Spring-combination-type vibration isolator

A combined type, vibration isolator technology, applied in the direction of low internal friction spring, can solve the problems of difficult adjustment, poor overall vibration isolation effect, etc., to achieve great flexibility and overcome aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

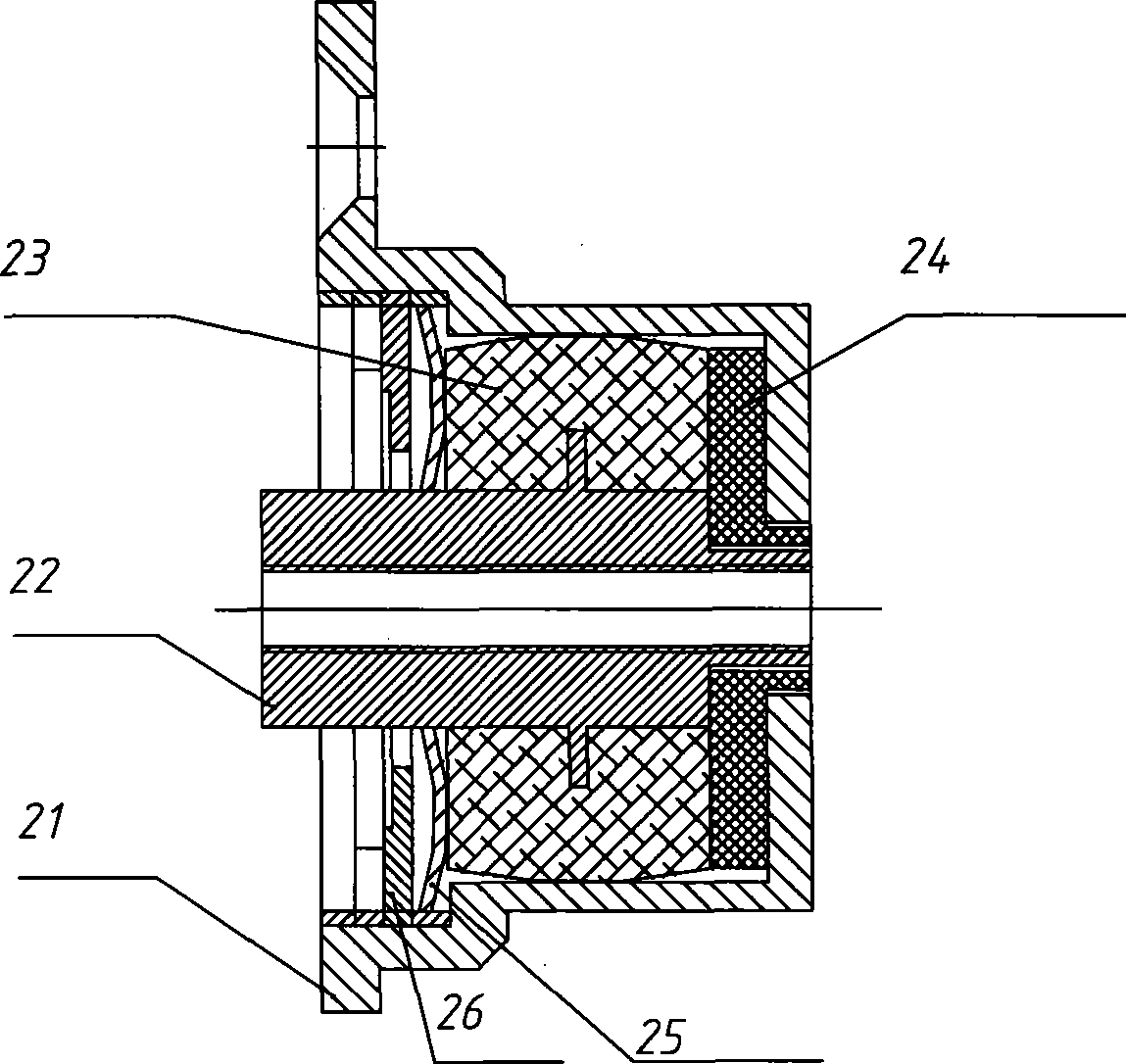

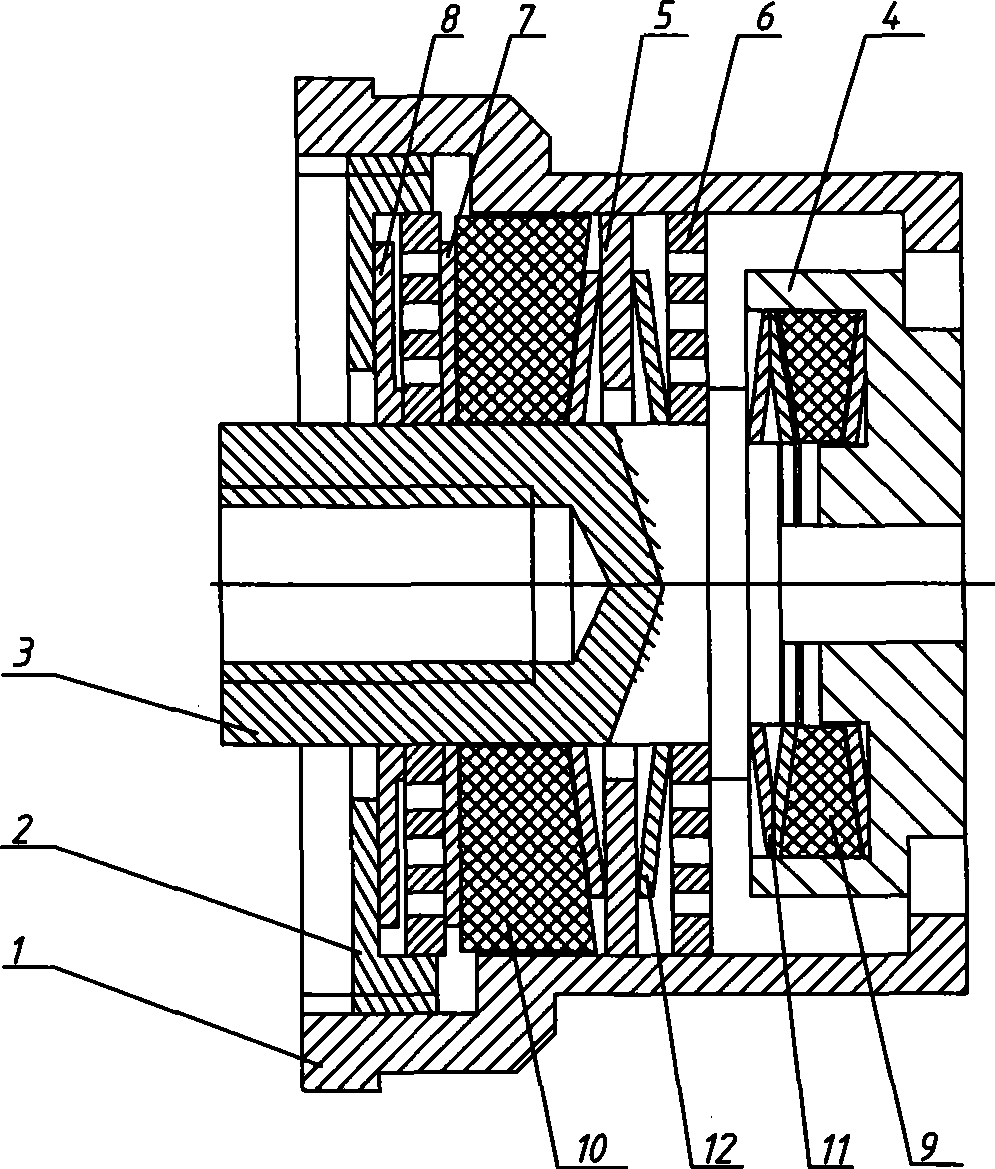

[0030] like figure 2 As shown, the spring combination type vibration isolator of the present invention mainly includes a housing 1 with an inner hole, an adjusting screw sleeve 2, a locking bolt 3, an anti-rotation sleeve 4, an axial stiffness buffer and an axial and horizontal stiffness buffer , wherein the housing 1 has an inner hole, one end of the inner hole is open, an inner thread is arranged in the opening, and the other end has an end face, which is provided with a cross-shaped hole 13 as shown in Figure 4; the anti-rotation sleeve 4 is installed in the inner hole, A semi-closed annular groove is provided in the axial direction of the anti-rotation sleeve 4. The closed side of the anti-rotation sleeve 4 is closely attached to the end face of the inner hole of the casing. On the outer end surface of the closed side of the anti-rotation sleeve 4, long strips are arranged symmetrically up and down. shaped bump 14 Figure 5a , the elongated protrusion 14 is matched with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com