Method and structure for constructing permanent retaining wall by woven fabric bags filled with soil

A woven bag and retaining wall technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of woven bags such as easy weathering, poor durability, and project waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

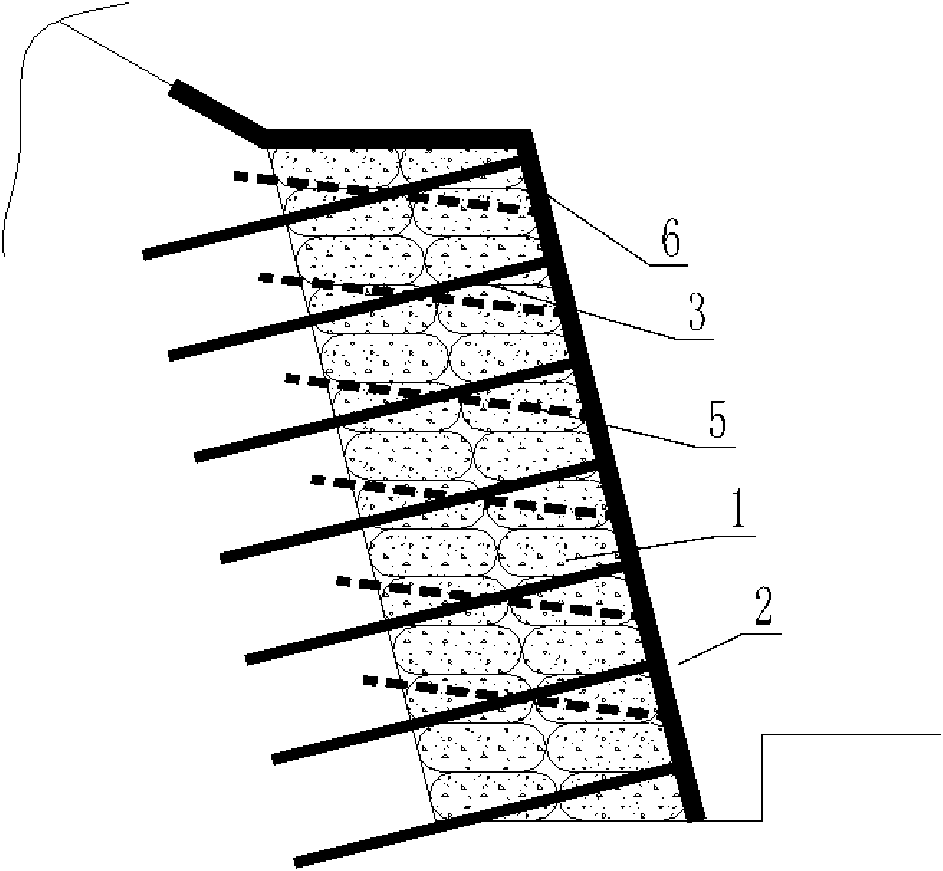

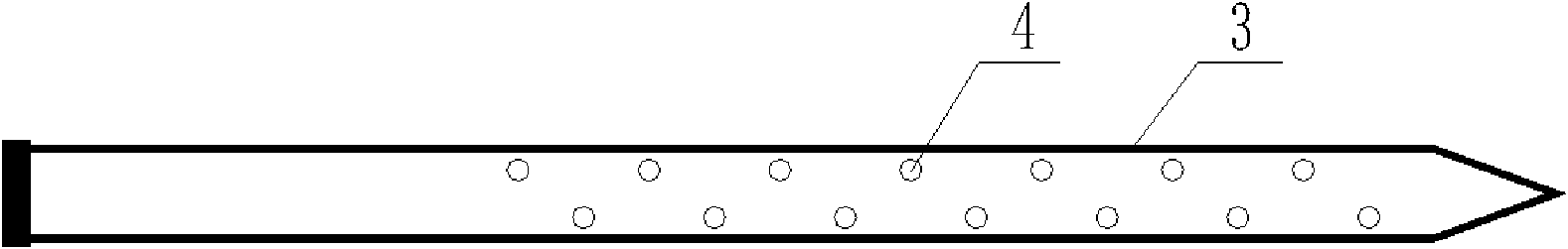

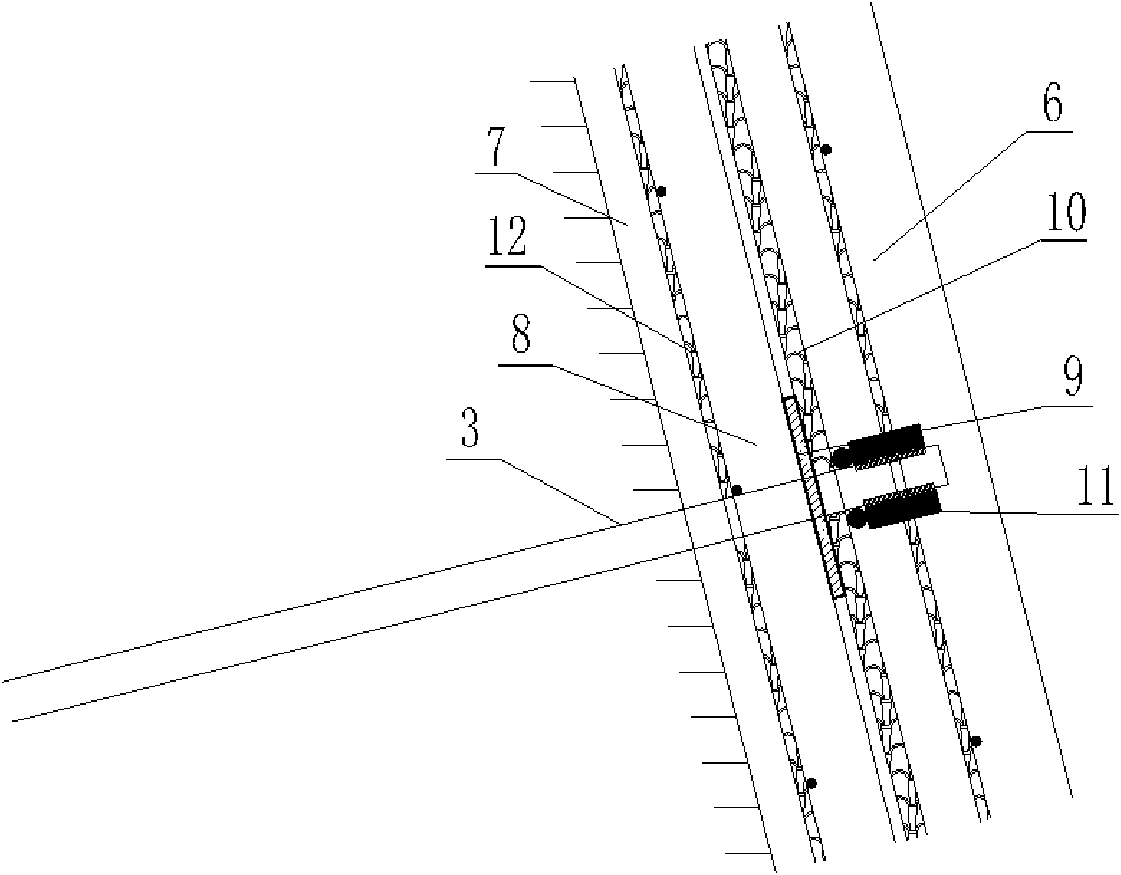

[0024] Embodiment of the present invention: in the road landslide emergency rescue project, the width of the retaining wall is first determined according to the height of the retaining wall to be built, and the foundation of the retaining wall is excavated according to the width of the designed retaining wall. The woven bags 1 are then filled with geotechnical woven bags 1 to obtain the geotechnical woven bag retaining wall 2, and the landslide is backfilled to repair the roadbed and restore road traffic; then insert flower tubes 3 into the geotechnical woven bag retaining wall 2 Cement slurry or cement mortar is pressure-injected into flower tube 3, the strength of the injected cement slurry or cement mortar is greater than or equal to 20MPa, and the grouting pressure is greater than or equal to 0.2MPa. And make reinforced concrete surface layer 6 on the outer side of geotechnical woven bag retaining wall 2 and wall top, obtain permanent retaining wall.

[0025] When the geot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com