Device for testing underwater brisance of explosive

A technology for severity and explosives, which is applied in the field of devices for testing the dynamism of explosives, and can solve the problems such as the lack of a simple and easy method for the test of the underwater explosive performance of explosives, the interruption of detonation, and the influence of the blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

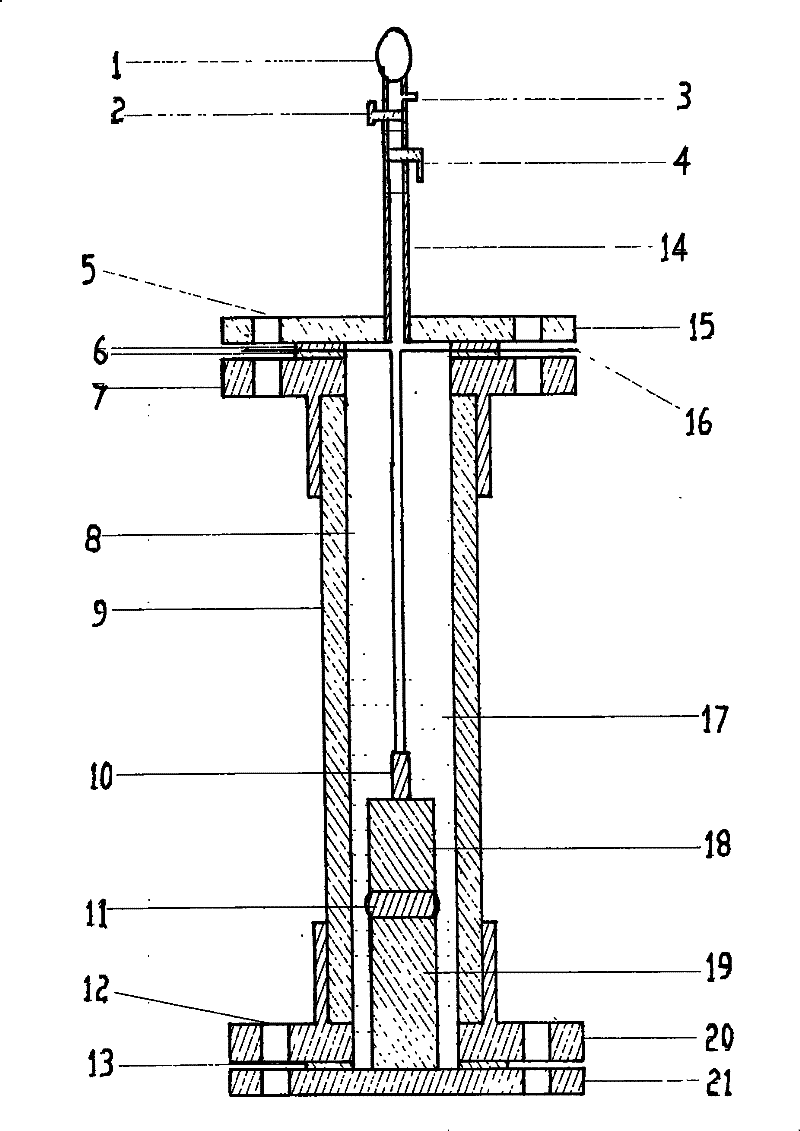

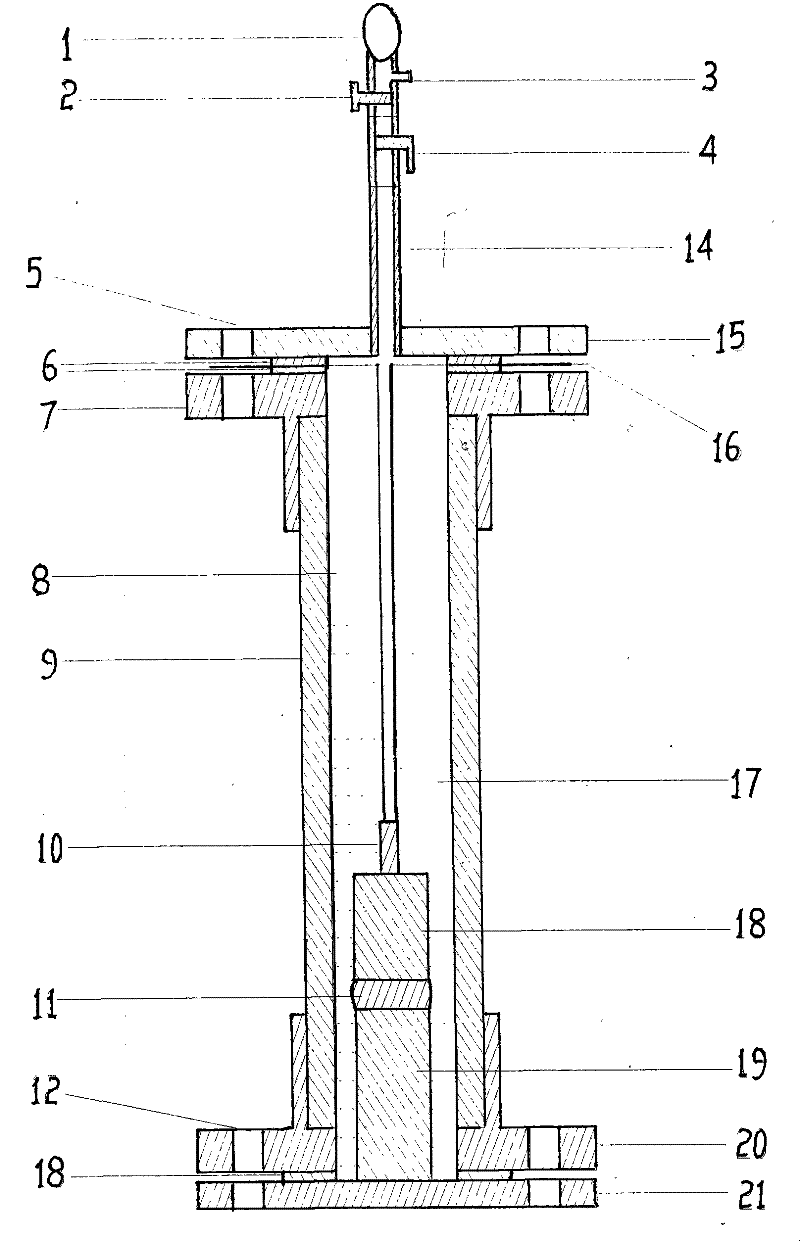

[0013] Embodiment 1, the upper sealing flange 15 of the pipe body of this device is made of steel, and the upper sealing flange 7 of the pipe body, the pipe body 9, and the lower sealing flange 20 of the pipe body are all made of PVC. Made of PVC pipe with compressive strength ≥ 1.0Mpa, between the upper seal of the pipe body, the lower flange 7 and the pipe body 9, and between the pipe body 9 and the upper flange 20 of the lower seal of the pipe body, bonded and sealed with professional glue . Such as figure 1 Put waterproof detonator 10, explosive sample 18, steel sheet 11, lead column 19 as shown; Detonator foot wire 16 is connected with detonating device after being drawn between the gaskets of upper and lower rubber gaskets 6 on the upper seal of the pipe body.

Embodiment 2

[0014] In Embodiment 2, the pipe body 9 of the device, the upper sealing flange 7 on the pipe body, and the upper flange 20 on the lower sealing of the pipe body are all made of steel parts, and the others are the same as in Embodiment 1. Between the lower flange 7 of the upper seal of the pipe body and the pipe body 9, between the pipe body 9 and the upper flange 20 of the lower seal of the pipe body are sealed by welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com