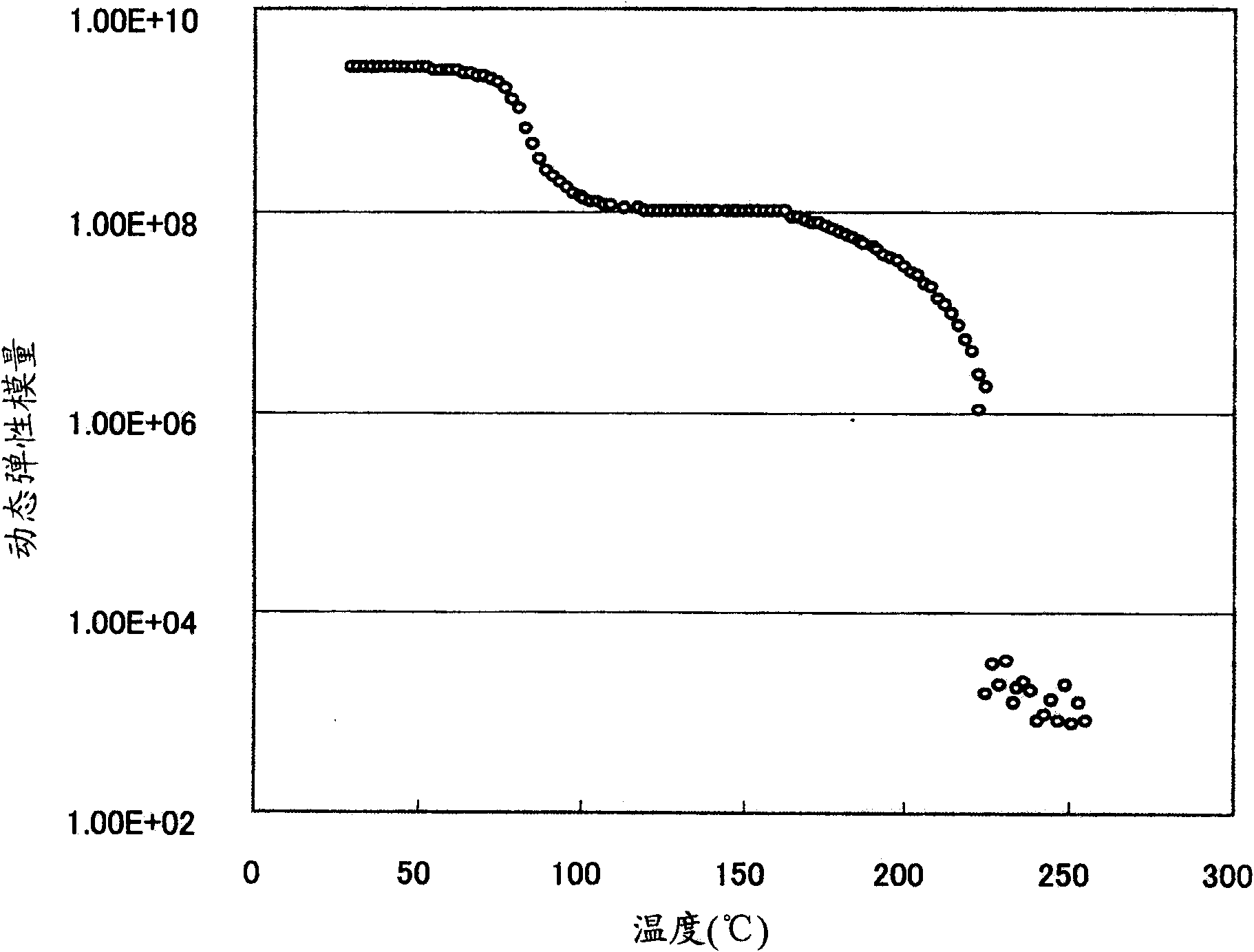

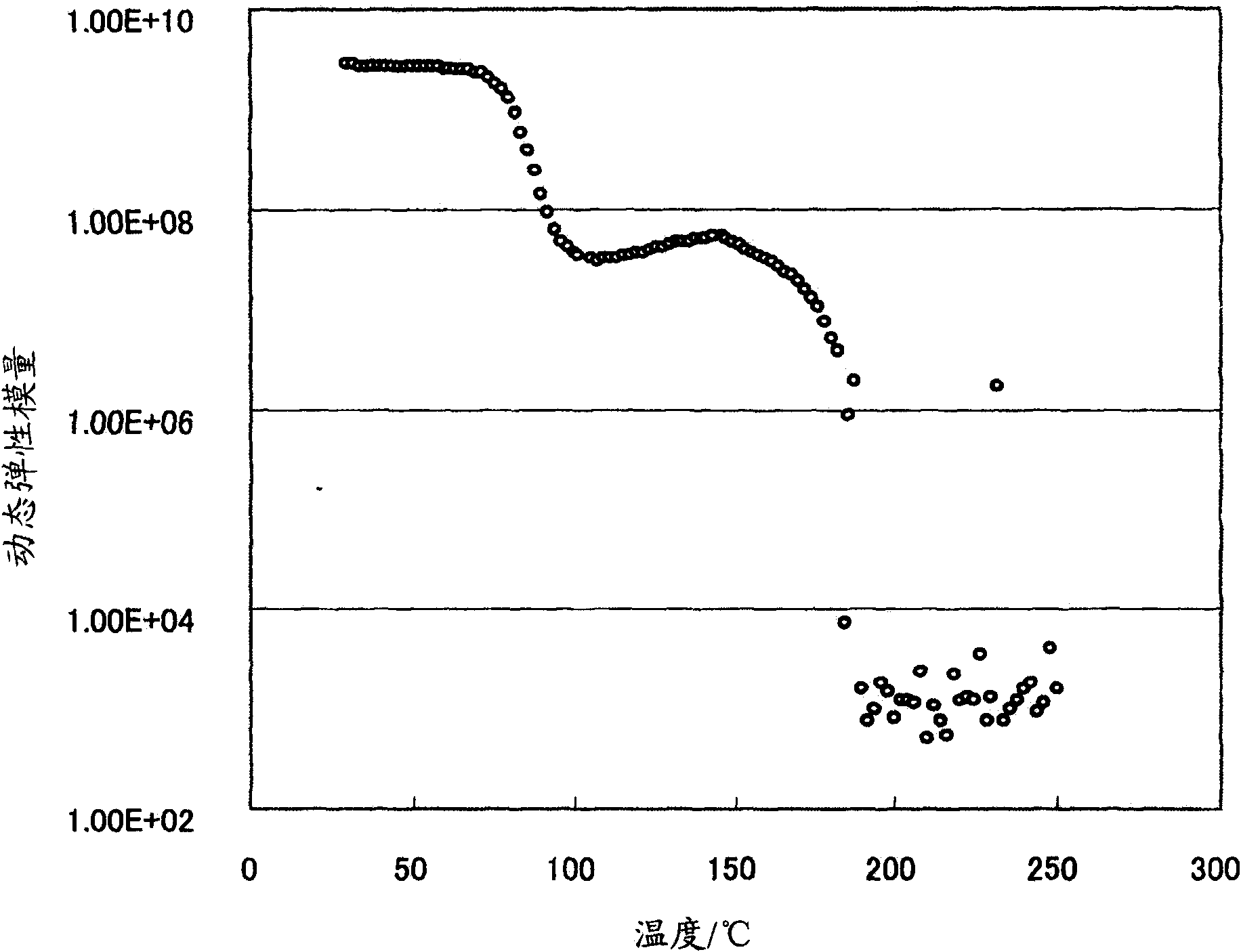

[0065] In the thickness of 75μm, and has figure 2 Use the following coating solution on the biaxially stretched PET film with the dynamic elastic modulus shown in the coating amount of 4g / m 2 Implement gravure printing to form a peeling layer. The coating liquid uses acrylic resin as a binder resin and silicone resin as a release material; acrylic printing ink is used in a coating amount of 8 g / m 2 Gravure prints the wood grain pattern, forming the pattern layer. Then, an acrylic resin-based coating solution was applied to a thickness of 4 μm to form a thermally adhesive resin layer, thereby obtaining a decorative sheet.

[0066] (2) Manufacture of decorative moldings

[0067] The decorative sheet obtained in the above (1) was heated with a heating plate temperature of 150° C. to form it according to the inner shape of the injection molding mold and closely bond with the inner surface of the mold. The mold used has a shape wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com