Digital banner printing carbon ribbon and preparation method thereof

A banner and digital technology, applied in the field of digital banner printing carbon ribbon and its preparation, can solve the problems such as the preparation method of digital banner printing ribbon that has not been seen, and achieve the effect of easy popularization and application, reasonable design, and satisfying digitalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

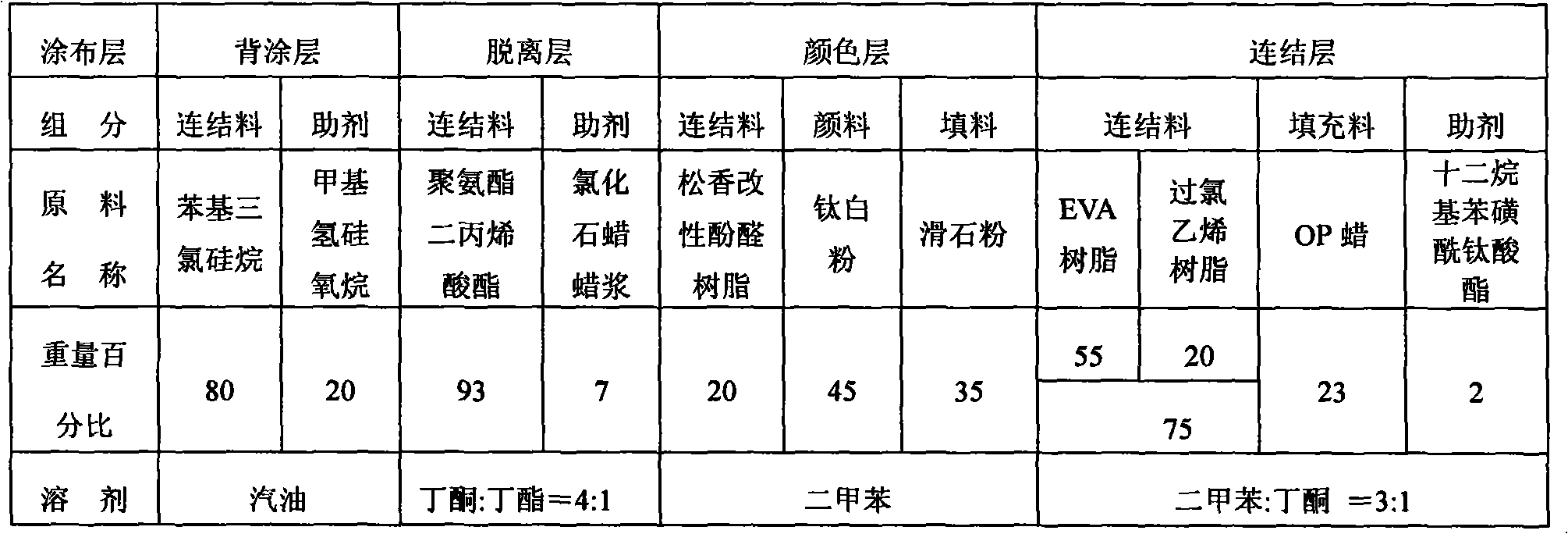

Embodiment 1

[0022]

[0023] Preparation method of digital banner printing ribbon: a. After diluting and mixing the binder with gasoline, add additives and mix evenly within 30 minutes before the trial, then apply it on the surface of the tape base, and dry it at 91°C Form back coating, require this layer thickness 0.4 μ m, enter next operation afterwards; Wherein by weight ratio, the consumption of gasoline is gasoline: connecting material=9: 1;

[0024] b. First dissolve the link material of the release layer with butanone-butyl ester, then add additives in proportion to mix evenly, and then apply it on the other side of the tape base, and dry it at 80°C to form a release layer. The thickness of this layer is 2.0 μm, and enters the next process afterwards; Wherein by weight, the total consumption of butanone and butyl ester is butanone-butyl ester: linking material=5: 1, and in butanone-butyl ester, butanone Ketone: butyl ester = 4: 1;

[0025] c. First dissolve the phenolic resin wi...

