Assembly fixture for voice coil motor

A technology for voice coil motors and assembly jigs, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc. It can solve the problems of difficult assembly of magnetic components, high cost, and time-consuming, and achieve the effect of convenient design work and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

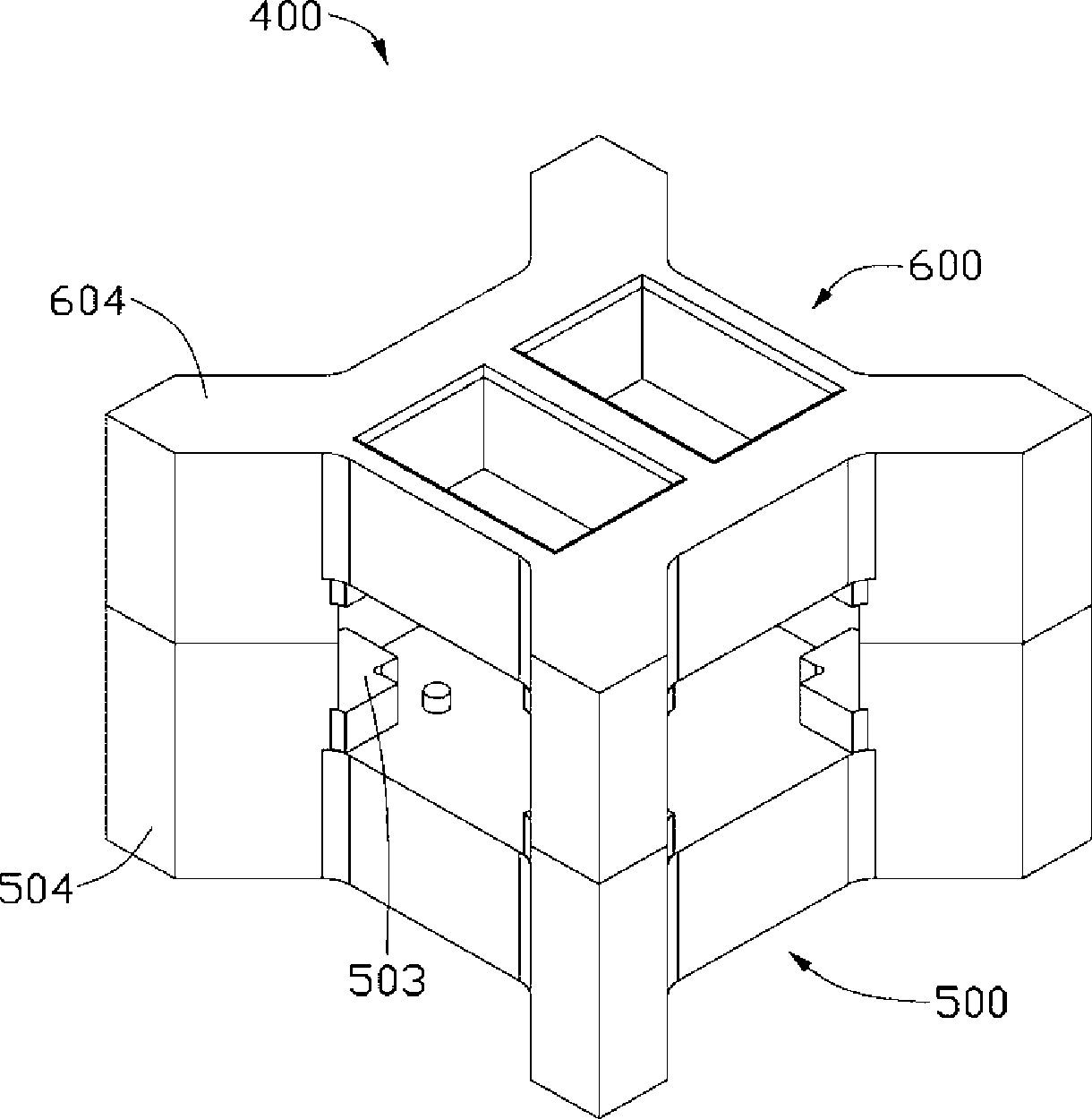

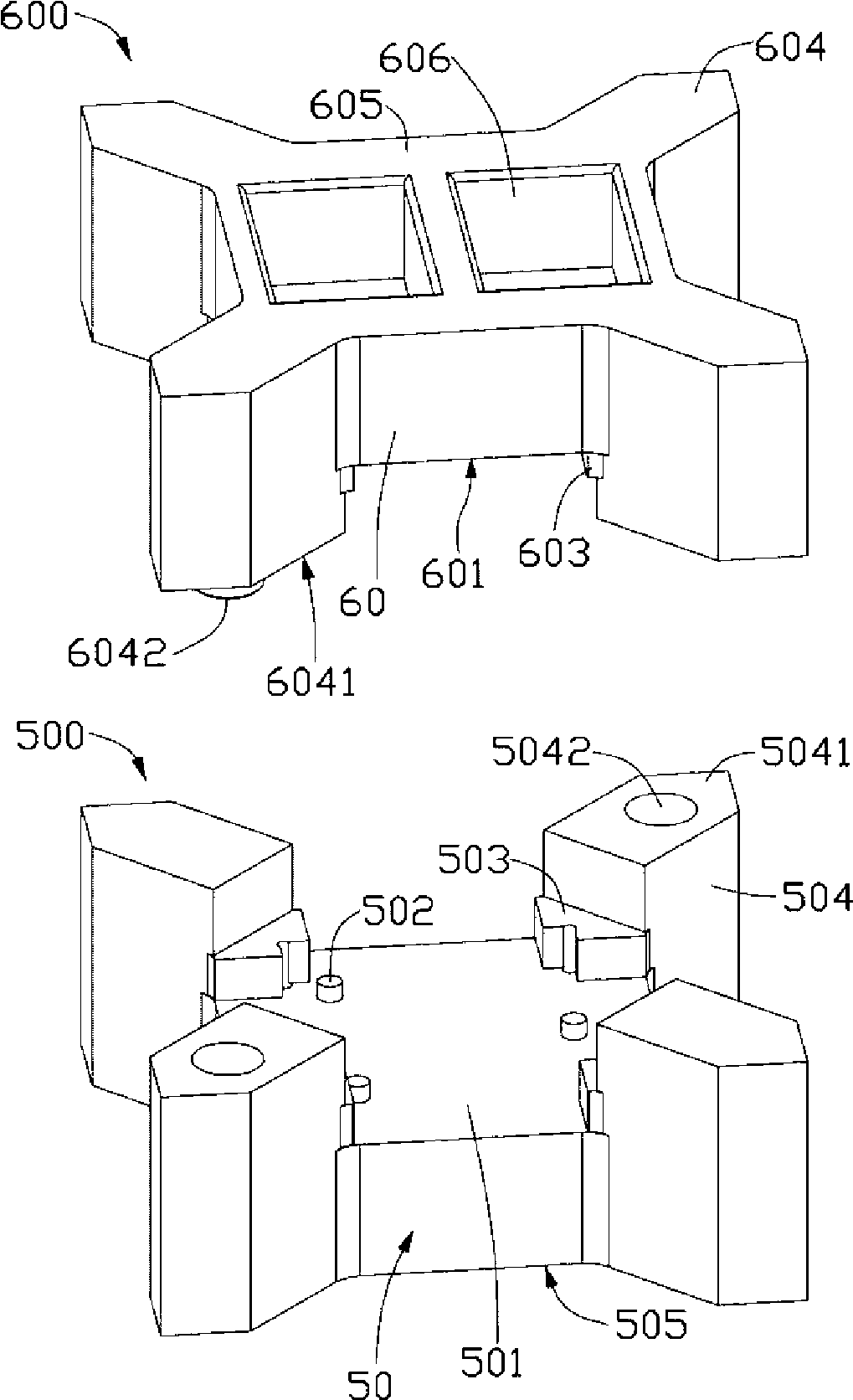

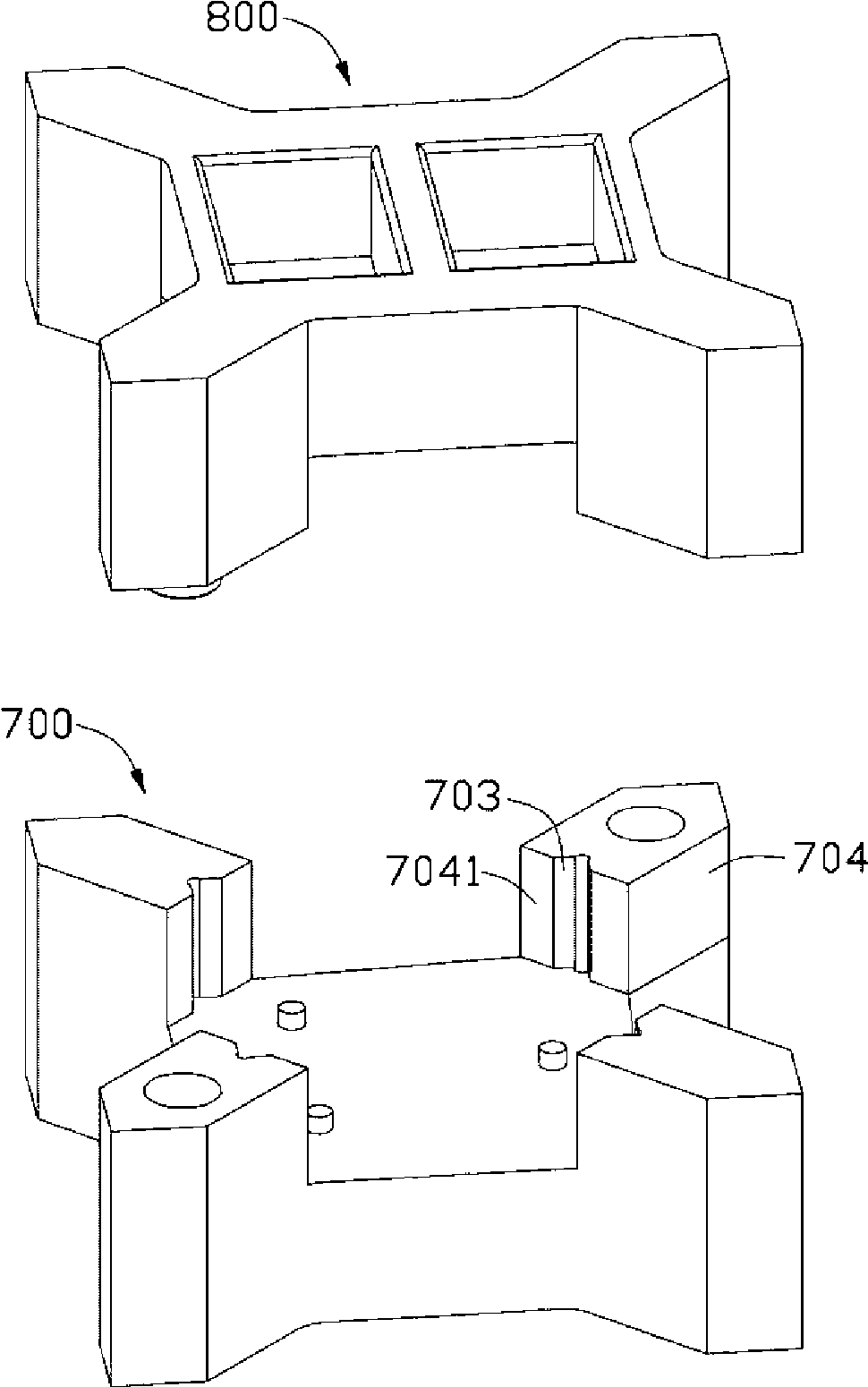

[0011] see figure 1 and figure 2 , the voice coil motor assembly jig 400 provided by the first embodiment of the present invention includes a base 500 and a cover 600 .

[0012] The base 500 includes a cube body 50 , two pairs of base legs 504 diagonally distributed around the body 50 , two pairs of positioning structures 503 , three support columns 502 , and two magnet slots (not shown).

[0013] The body 50 has a surface 501 and another surface 505 opposite to the surface 501 . The three support columns 502 are located on the surface 501 , and the line connecting the three support columns 502 is approximately an equilateral triangle, and the center of the equilateral triangle coincides with the center of the body 50 .

[0014] Each base leg 504 has an end surface 5041 , and a pair of base legs 504 has a positioning hole 5042 respectively, and the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com