Fault diagnosis technology for mechanical tower

A fault diagnosis, mechanical tower technology, applied in the testing of machine/structural components, measuring vibration, measuring devices, etc., can solve the problem that it is difficult to propose design requirements and improvement suggestions, there is no safety detection device, and wind turbines are damaged by resonance during operation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

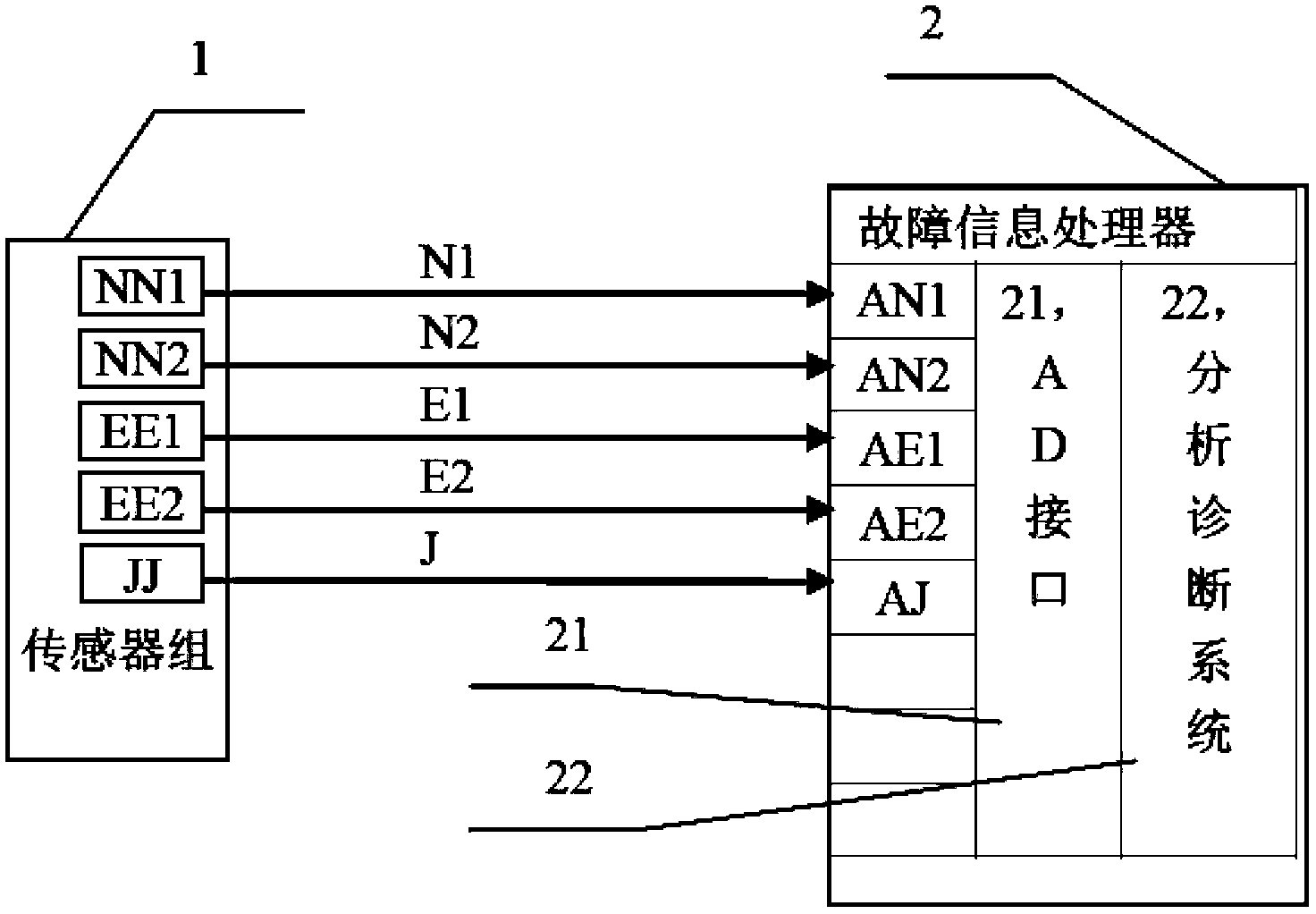

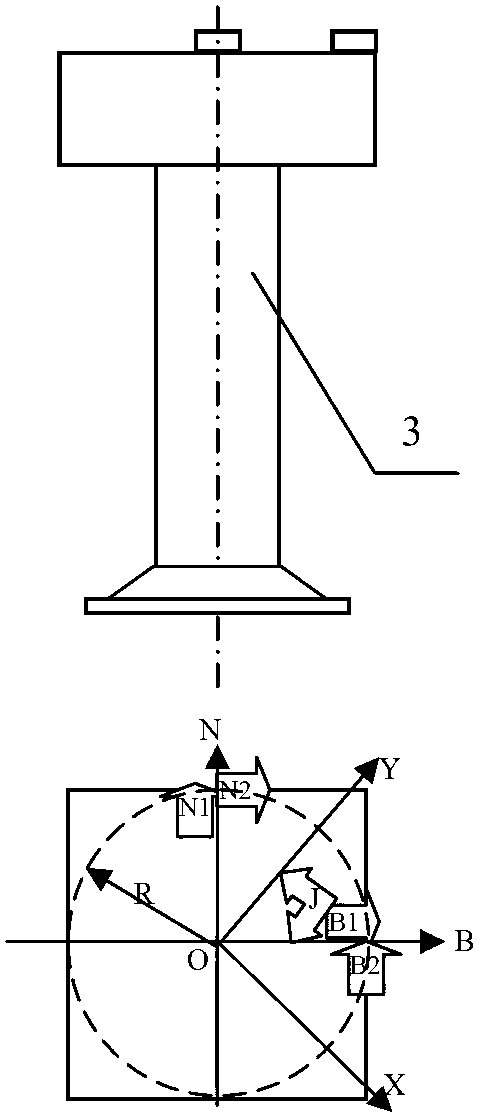

[0063] This mechanical tower fault diagnosis method includes a sensor group 1 and a fault information processor 2. The sensor group 1 includes an acceleration sensor NN1 installed on the upper layer of the tower and sensitive to the overall north-south direction of the tower according to geographic coordinates (east, south, northwest) and east-west Acceleration sensor EE1 for directional vibration, and acceleration sensor NN2, EE2 for torsional vibration of the sensitive tower around its symmetry center O, also includes polar coordinate sensor JJ for detecting the external Y direction relative to the east-west direction of the tower and taking the east as a reference; fault information Processor 2 includes AD interface 21 and analysis and diagnosis system (software) 22; sensor output acceleration signal N1, acceleration signal N2, acceleration signal E1, acceleration signal E2, and the polar coordinate angle J signal of the force direction are respectively connected to the fault...

Embodiment 2

[0105] Embodiment 2 is a tower center trajectory scheme that simplifies the fault information processor 2 or its AD interface 21 and analysis and diagnosis system 22 into an oscilloscope to directly observe the tower amplitude in real time.

