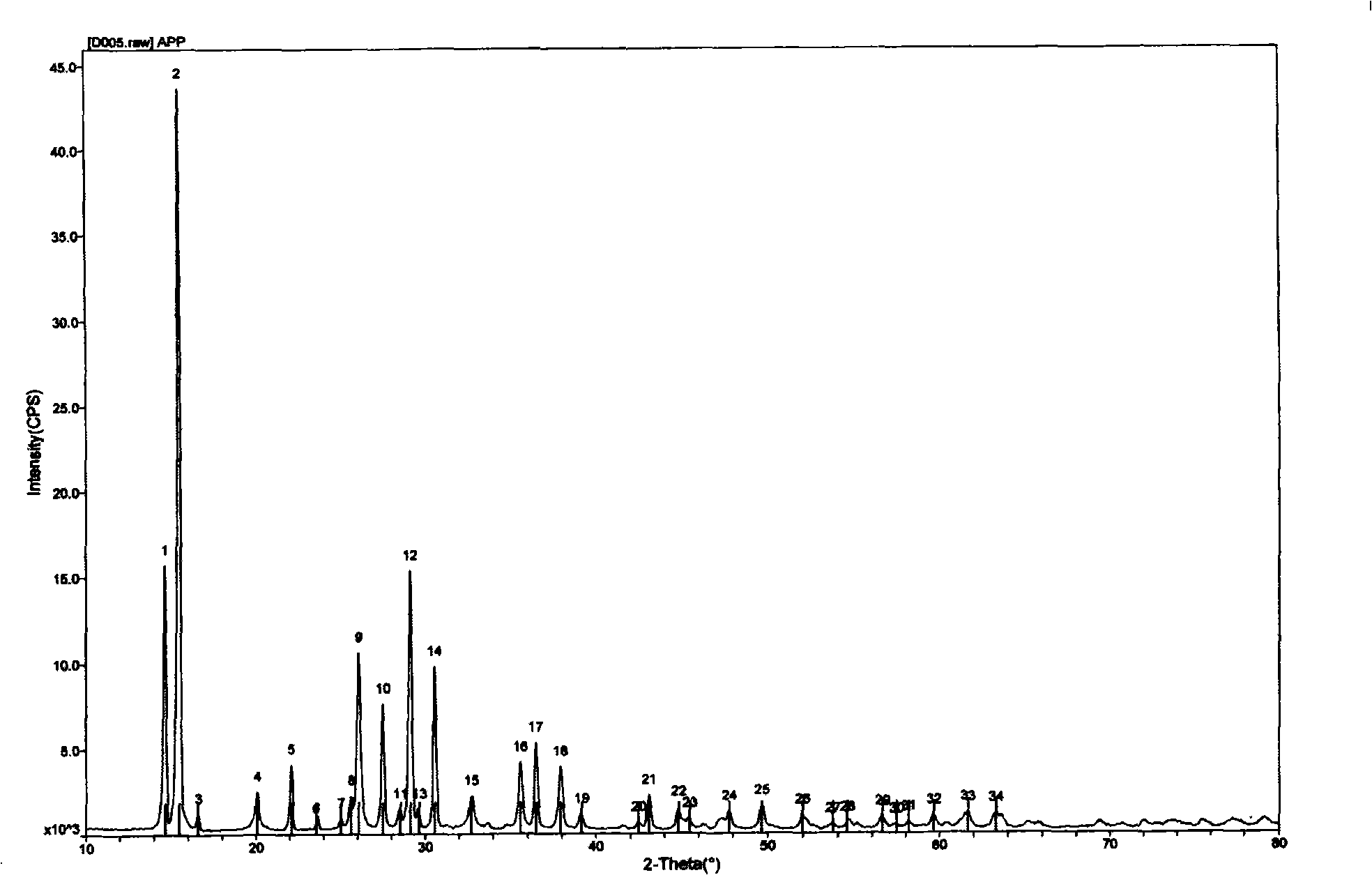

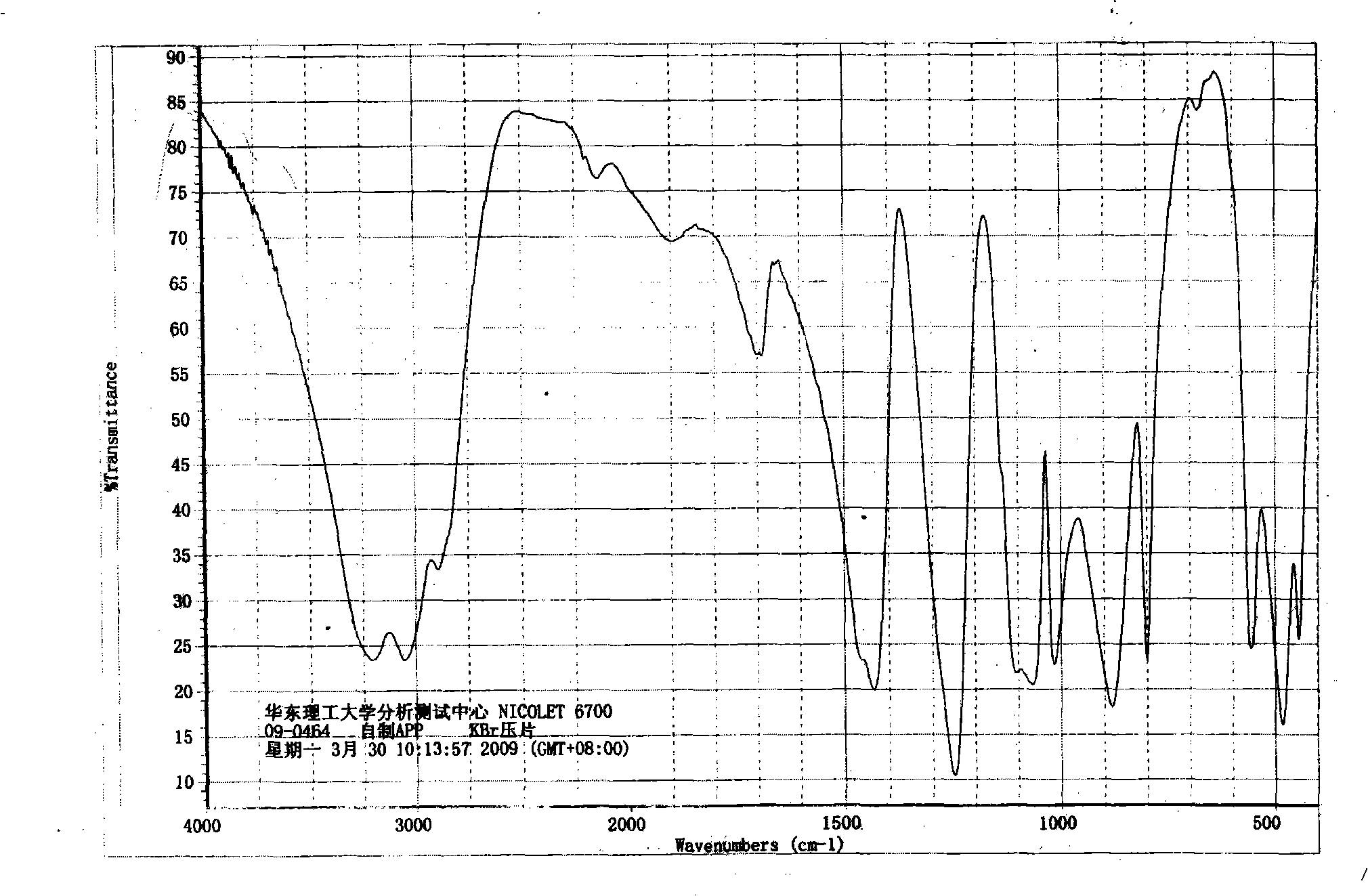

Preparation method of crystallization II-type ammonium polyphosphate with high degree of polymerization

A high degree of polymerization, ammonium polyphosphate technology, applied in chemical instruments and methods, single crystal growth, phosphorus compounds, etc., can solve problems such as the preparation method of APP with a high degree of polymerization without crystal II

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

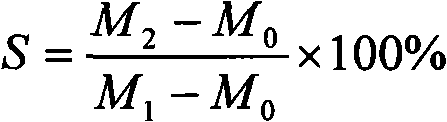

Embodiment 1

[0028] Diammonium hydrogen phosphate 50kg, urea 4.4kg, melamine 8.2kg, diammonium hydrogen phosphate is first added to the reactor, and the temperature is raised to 160°C. Ammonia gas, or continuously replace with air to discharge water; after reaching 180°C, gradually add urea and stir within half an hour, and continuously discharge the gas released by the reaction. After adding urea, add melamine at 200°C to 250°C at one time and stir, then gradually raise the temperature. Start timing when it rises to 260°C, keep the temperature for 30 minutes, gradually increase the stirring power, and discharge the gas released by the reaction. After 60 minutes, feed ammonia into the reactor with a flow rate of 6m 3 / h, the product is initially solidified after 10 minutes, cooled to 210 ° C, and then matured for 1 hour, the ammonia gas flow rate is 2m 3 / h. 99.0% of the obtained product is crystalline type II ammonium polyphosphate, the average degree of polymerization is 1766, and the...

Embodiment 2

[0030] In this example, the heat preservation reaction temperature is 280°C, and the time is 60 minutes. The rest of the operations are the same as in Example 1, and 99% of the obtained product is crystalline type II ammonium polyphosphate, the average degree of polymerization is 1836, and the 1% thermal weight loss temperature is greater than 275 ℃ (weight loss rate is less than 0.5%).

Embodiment 3

[0032] In this example, the heat preservation reaction temperature is 300°C, and the time is 40 minutes. The remaining operations are the same as in Example 1, and 99% of the obtained product is Type II ammonium polyphosphate, with an average degree of polymerization of 1917, and a temperature of 1% thermal weight loss greater than 285°C (The weight loss rate is less than 0.5%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

| Water soluble | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com