Swiveling mechanism and engineering machinery with swiveling mechanism

A slewing mechanism and component technology, which is applied in the directions of earthmoving machines/shovels, cranes, building structures, etc., can solve the problem of increasing the use cost and maintenance cost of the bearing-type slewing mechanism, the low maintainability of the slewing bearing 300, and the bearing-type slewing mechanism. The high manufacturing cost of the slewing mechanism achieves the effect of strong maintainability, simple structure and low slewing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

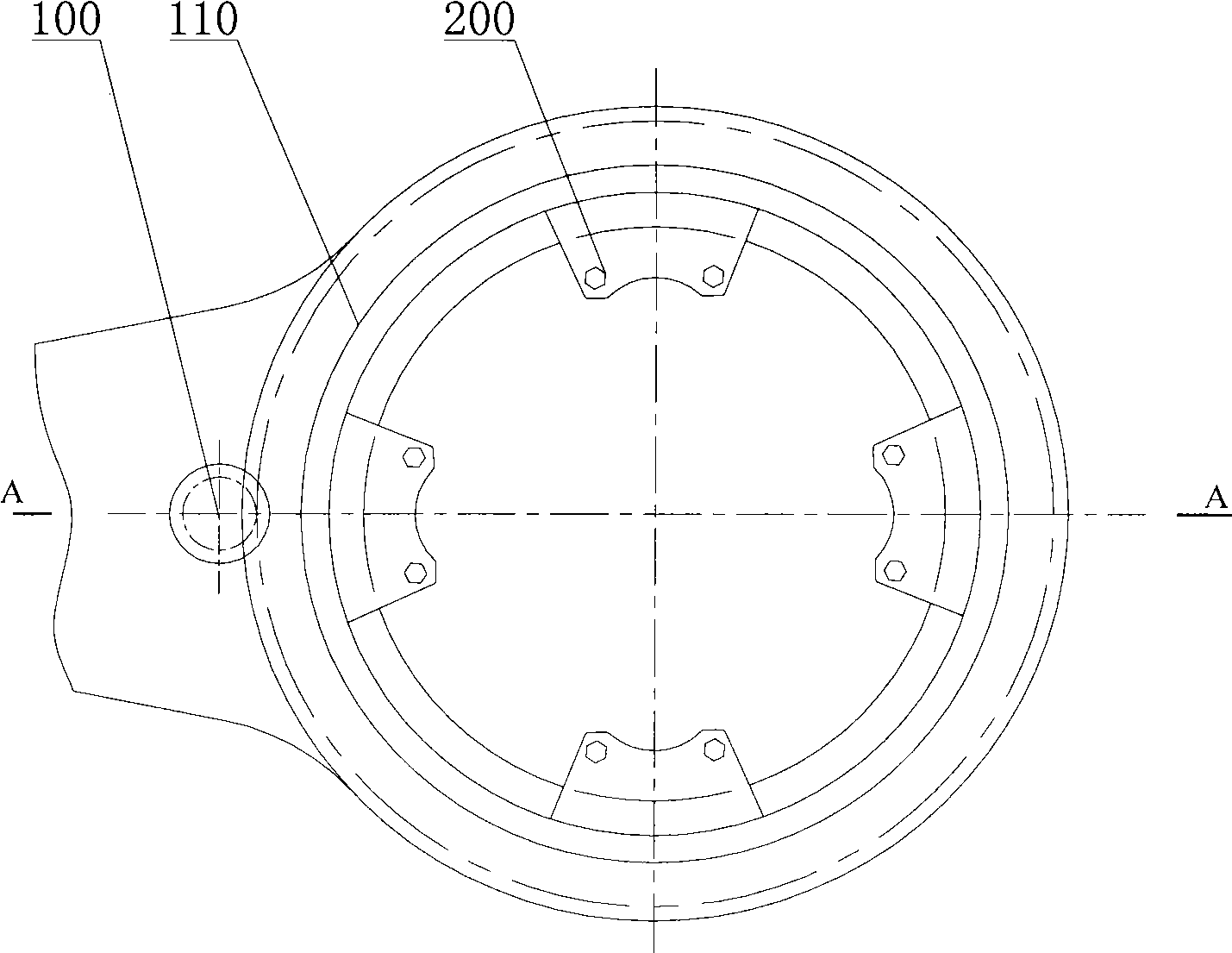

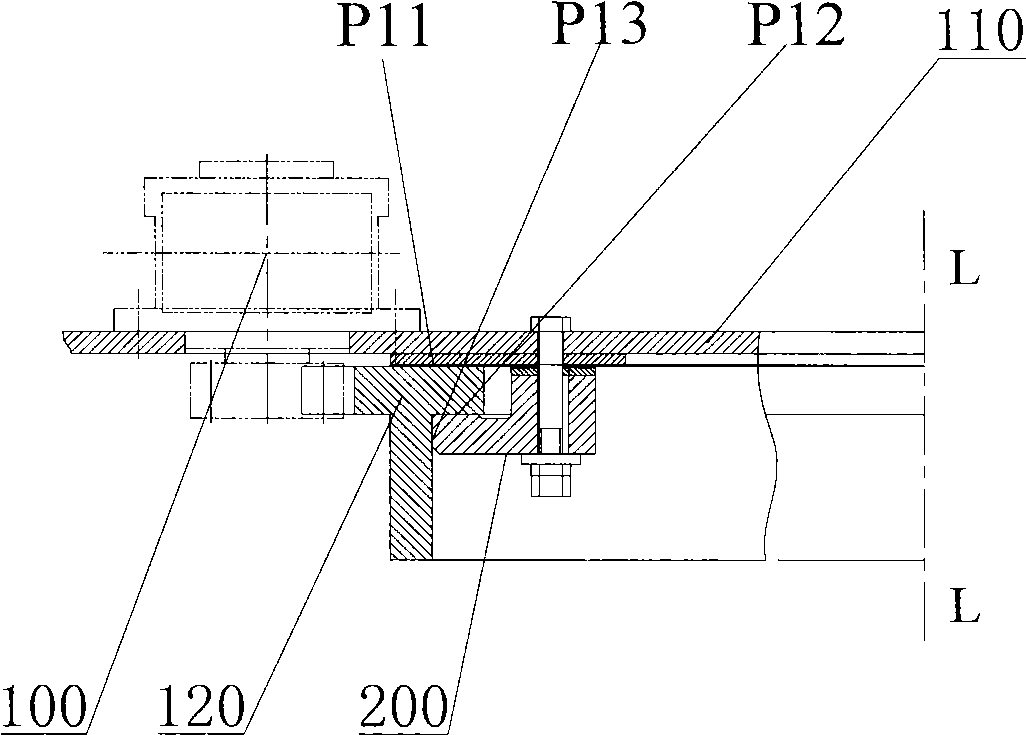

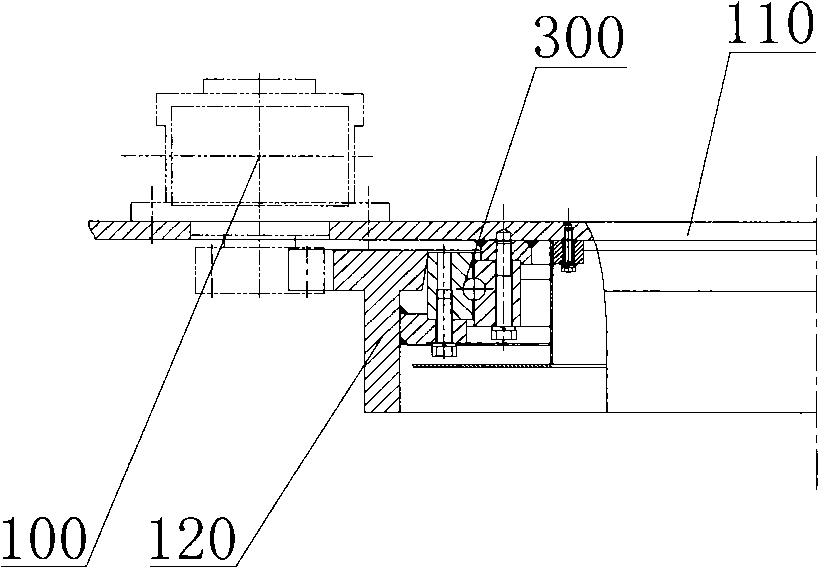

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0045] It should be noted that: in this document, the axial direction is a direction parallel to the axis of rotation of the slewing mechanism; it can be understood that the slewing mechanism provided by the present invention is not limited to horizontal arrangement, but can also be arranged vertically.

[0046] The basic idea of the slewing mechanism provided by the present invention is to convert the appropriate sliding friction structure in the tray-type slewing mechanism into a rolling friction mechanism to reduce the slewing resistance; at the same time, compared with the bearing-type slewing mechanism, it has simple structure and The feature of strong maintainability facilitates the mass production and manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com