Paper feeding speed difference adjusting mechanism for sheet-fed paper guide

A technology of adjusting mechanism and paper feeding machine, which is applied in the direction of transportation and packaging, object supply, pile separation, etc., to achieve the effect of improving quality, high-speed and stable paper feeding, and consistent speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

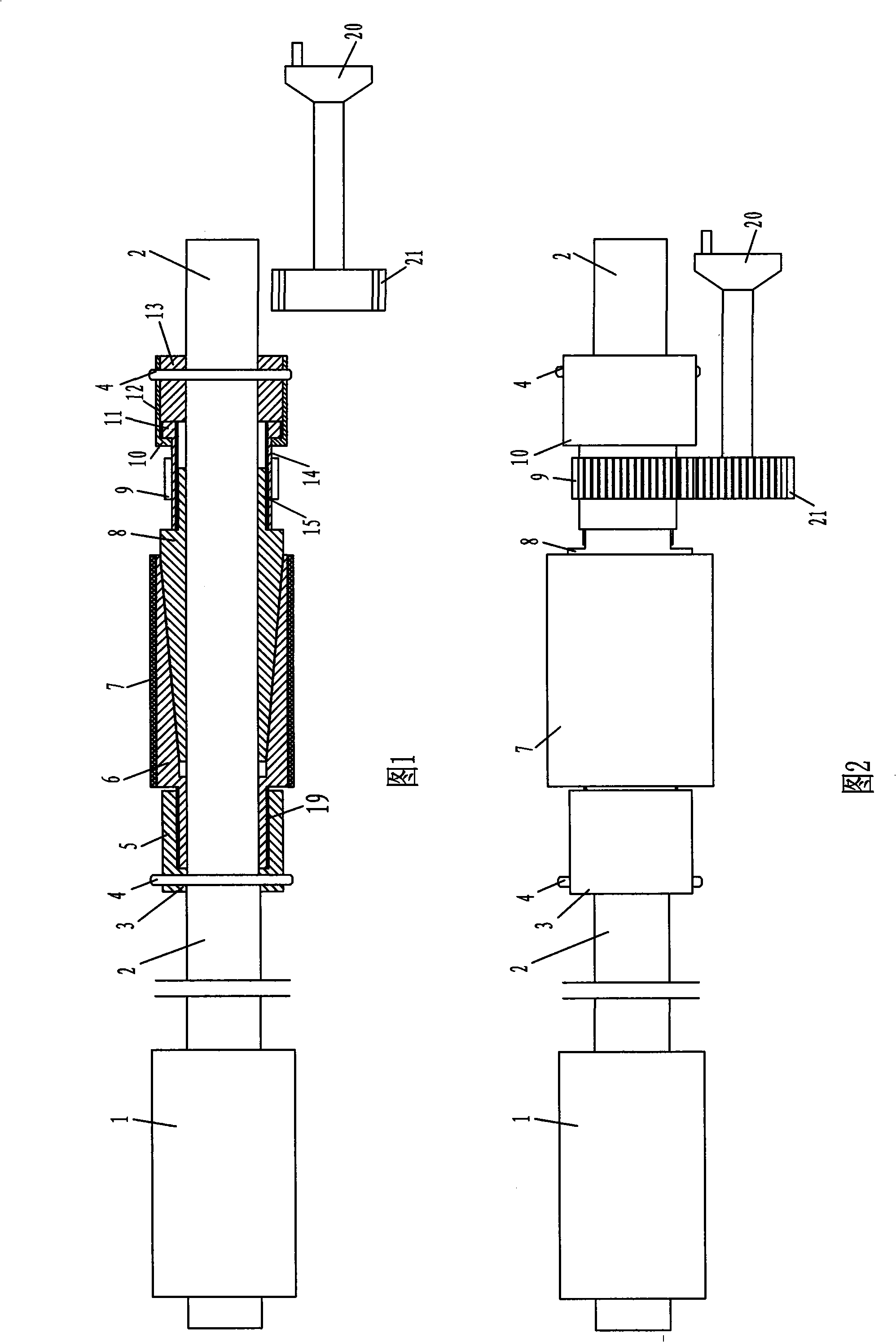

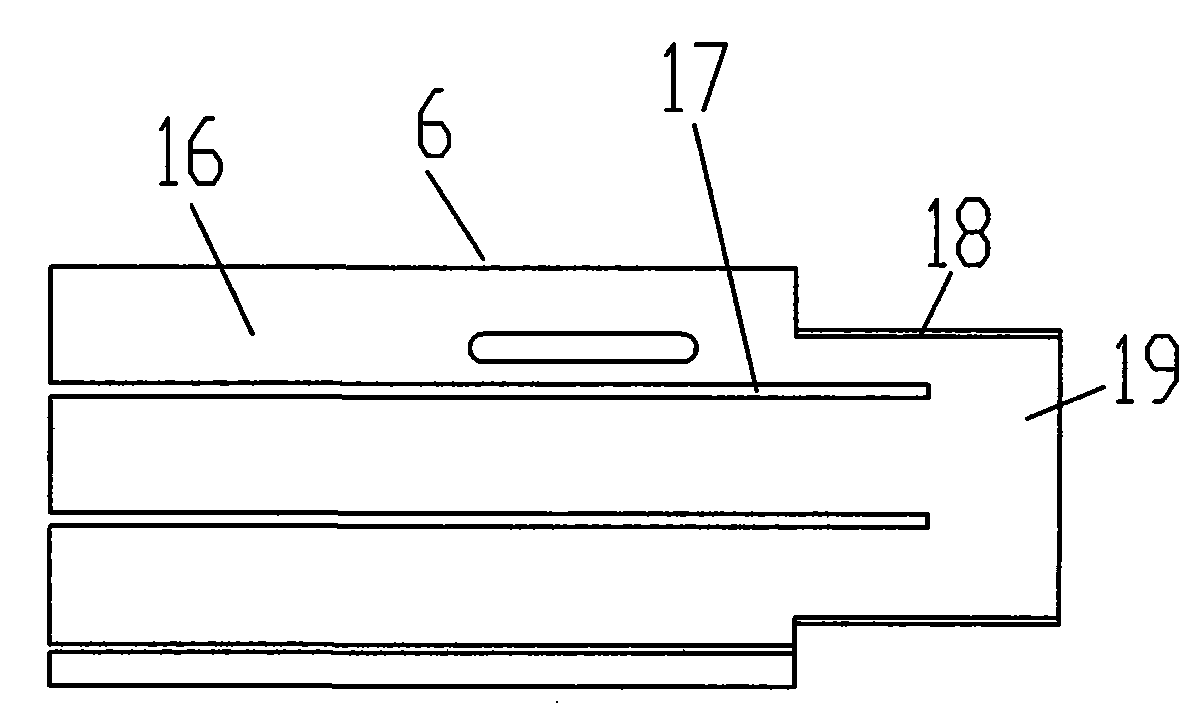

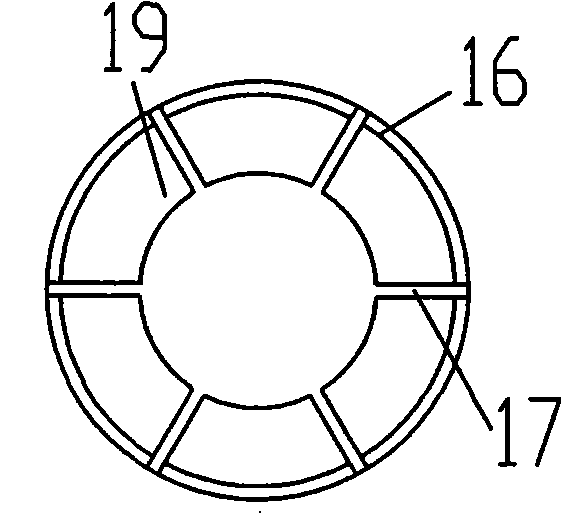

[0015] Such as figure 1 As shown, a belt roller 1 is respectively set on the left and right, wherein the belt roller on the right comprises a roller shaft 2, a cone core 8, and a matching taper sleeve 6 is arranged on the periphery of the cone core 8, and an elastic jacket 7 is arranged on the periphery of the cone sleeve 6, The cone core 8 is set on the periphery of the roller shaft 2, and the outer wall of the cone core 8 increases linearly from left to right, and the taper of the outer wall is 4-10 degrees, and the optimum value is 5 degrees. Taper sleeve 6 has a section of inner cavity which is a conical tube complementary to the outer wall of cone core 8, and its inner wall increases linearly from left to right. The tail end of the cone core 8 extends into the tapered tube to the left, and the outer periphery of the large end of the cone sleeve 6 is an elastic jacket 7 coaxial with the roller shaft 2. The right section of core is head end 15, and head end 15 periphery i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com