Insulation package reinforcement material buried in concrete and manufacturing process thereof

A manufacturing method and concrete technology, applied in the direction of building reinforcements, building structures, structural elements, etc., can solve the problems of reducing insulation performance, damaging the wrapping layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

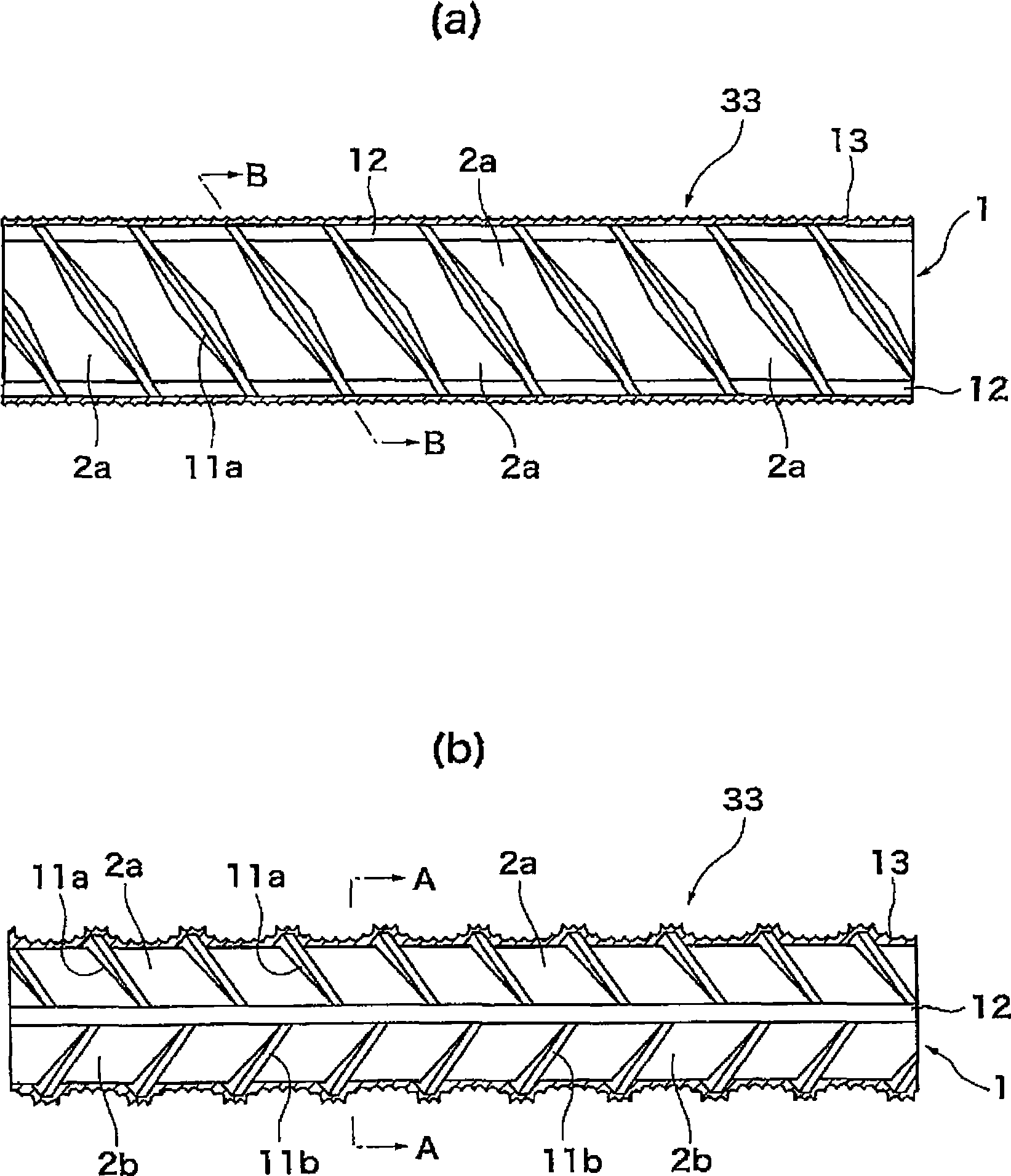

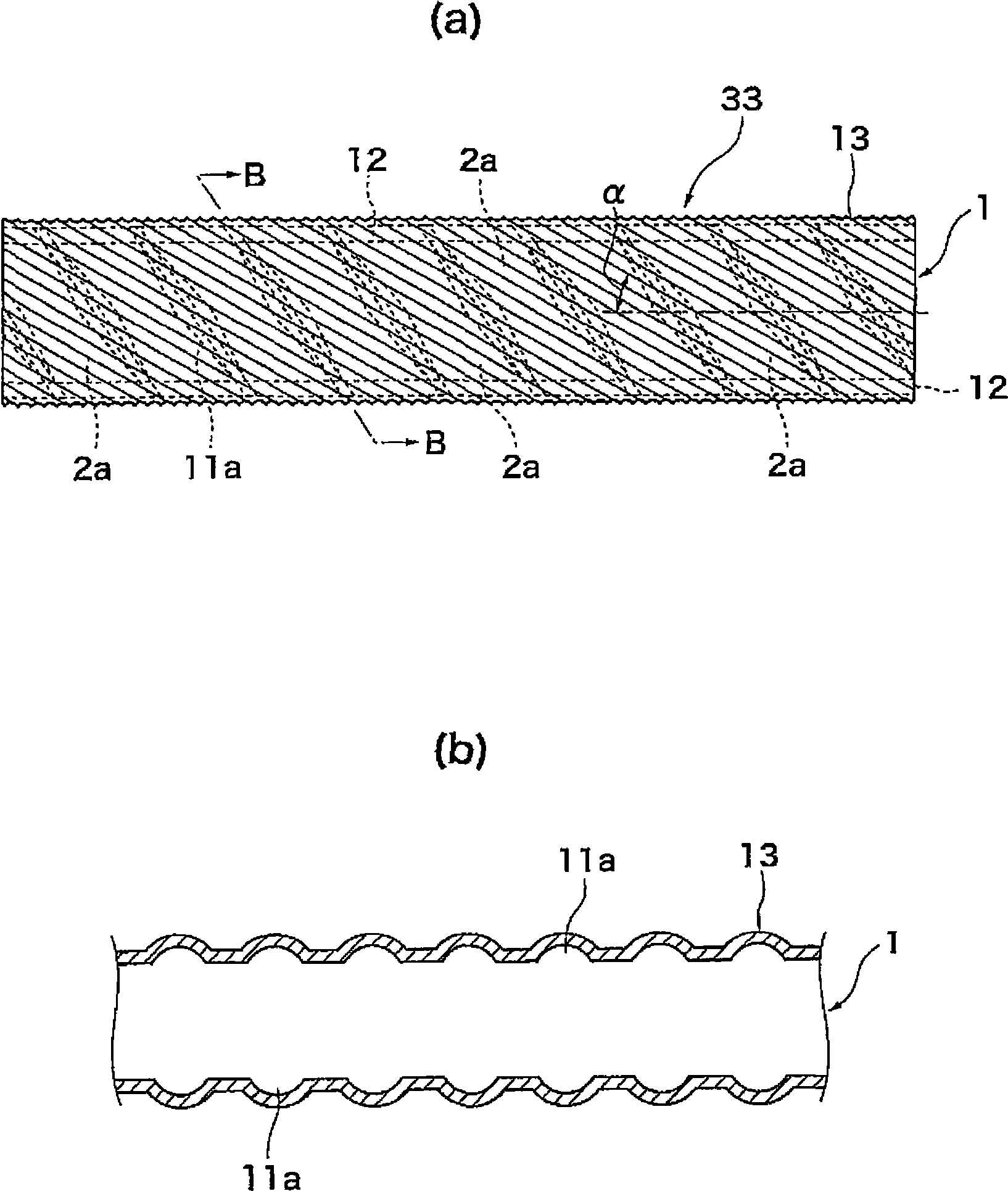

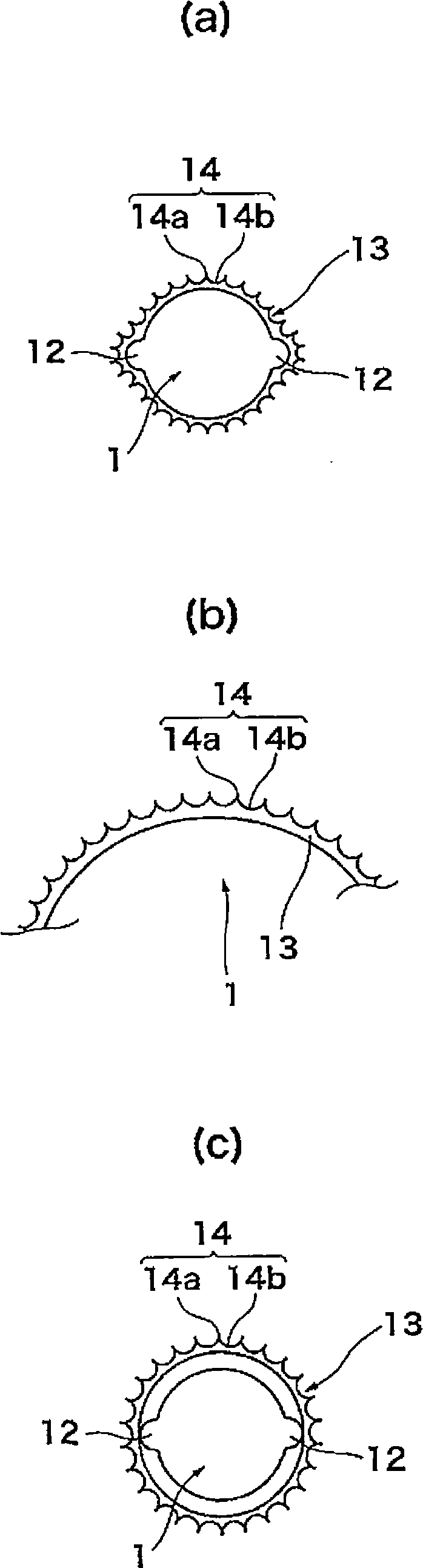

[0067] Next, see Figure 8 , to describe the method of using the electrically insulating and wrapped ribbed steel bar 33 manufactured by the above-mentioned manufacturing method for a track slab. in addition, Figure 8 , is a view showing a rail slab embedding the insulating sheathed steel material of the present invention using a ribbed steel bar, wherein (a) is a plan view, and (b) is a front view.

[0068] The concrete track slab 6 of illustrated embodiment, as Figure 8 As shown, it is a reinforced concrete slab with a length of 5m, a width of 2m, and a thickness of 0.19m. Two rails 7 , 8 are arranged symmetrically about the central axis in the concrete rail slab 6 . In addition, 17 in the figure is an embedded bolt (internal threaded part).

[0069] In order to withstand the load of the vehicle, the illustration is omitted, but in general, unwrapped ribbed steel bars are pre-embedded in the track slab as a reinforcing material for concrete. However, when a high-frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com