Solid state light source device

A technology of solid-state light sources and light guides, which is applied in the direction of light sources, point light sources, lighting devices, etc., can solve the problems of limited luminous brightness and difficulty in achieving efficiency, and achieve the effect of increasing the effective luminous area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

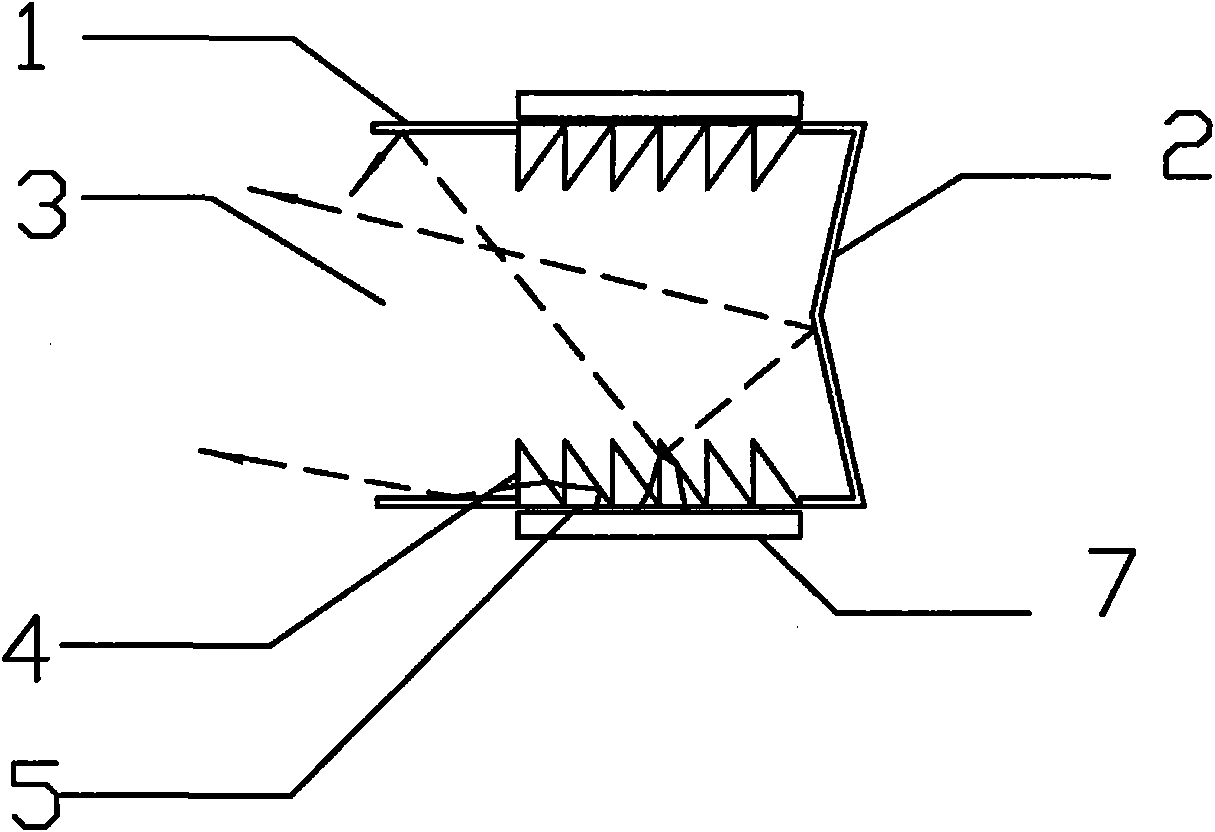

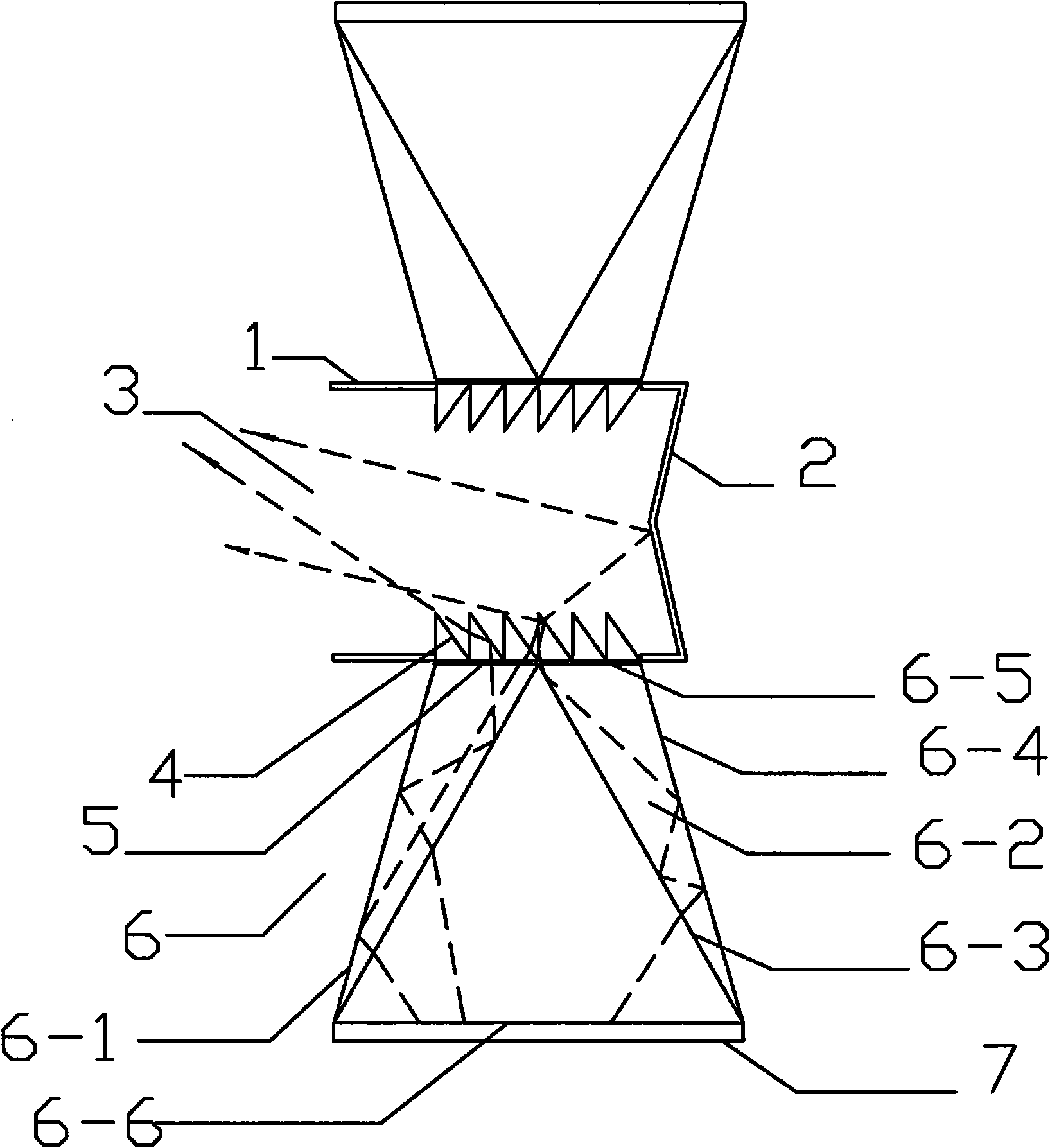

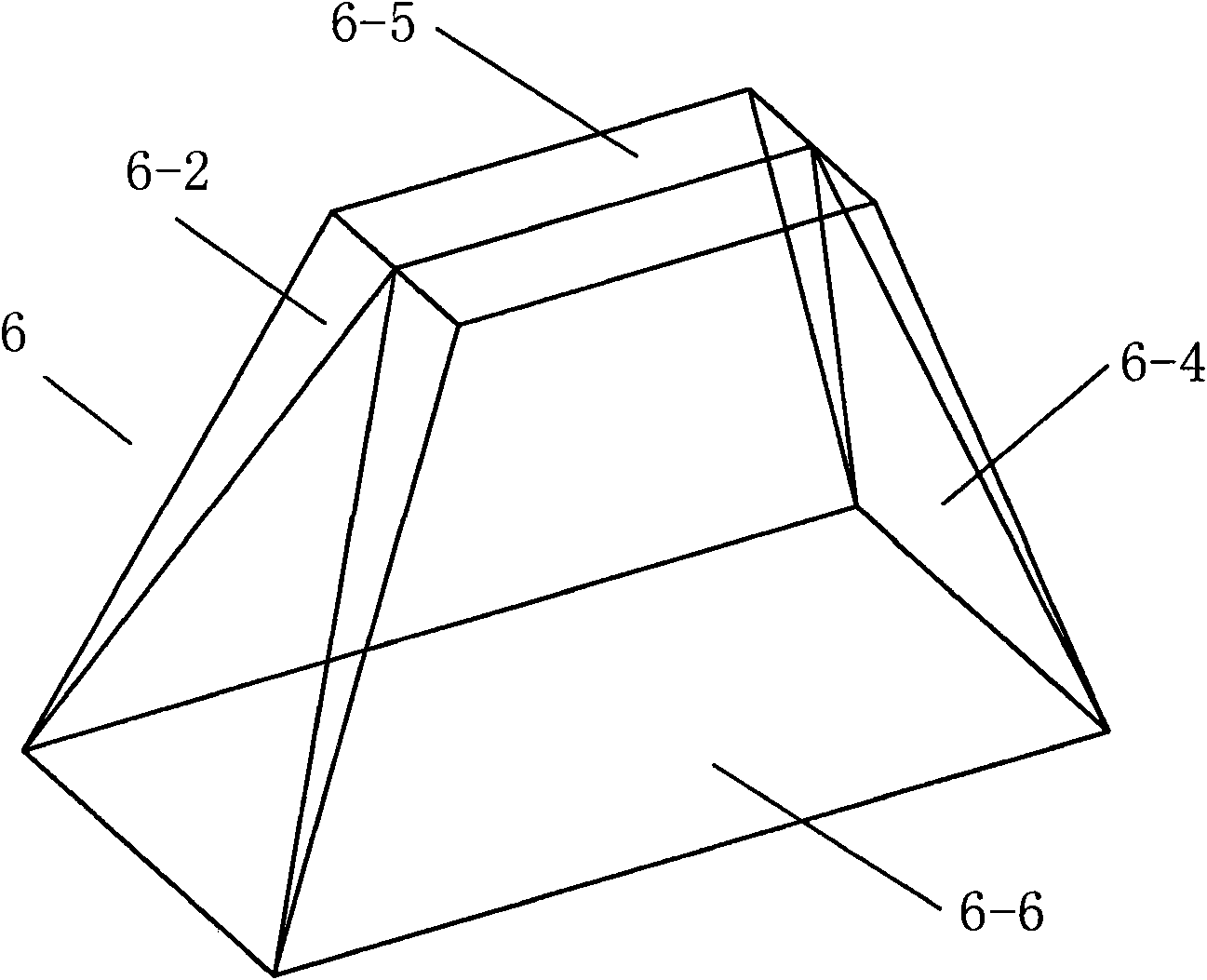

[0025] In the present invention, a prism-shaped light guide 6 with a light incident area larger than the light-emitting area is provided between the light entrance 5 of the optical member 1 and the surface light guide 7. After the light emitted by the surface luminous body 7 passes through the prism-shaped light guide 6 , and then refracted or totally reflected by the light guide prism 4, reflected by the reflector or directly emitted from the light outlet 3 of the optical member 1, the effective light emission of the surface luminous body 7 is increased without changing the size of the optical member 1 and the light inlet 5 Area, or maintain the same effective light-emitting area of the surface luminous body, and can reduce the light entrance area of the solid-state light source device, that is, reduce the volume of the hexahedral optical component and the light exit area, making it closer to the ideal point light source.

[0026] Such as figure 2 As shown, a solid-state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com