Prismatic lens, prism device and backlight module thereof

A backlight module and prism sheet technology, applied in prisms, optics, optical components, etc., can solve the problems of small angle range and small system design flexibility, achieve a large design range and improve the effect of spot problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate a better understanding of the present invention, the following will describe it in detail in combination with preferred embodiments of the present invention.

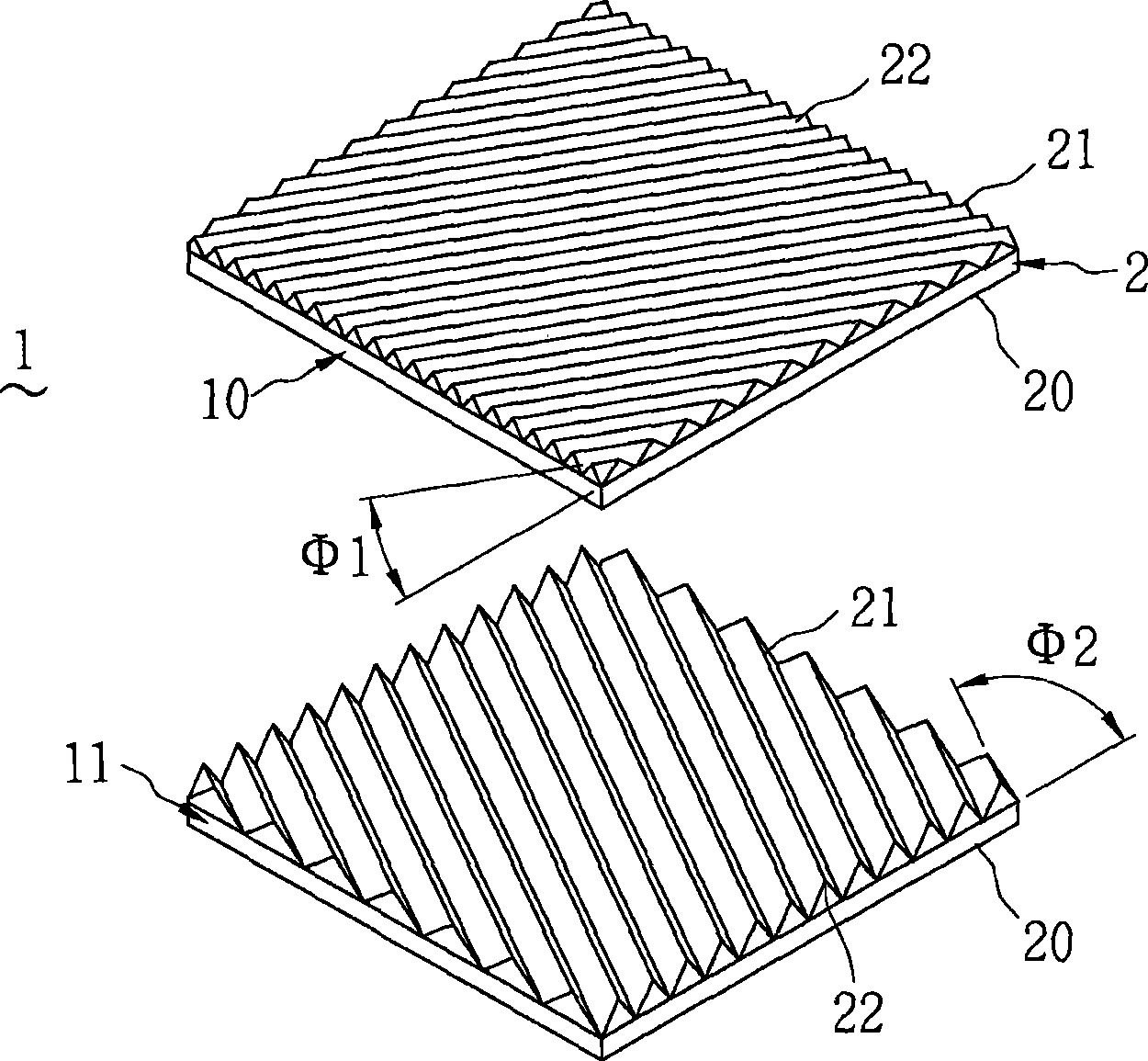

[0030] like image 3 As shown, the prism device 1 according to an embodiment of the present invention includes two oppositely arranged prism sheets 10 , 11 . Each prism sheet 10 , 11 has the same size and includes a rectangular transparent substrate 2 , and the substrate 2 has an incident surface 20 and an outgoing surface 21 opposite to each other. The material of the substrate 2 can be optical grade PET (polyester), COC (cyclic olefin copolymer), or TAC (triallyl cyanurate). The incident surface 20 has a smooth surface, and a plurality of parallel micro-triangular prisms 22 are arranged on the outgoing surface 21 . The micro-triangular prisms 22 are made by wet coating or embossing, and the included angles Φ1 and Φ2 between each micro-triangular prism 22 and the long side of the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com