Motor riveting structure

A motor and structure technology, applied in the field of riveting structure of motors, can solve the problems of wasting materials and man-hours, and achieve the effects of convenient production, avoiding waste of resources, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

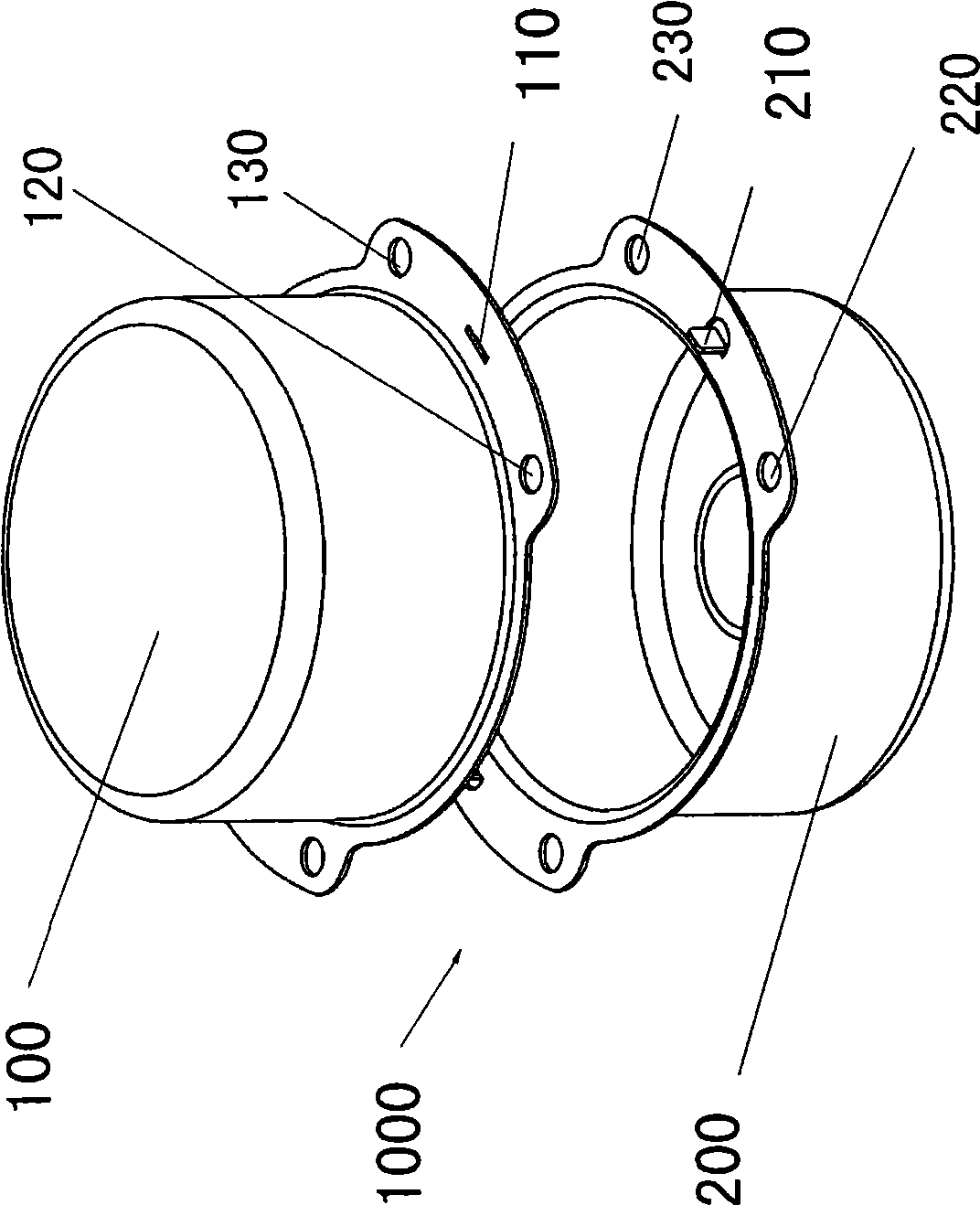

[0017] Such as Figure 2A , Figure 2B Shown is a schematic diagram of the first embodiment of the present invention. A slot 110 is provided on the side of the upper housing 100 of the motor, and a protrusion 210 is provided on the side of the lower housing 200, and the positions of the protrusion 210 and the slot 110 correspond to each other. When riveting the upper and lower shells, buckle the protrusions 210 into the grooves 110, then flatten the protrusions 210, make the protrusions 210 buckle the upper shell 100 of the motor after bending, thereby playing the role of riveting, and then use screws and nuts (Fig. (not shown in ) are respectively tightened and fixed on the screw holes 120, 220 and the screw holes 130, 230.