[0106] It is characterized in that the fault information processor is partially replaced by an oscilloscope, and the signal lateral vibration e1 or acceleration signal E1 output by the separation operator 23 representing the east-west vibration of the tower is connected to the X axis of the oscilloscope, and the X axis represents the east; 23, the signal lateral vibration n1 or acceleration signal N1 outputted to represent the vibration of the tower in the north-south direction is connected to the Y axis of the oscilloscope, and the Y axis represents the north; when the tower vibrates, the oscilloscope draws the motion amplitude or quasi- acceleration trajectory. For example, it shows in time the dangerous condition of the tower resonance...

Embodiment 3

[0107] Embodiment 3, a tower fault diagnosis method, when the fault information processor is used to collect the acceleration signal N1, acceleration signal N2, acceleration signal E1, acceleration signal E2, polar coordinate angle J, lateral vibration n1, e1, torsional vibration signal in real time NZ, use the analysis and diagnosis system 22 to not only draw the tower center trajectory in real time, as shown in Figures 10-1 to 10-3, (wherein Figure 10-1 shows that the lateral vibration n1 is an N waveform, and the lateral vibration e1 is an E waveform, with an amplitude of 0.1 m and the frequency is the same, and the phase difference is 90 degrees. At this time, the tower center track is a circle with a diameter equal to 0.2m. Figure 10-2 shows that the lateral vibration n1 is an N waveform, and the lateral vibration e1 is an E waveform, with an amplitude of 0.1m. The north-south vibration frequency is three times that of the east-west vibration frequency. When excited by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com