Styrene monomer containing alkyl sodium (potassium) thiosulfate and preparation method thereof

A technology of alkyl sodium thiosulfate and sodium thiosulfate, applied in organic synthesis and polymer fields, can solve the problem that mercapto groups and polymerizable monomers cannot exist stably at the same time, and achieve simple structure, low cost, and easy preparation and storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

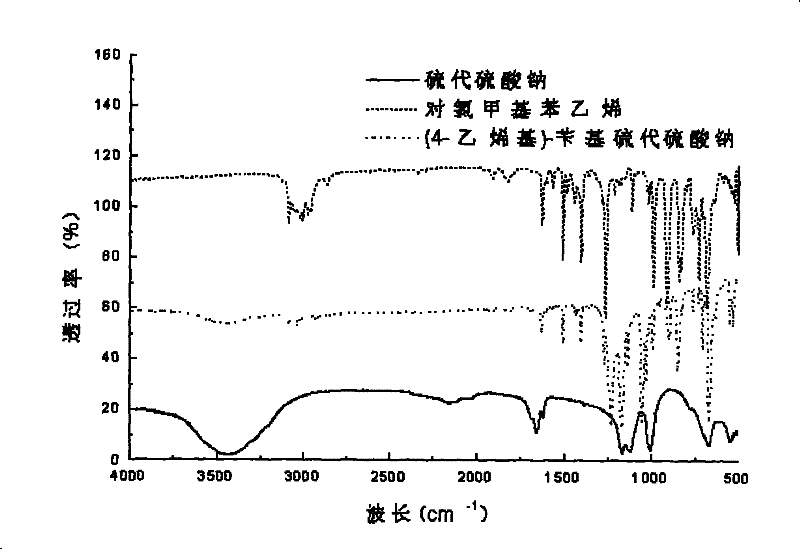

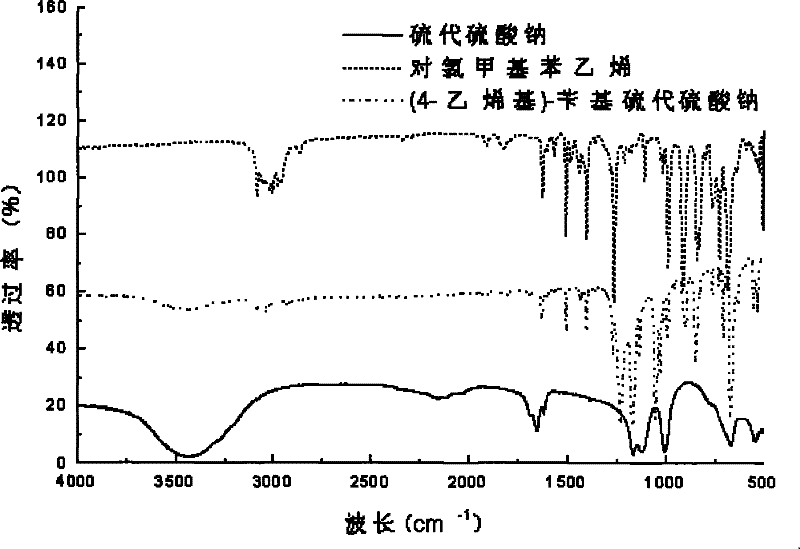

Embodiment 1

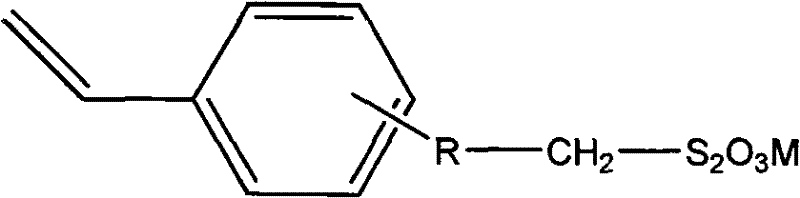

[0024] Add 3.00g of PEO400, 24.817g (0.1mol) of sodium thiosulfate and 30mL of water into a 250mL round bottom flask equipped with a magnetic stirring bar, and stir well. Add 20.349g (0.12mol) p-chloromethylstyrene (mass fraction 90%) and 10mL ethanol to a 50mL beaker, stir well and pour into a constant pressure funnel, then drop it into a 250mL round bottom flask. The reaction was stopped after 6 hours at room temperature. Use a rotary evaporator to spin off ethanol and part of the water to obtain a solid. The solid was collected by suction filtration and rinsed with a small amount of cold water and petroleum ether to remove unreacted p-chloromethylstyrene, sodium thiosulfate and PEO400 to obtain a pure product—(4-vinyl)-benzyl sodium thiosulfate , the structural formula is as follows:

[0025]

Embodiment 2

[0027] Add 10.00 g (0.18 mol) of potassium hydroxide, 9.896 g (0.1 mol) of 1,2-dichloroethane and 40 mL of absolute ethanol into a 250 mL three-neck flask equipped with a magnetic stirring bar, and stir evenly. Add 12.015g (0.1mol) 4-hydroxystyrene and 20mL absolute ethanol to a 50mL beaker, stir well and pour into a constant pressure funnel, install a spherical condenser and a constant pressure funnel on a 250mL three-necked bottle, and heat After reaching the reflux temperature, drop liquid, stop the reaction after reacting for 14 hours, remove the generated salt by filtration, and obtain the etherified product. Use a rotary evaporator to spin off half of the solvent at room temperature for later use.

[0028] Add 3.00g of PEO 400, 30.00g (0.12mol) of sodium thiosulfate and 30mL of water into a 250mL round bottom flask equipped with a magnetic stirring bar, and stir evenly. Pour the ethanol solution of the synthesized etherified product into a constant pressure funnel, and ...

Embodiment 3

[0031] Put a magnetic stirring bar into a 250mL three-necked flask equipped with a spherical condenser, add 11.916g (0.1mol) 4-aminostyrene, 9.896g (0.1mol) 1,2-dichloroethane, 15.178g (0.15 mol) triethylamine and 70 mL of absolute ethanol, heated to reflux temperature and reacted for 8 hours to stop the reaction, and filtered to remove the generated salt to obtain a nucleophilic substitution product. Use a rotary evaporator to spin off half of the solvent at room temperature for later use.

[0032] Add 3.00g of PEO400, 30.00g (0.12mol) of sodium thiosulfate and 30mL of water into a 250mL round bottom flask equipped with a magnetic stirrer, and stir evenly. Pour the ethanol solution of the synthesized nucleophilic substitution product into a constant pressure funnel, and then drop it into a 250mL round bottom flask. The reaction was stopped after 6 hours at room temperature. The ethanol was spun off with a rotary evaporator to obtain a solid. The solid was collected by suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com