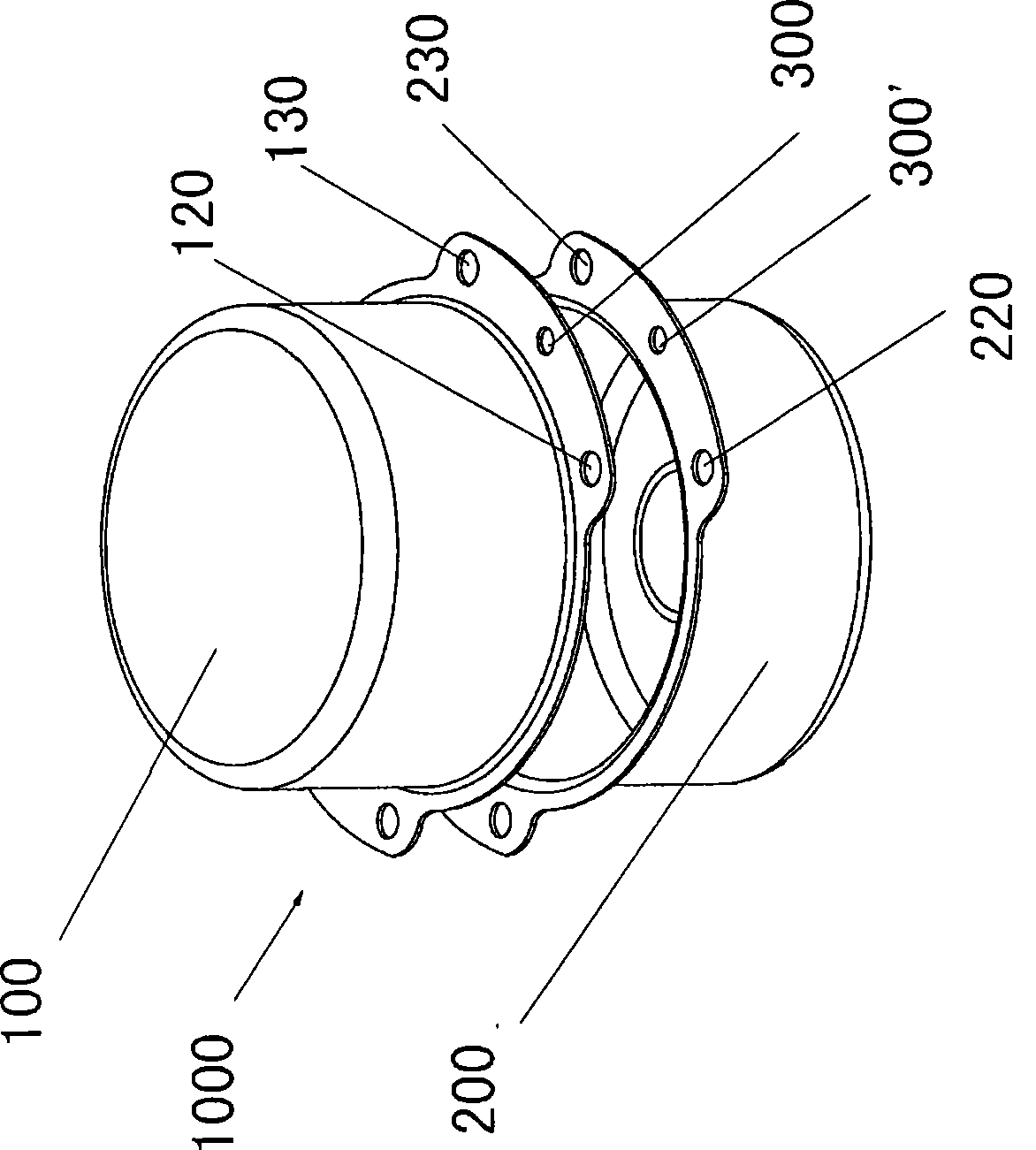

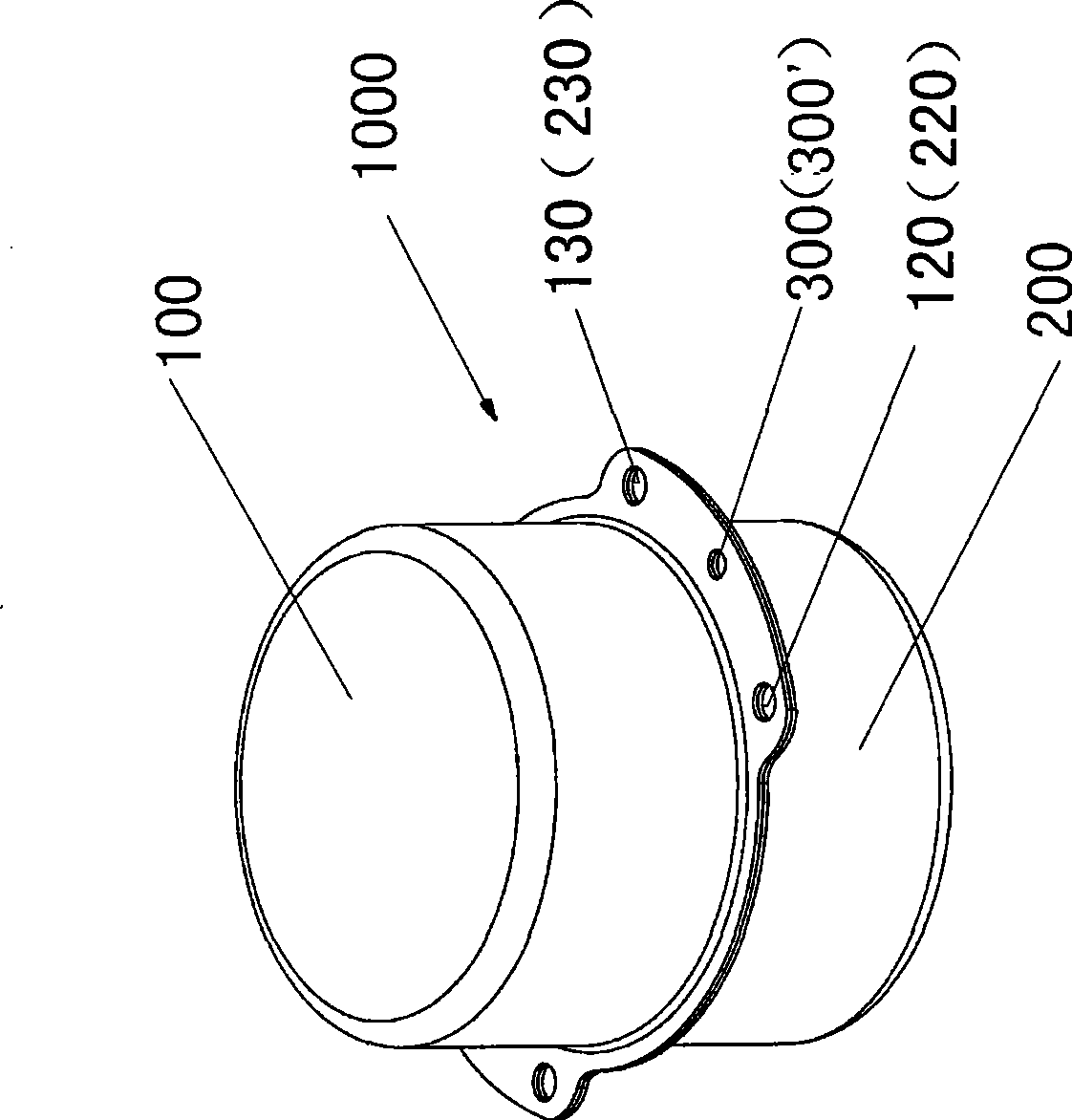

[0018] Such as Figure 3A , Figure 3B Shown is a schematic diagram of the second embodiment of the present invention. Cut off a small part of the side between the two screw holes 120, 130 on the side of the upper housing 100 of the motor, leaving a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap