Polyacetal resin composition and molded article thereof

A technology of polyacetal resin and polyacetal copolymer, applied in the field of polyacetal resin composition, can solve the problems of reducing formaldehyde and the like, and achieve the effects of reducing the amount of production and inhibiting exudation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

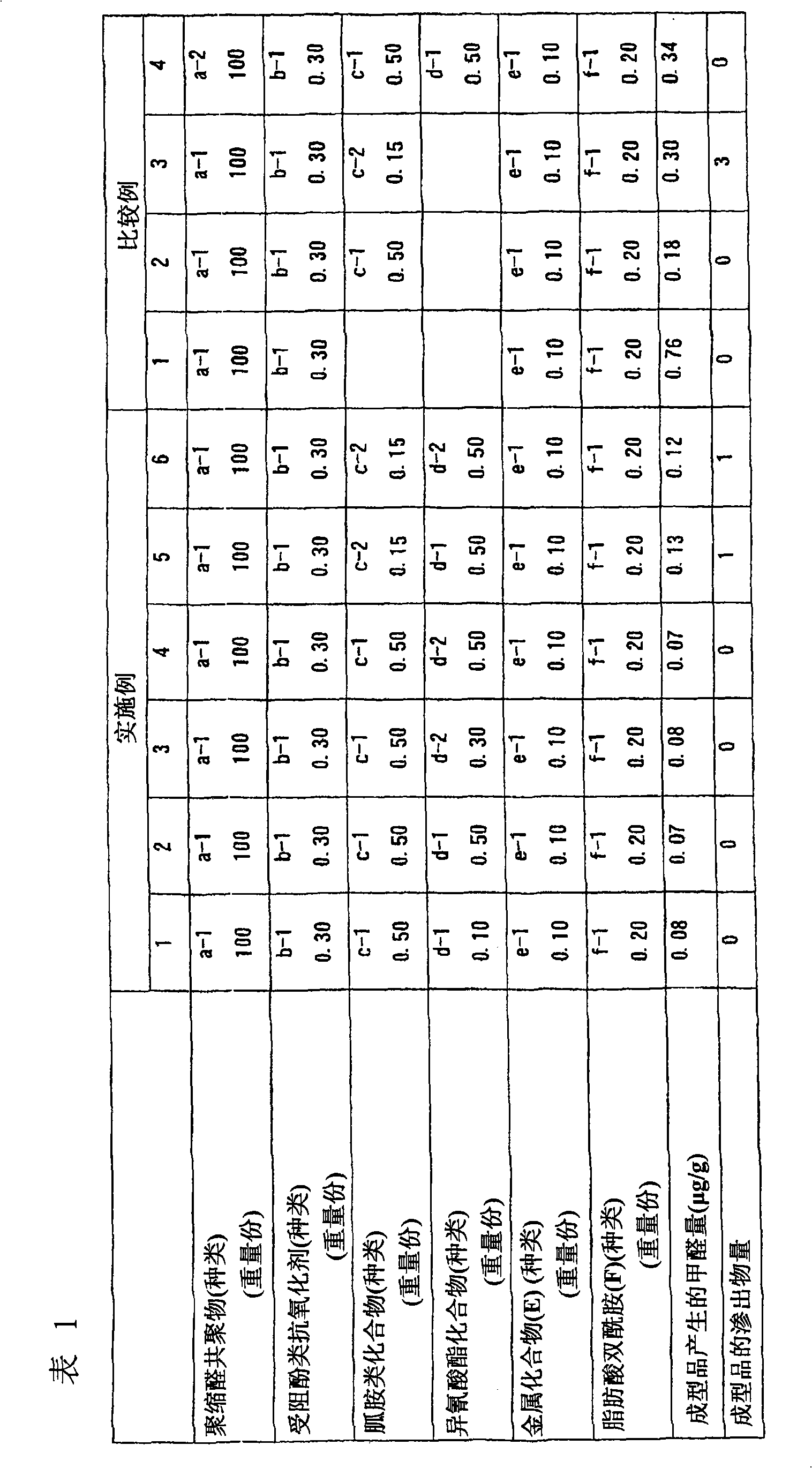

[0108] According to the composition shown in Table 1, the hindered phenolic antioxidant (B), formaldehyde trapping agent (guanamine compound) (C), isocyanate compound (D) and other compounds are blended with the polyacetal copolymer (A) to use A 30mm twin-screw extruder was melted and kneaded to prepare a granular composition. Next, using an injection molding machine, the test piece was molded from the pellets under the molding conditions (1) described above, and the amount of formaldehyde generated from the molded product was measured. Using an injection molding machine, a test piece was molded in accordance with the molding condition (2) described above, and the exudation of the molded product was observed. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com