Centrifuge and centrifuging method

A centrifugal separator and centrifugal separation technology, applied in centrifuges, centrifuges with rotating drums, analyzing materials, etc., can solve the problems of destroying stem cells, increasing the risk of contaminating stem cells, and requiring a lot of time for cleaning, and achieving accurate classification. and collection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

best mode

[0064] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

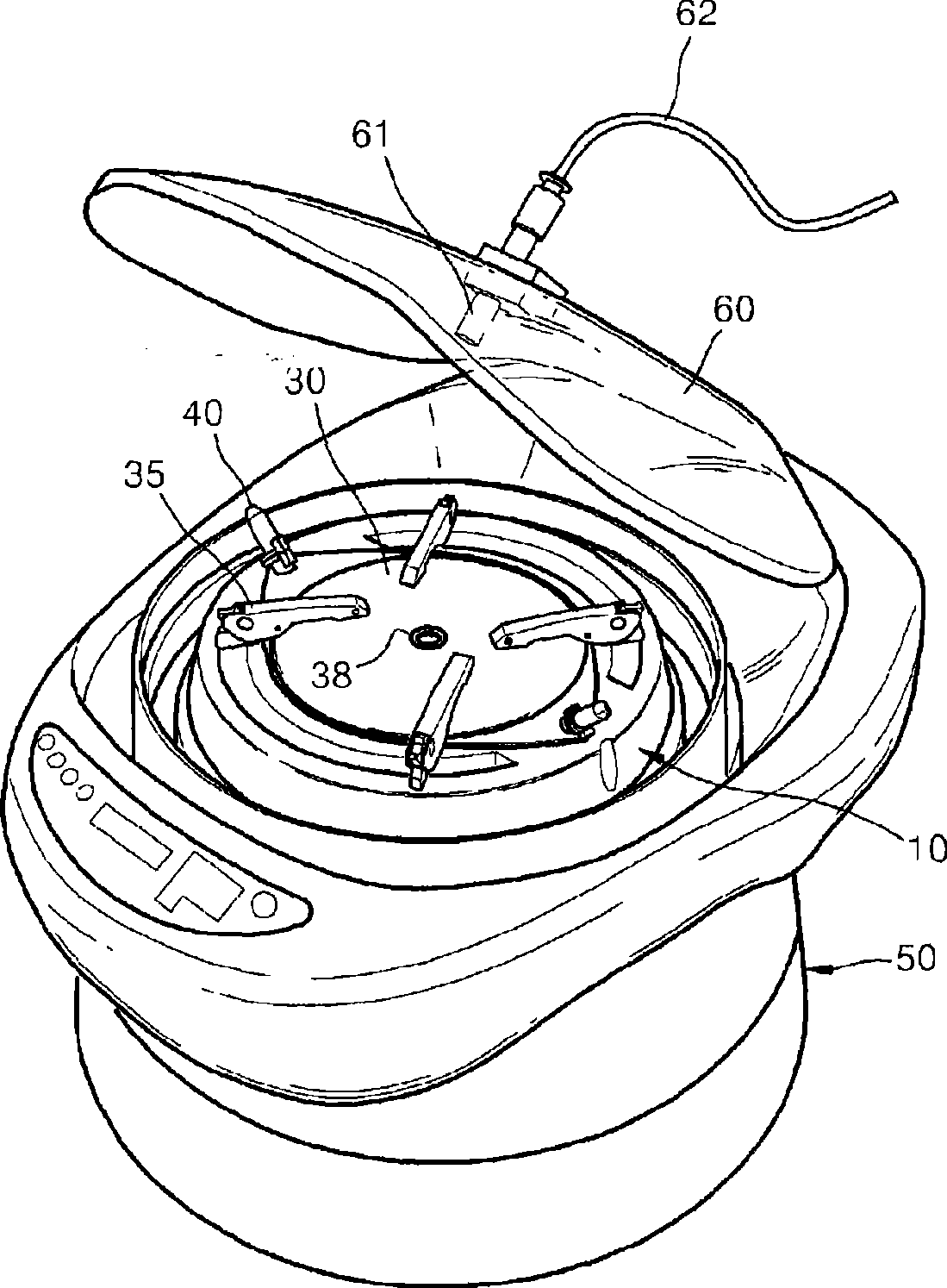

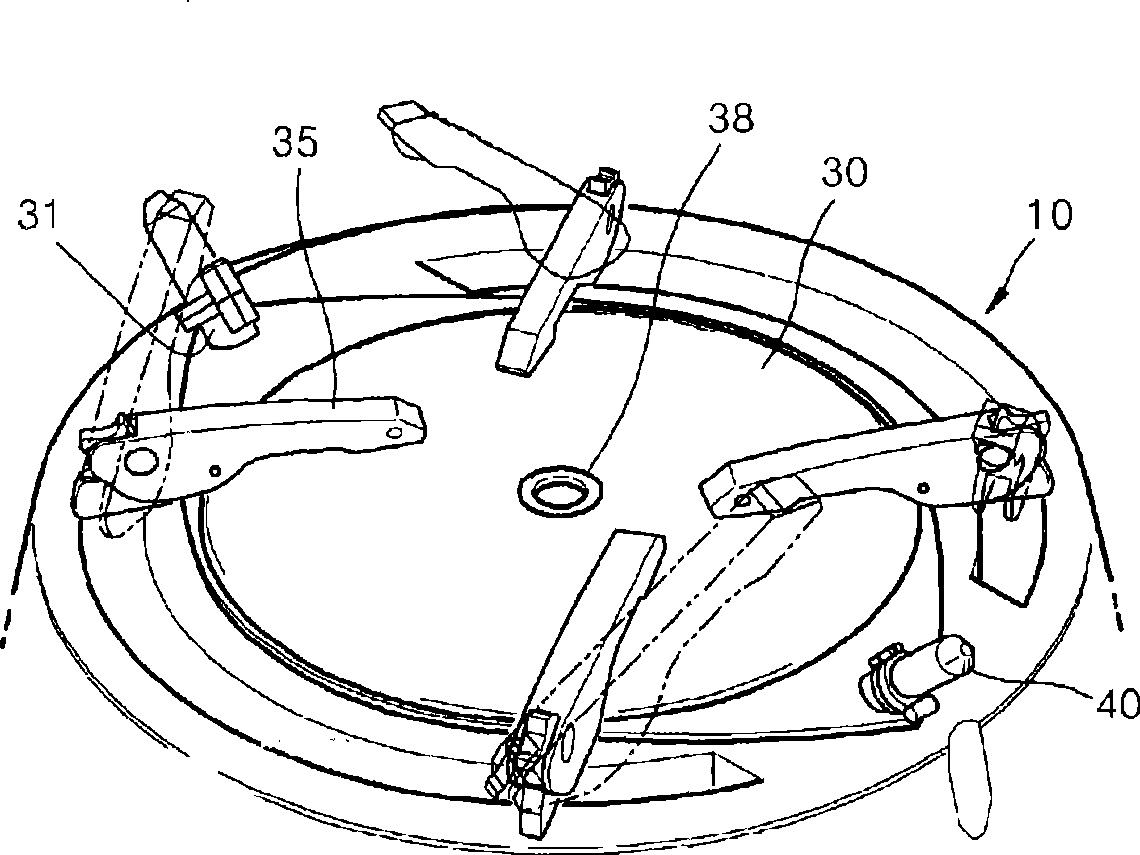

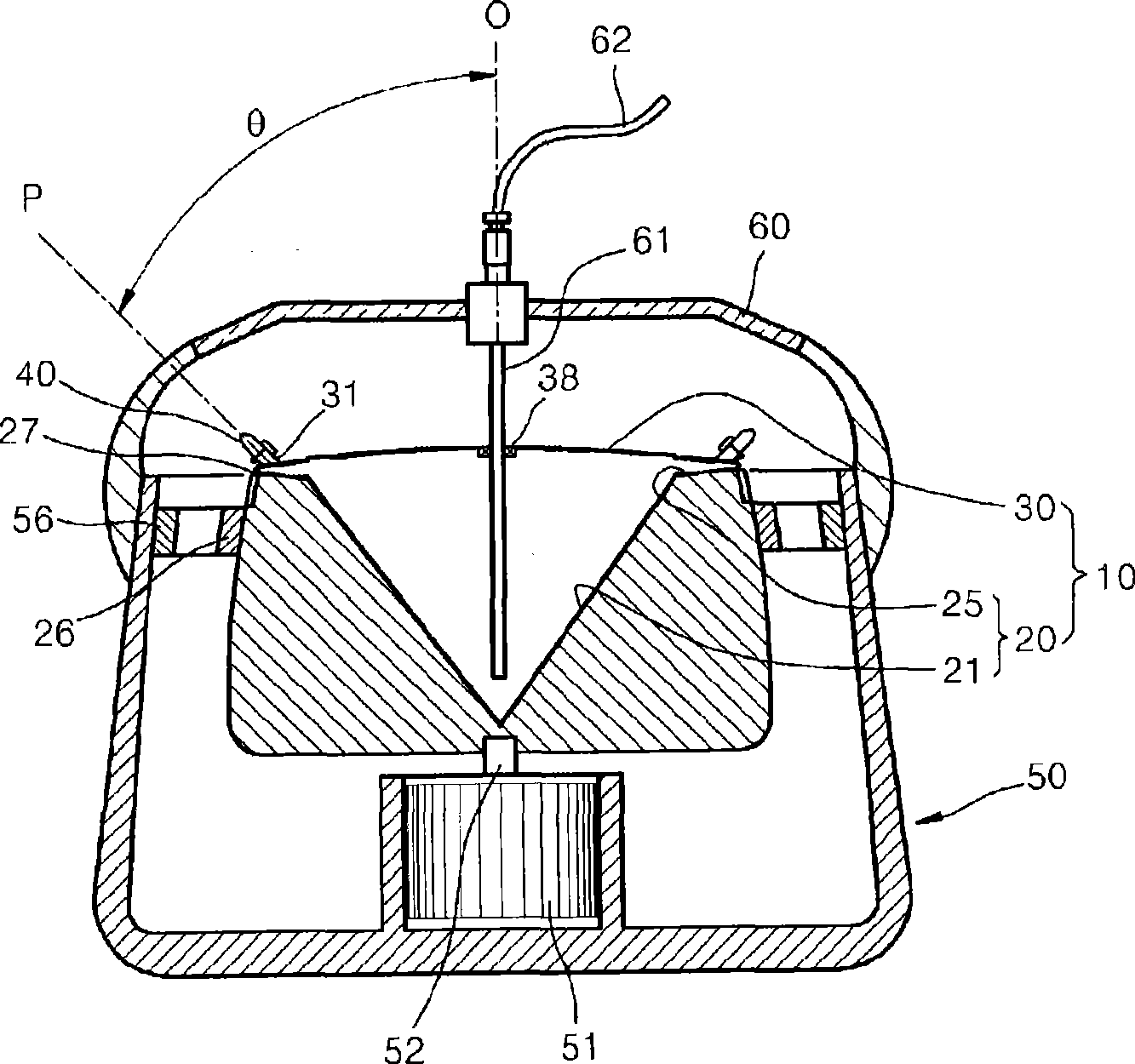

[0065] figure 1 is a perspective view illustrating a centrifugal separator according to an embodiment of the present invention, figure 2 is description figure 1 A partial perspective view of the upper part of the centrifuge, and image 3 is description figure 1 Side cross-sectional view of a centrifuge.

[0066] Figures 1 to 3 The illustrated centrifuge can separate materials by centrifugal force, and can accurately and easily sort and collect partial layers from centrifuged materials, for example, can separate and collect stem cells from centrifuged materials. see Figure 1 to Figure 3 , the centrifuge according to the current embodiment of the present invention includes a spinner 10 rotating around a rotation axis O and a container 40 coupled to the spinner 10 .

[0067] The spinner 10 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com