Turbine blade

A technology for turbine blades and blades, applied in the directions of blade support elements, engine elements, machines/engines, etc., can solve problems such as jeopardizing operational reliability, cracks in the heat shield, and reducing the protection effect of hot exhaust gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

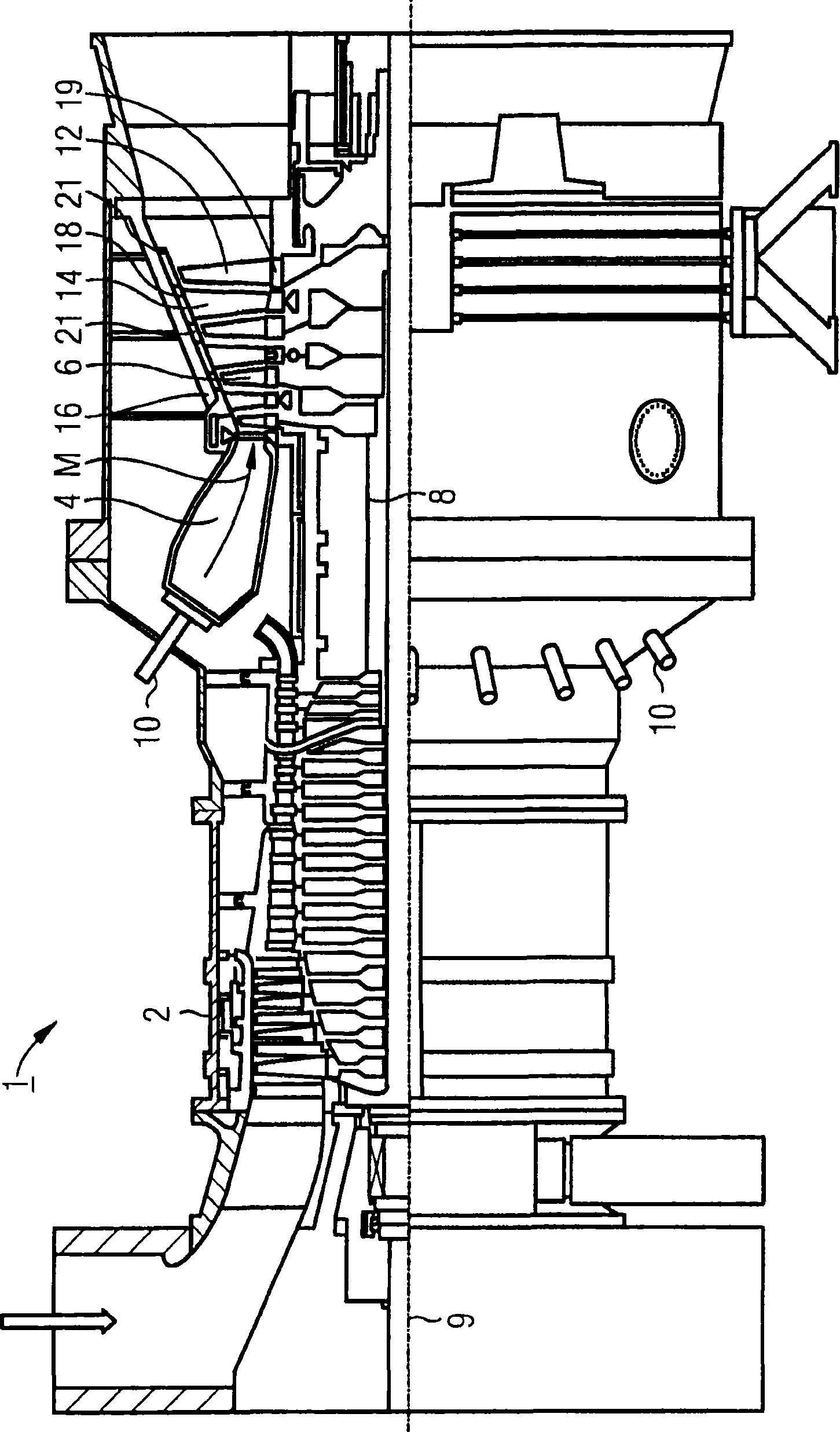

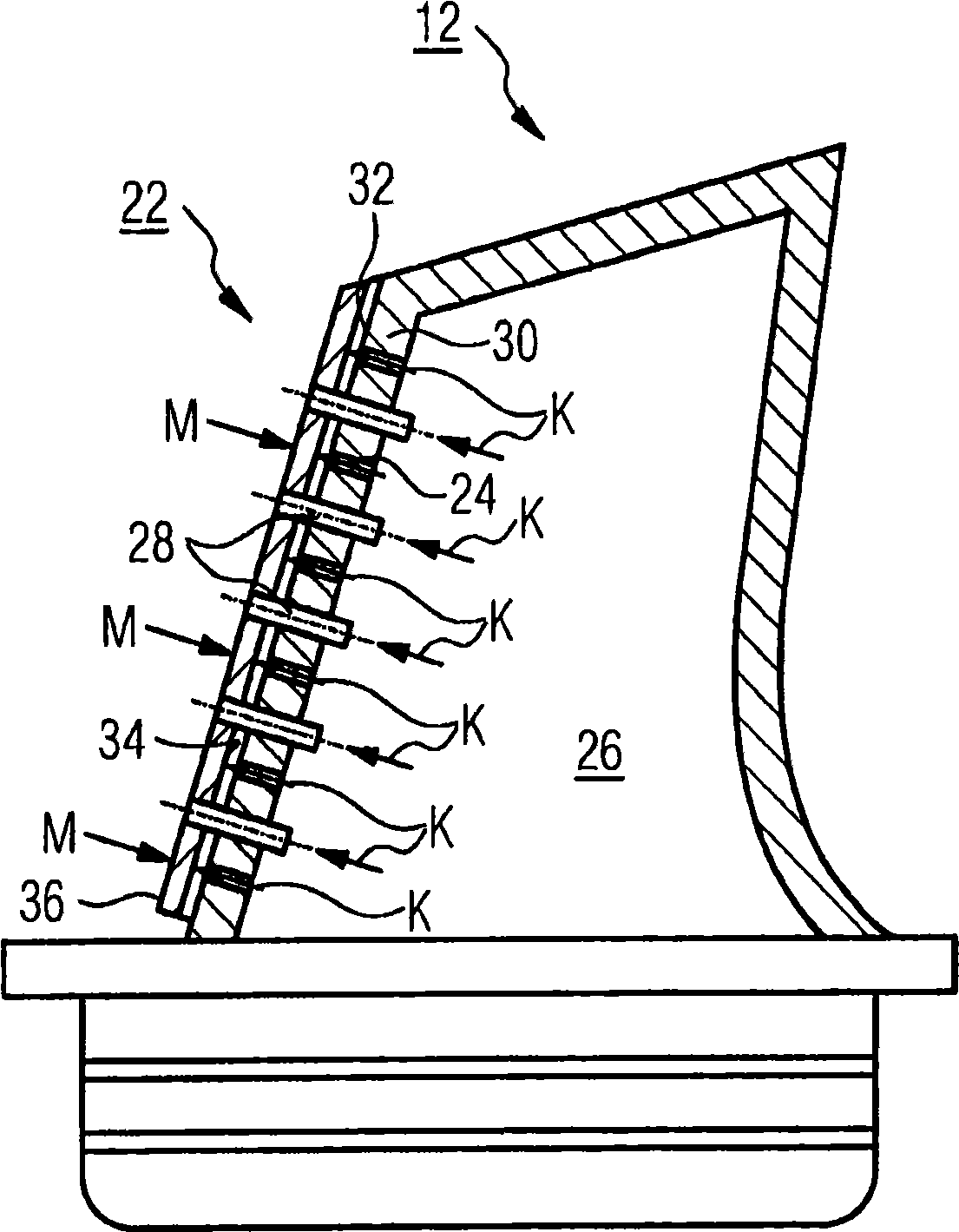

[0033] according to figure 1 The gas turbine 1 has a compressor 2 for the combustion air, a combustion chamber 4 and a turbine unit 6 for driving the compressor 2 and a generator or work machine (not shown). Furthermore, the turbine unit 6 and the compressor 2 are arranged on a common turbine shaft 8 , also referred to