Electrogalvanizing zinc coating thickness BP neural network control method and application in PLC thereof

A BP neural network and control method technology, applied in the application field of BP neural network control method on PLC, can solve the problems of poor anti-interference, poor fault tolerance, and large variation range of mathematical models, etc., to achieve suppression of industrial interference, high The effect of precision control, good precision and fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

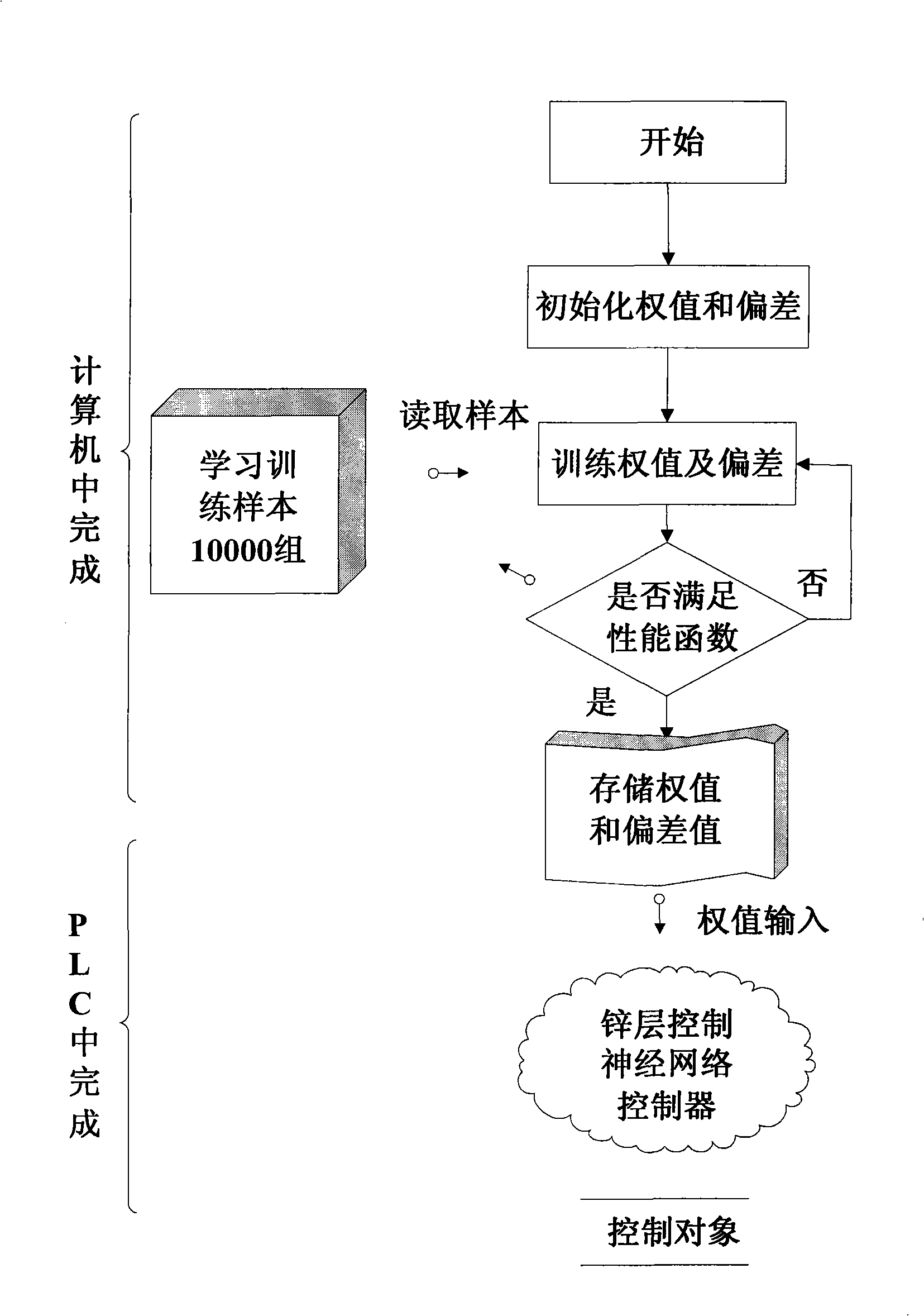

[0031] Such as figure 1 Shown, the PLC control method of the electrogalvanized zinc layer thickness based on BP neural network algorithm of the present invention may further comprise the steps:

[0032] A. Training sample data collection

[0033] Collect a certain number of actual production data samples in the electro-galvanizing production line, about 10,000 samples, and ensure the ergodicity of the data. Samples are collected in the form of input vectors and output vectors. One input vector and one corresponding output vector form a set of sample data. The input vector includes elements such as the thickness of the upper coating, the thickness of the lower coating, the width of the steel strip and the total current of the plating tank; the output vector includes two elements, the calculation speed of the upper coating thickness and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com