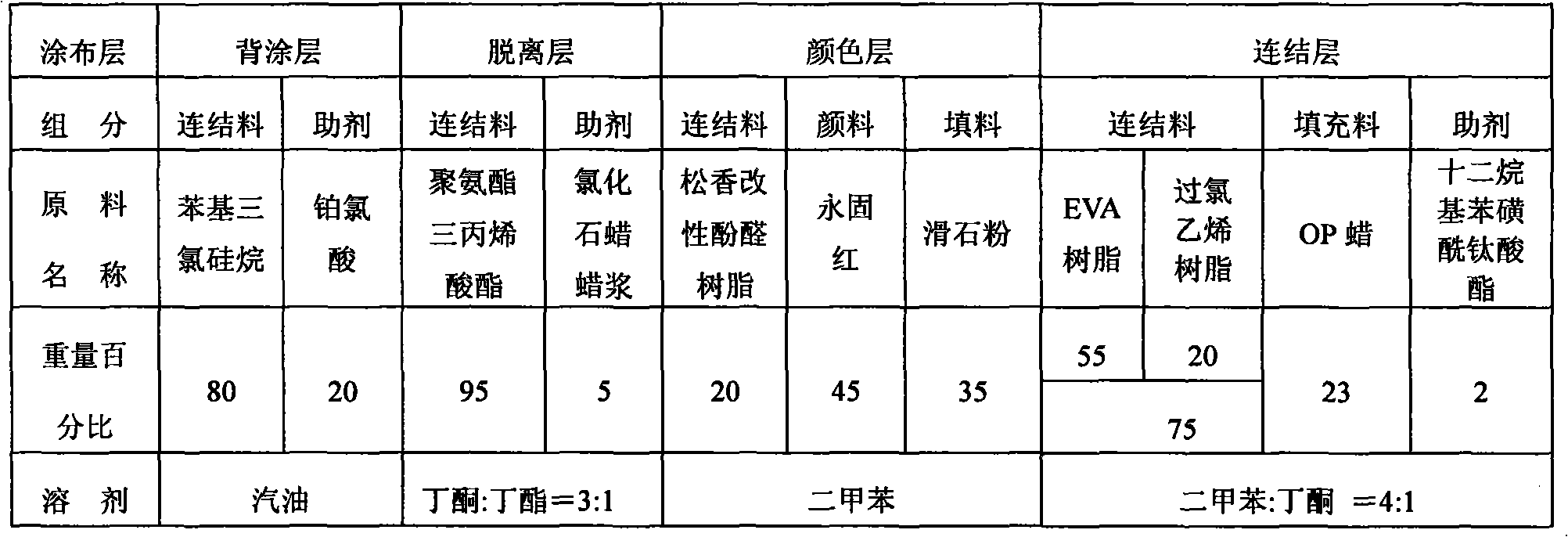

Embodiment 2

[0029]

[0030] In the preparation method of digital banner printing ribbon: in step a, the drying temperature is 80°C, and the back coating thickness is 0.2 μm; in step b, the drying temperature is 60°C, methyl ethyl ketone: butyl ester = 3: 1, and the thickness of the release layer 1 μm; in step c, the drying temperature is 80° C., and the thickness of the color layer is 8 μm; in step d, the drying temperature is 40° C., xylene: butanone=4: 1, and the thickness of the connecting layer is 4.0 μm; others are the same as in Example 1.

[0031] In this embodiment, the tape base is a biaxially stretched PET film with a thickness of 4 μm, and the total thickness of the digital banner printing ribbon is 17.2 μm.

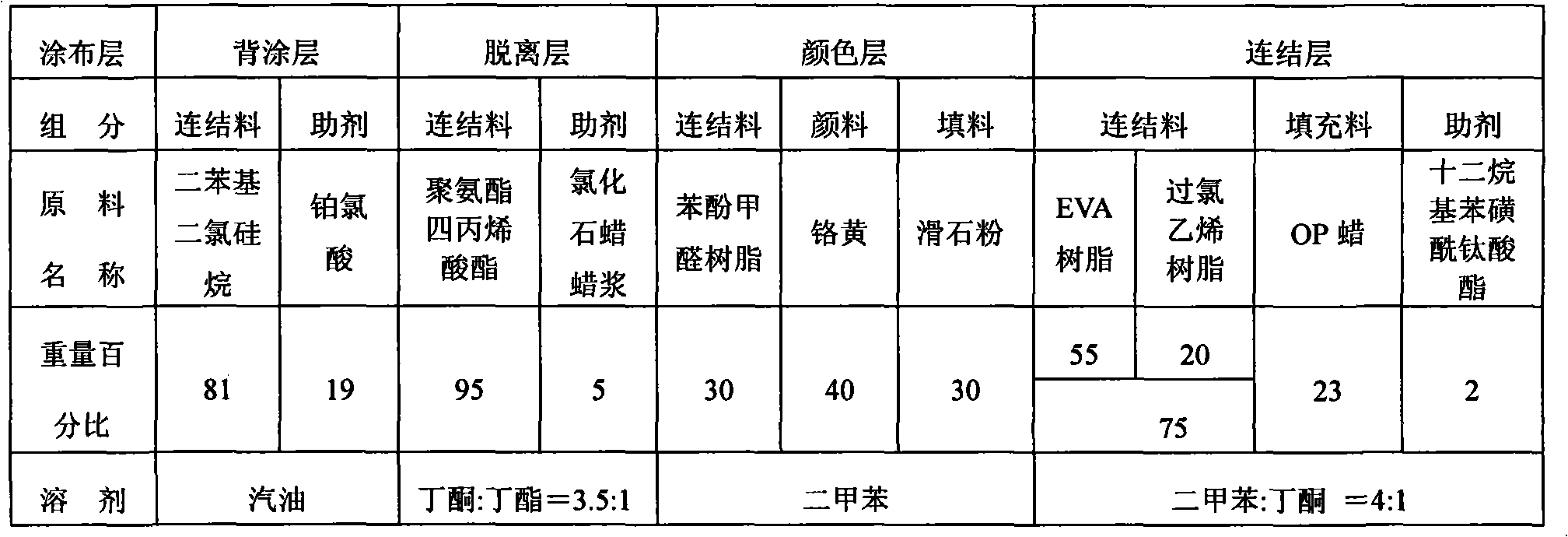

Embodiment 3

[0033]

[0034] In the preparation method of digital banner printing carbon ribbon: in step a, the drying temperature is 81 ° C, the back coating thickness is 0.5 μm; in step b, the drying temperature is 60 ° C, methyl ethyl ketone: butyl ester = 3.5: 1, and the thickness of the release layer 3 μm; in step c, the drying temperature is 100° C., and the thickness of the color layer is 20 μm; in step d, the drying temperature is 60° C., xylene: butanone=4: 1, and the thickness of the connecting layer is 10 μm; others are the same as in Example 1.

[0035] In this embodiment, the tape base is a biaxially stretched PET film with a thickness of 6 μm, and the total thickness of the digital banner printing ribbon is 39.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com