Self-propelled corn harvester

A harvester and self-propelled technology, which is applied in the direction of harvesters, cutters, crop processors, etc., can solve the problems of high power consumption, affecting farming, and easy failures, etc., to achieve low power consumption, not easy to break down, easily damaged effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

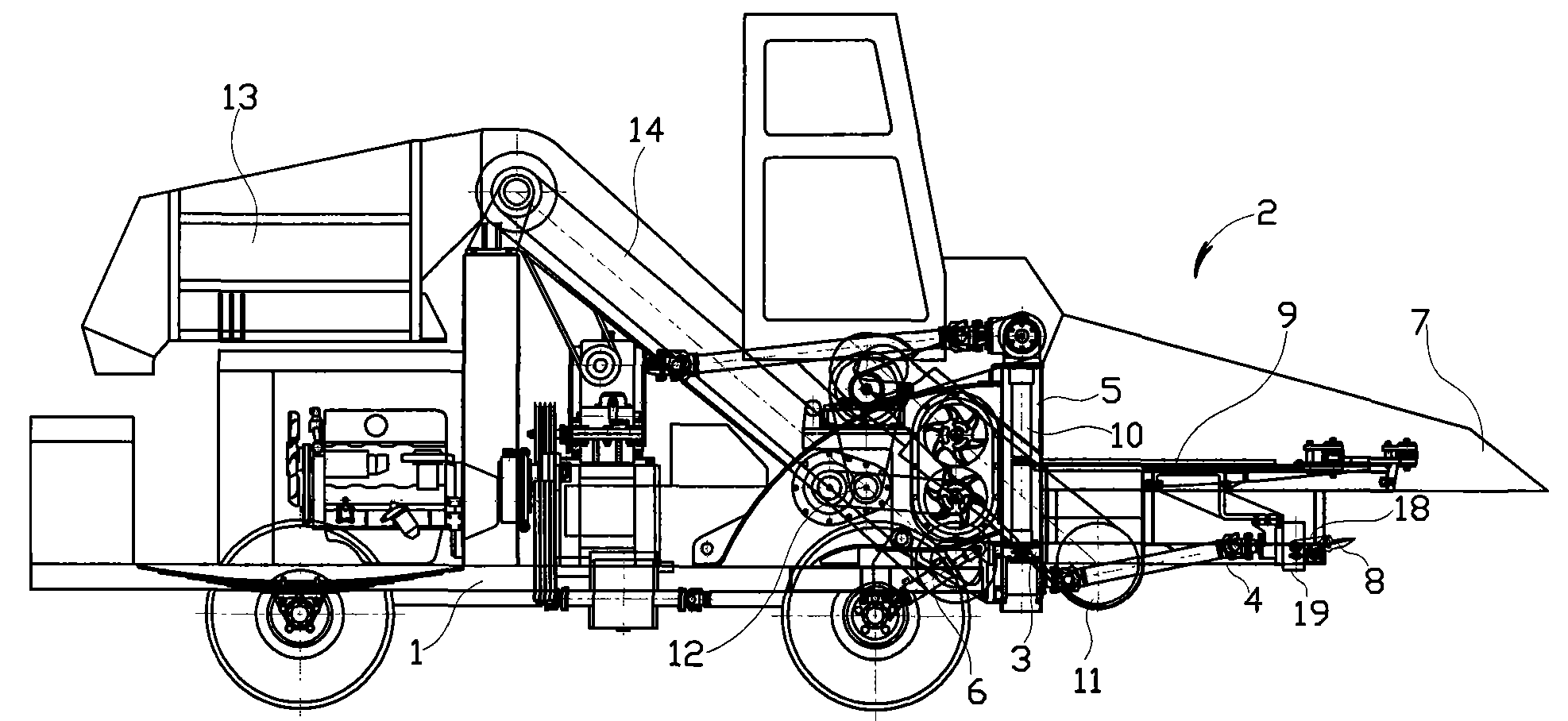

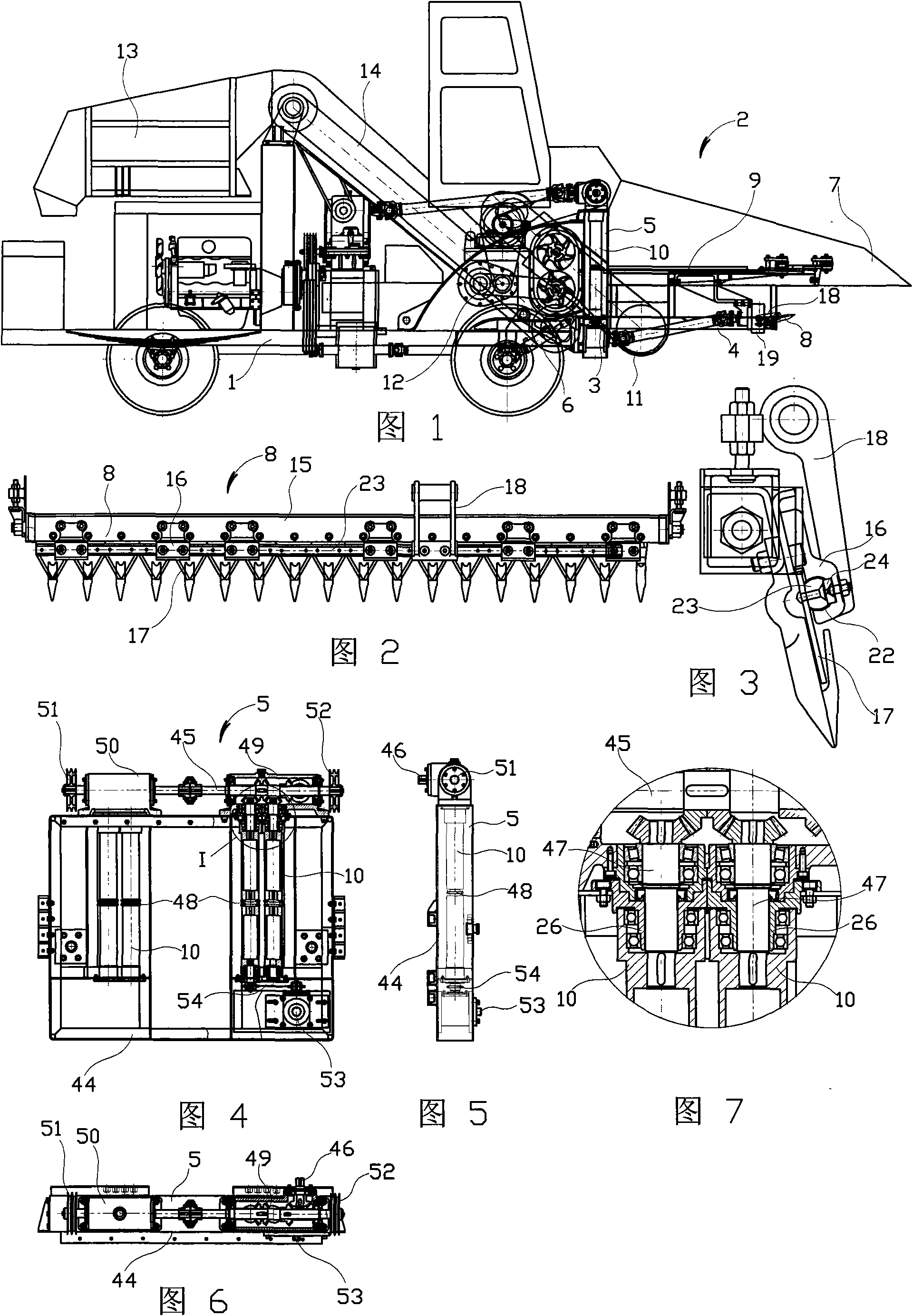

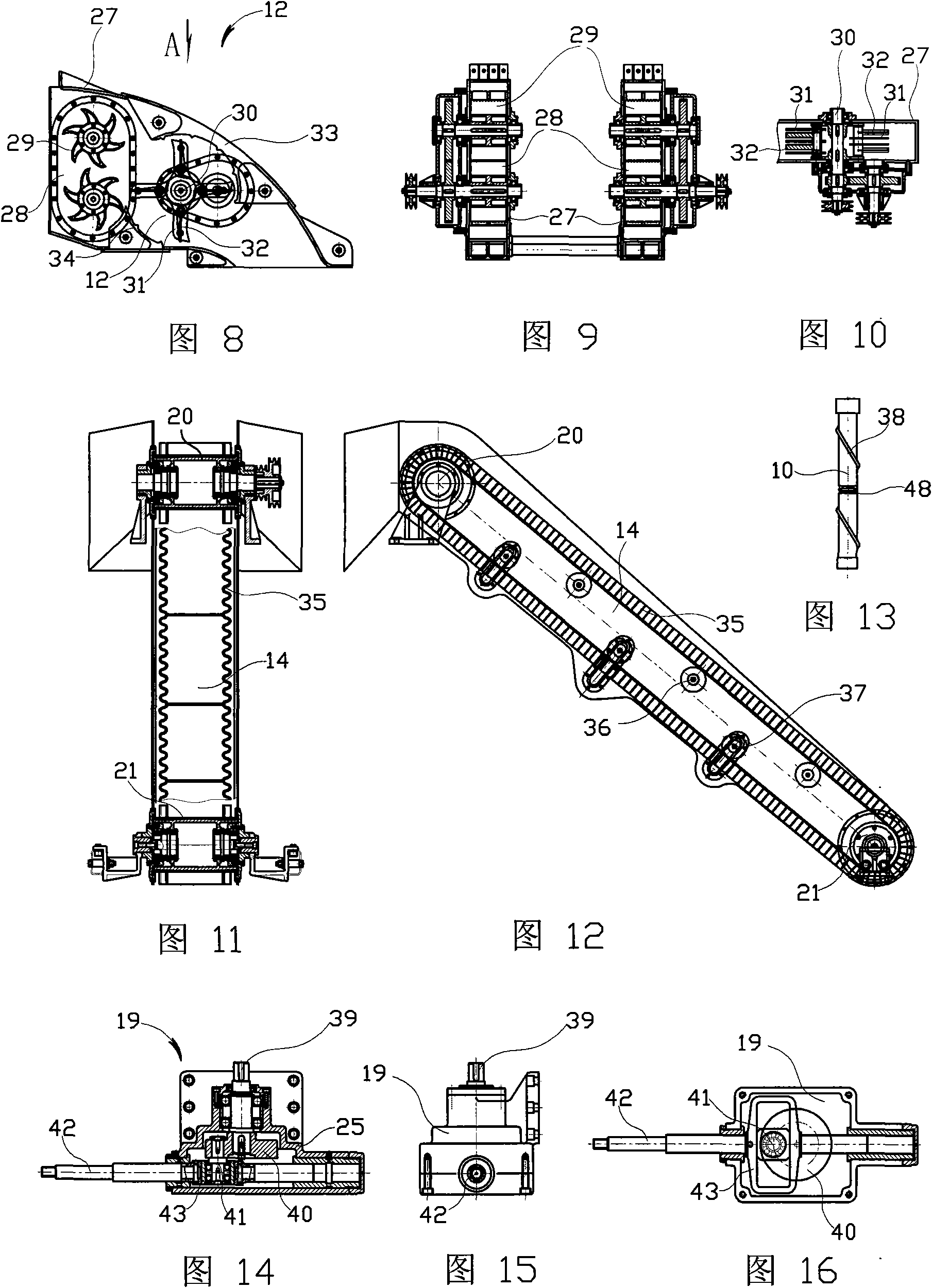

[0033] In Fig. 1~Fig. 16, the self-propelled corn harvester has motor vehicle 1, and the front part of motor vehicle frame is hinged with header 2, header has L-shaped frame 3, and L-shaped frame has horizontal frame 4 and vertical frame 5, There is a hydraulic cylinder 6 connected between the vertical frame of the header and the vehicle frame, the front end of the horizontal frame of the header has a grain lifter 7, a cutting knife 8 is placed under the grain lifter, and a clamping conveyor chain 9 is arranged behind the cutter. There is vertical ear picking roller 10 on the conveyor chain rear, vertical frame, corn ear groove 11 is arranged on the front and lower part of ear picking roller, straw crusher 12 is connected with the rear of ear picking roller, and ear box 13 is arranged at the rear of the vehicle frame, and ear There is a peeling machine (not shown in the figure) above the box, and there is a corn ear conveyor 14 between the middle part of the vehicle frame, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com