as the turbine rotor, to which the generator or power generator is also connected and which surrounds its central axis. 9 is rotatably supported. The combustion chamber 4 , which is designed in the manner of an annular combustion chamber, is equipped with a number of burners 10 for burning liquid or gaseous fuel.

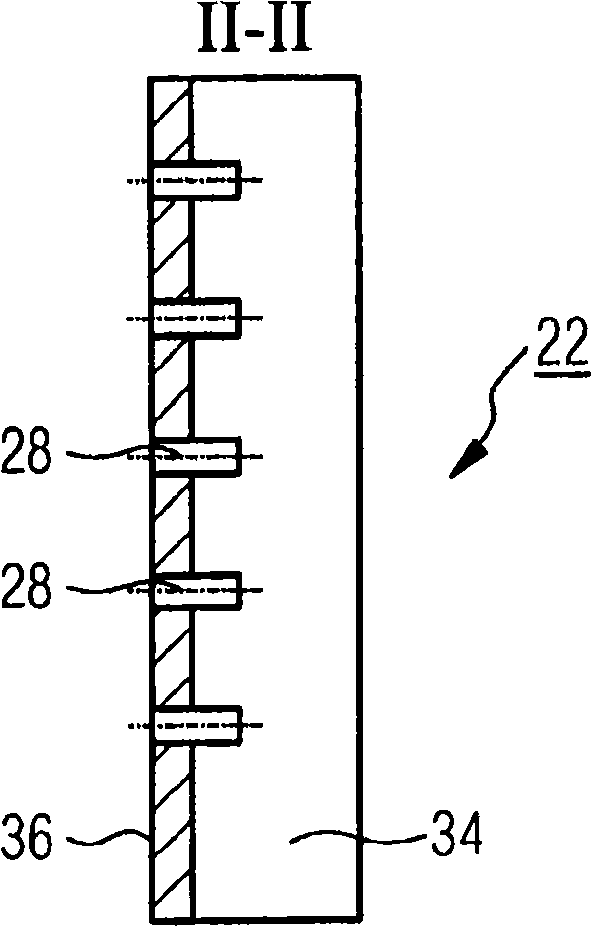

[0034] The turbine unit 6 has a number of rotatable rotor blades 12 connected to the turbine shaft 8 . The rotor blades 12 are arranged annularly on the turbine shaft 8 and thus form a number of rotor blade groups. Furthermore, the turbine unit 6 comprises a number of fixed guide vanes 14 which are likewise fastened annularly to an inner cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com