Yarn feeding device of weaving machine

A technology of looms and yarn clearers, which is applied in the fields of weaving, knitting, textiles and papermaking, etc. It can solve the problems of cloth surface structure pollution, lower production efficiency, clean air pollution caused by hair dust, etc., so as to reduce production costs and improve The effect of simple production efficiency and technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

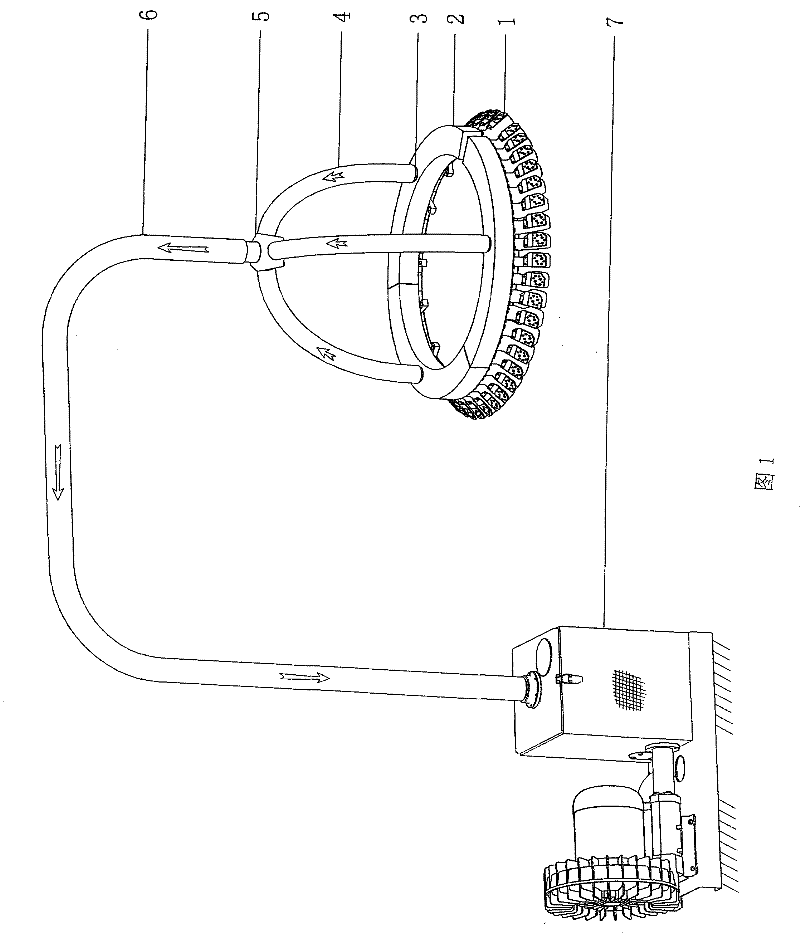

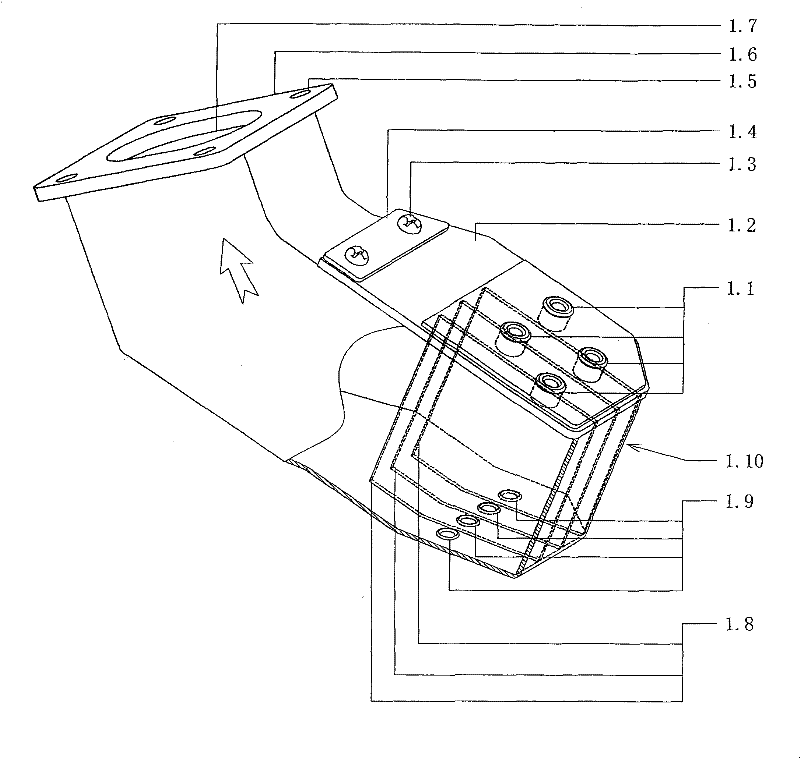

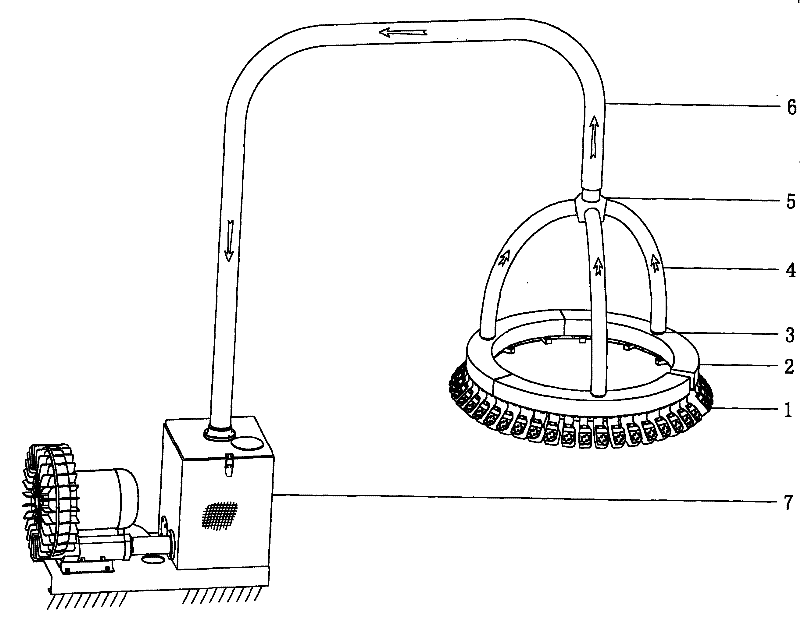

[0011] see figure 1 , the yarn-feeding device of the loom that the present invention relates to is mainly composed of a yarn clearer 1 (magnetic eyes can be distributed according to the number of yarns in a mold), an annular air groove 2, an annular air groove suction / suction port 3, a suction The air pipe 4, the exhaust pipe joint 5, the dust suction pipe 6 and the vacuum cleaner 7 are formed. There are several yarn clearers 1, and several yarn clearers 1 are evenly fixed on the lower plate of the ring-shaped wind groove 2 with screws, and the ring-shaped wind groove 2 is fixed on the top of the cylinder loom, and the ring-shaped wind groove 2 is fixed on the upper end of the cylinder loom. There are three (or more than three) annular air slot suction / suction outlets 3 evenly distributed on the upper pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com