A polishing disk with internal circulated cooling

A polishing disc and internal circulation technology, used in surface polishing machine tools, grinding/polishing equipment, abrasives, etc., can solve the problems of droplet splashing, inappropriate precision machining occasions, involving liquid collection, etc., to achieve easy layout , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

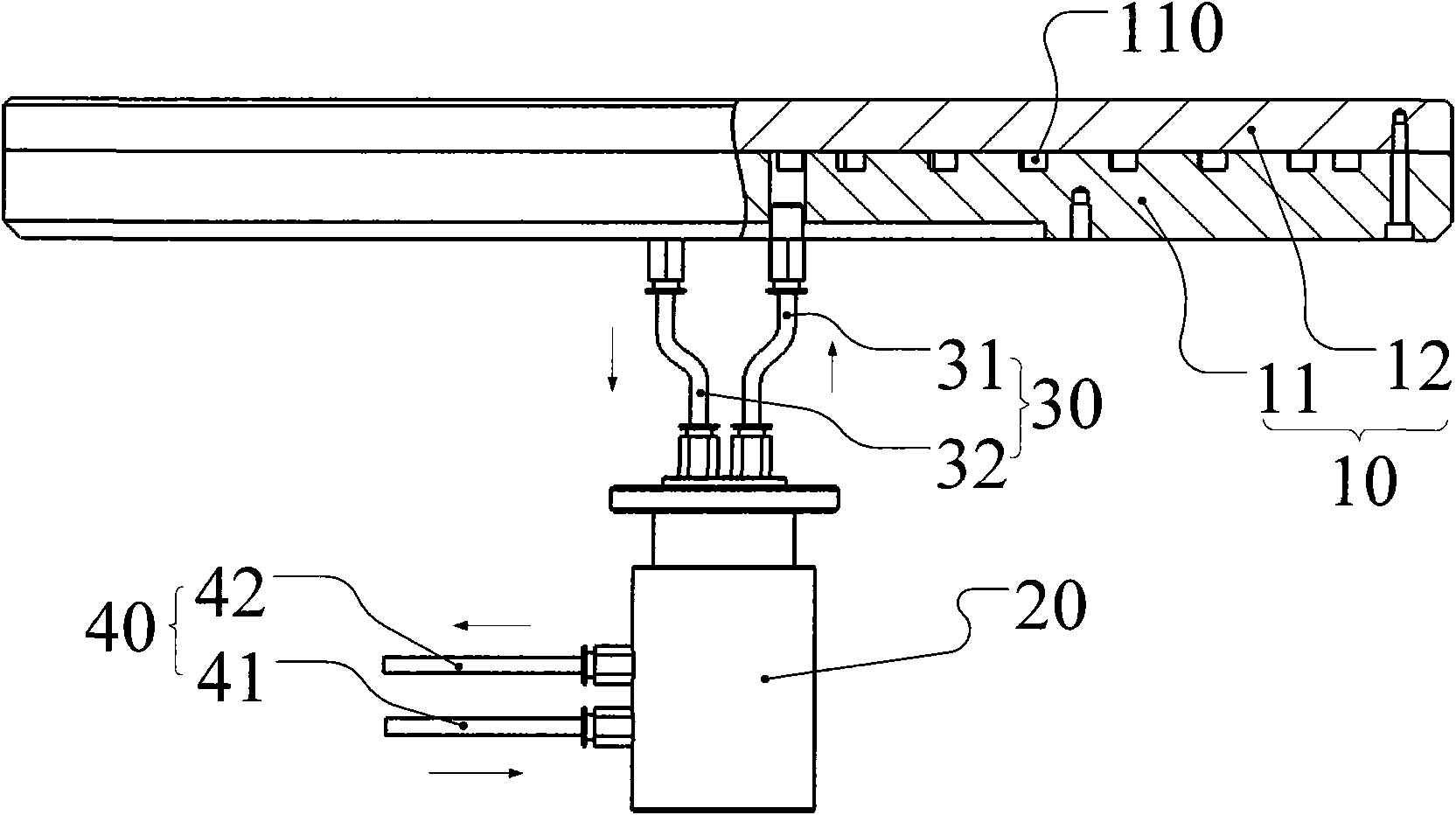

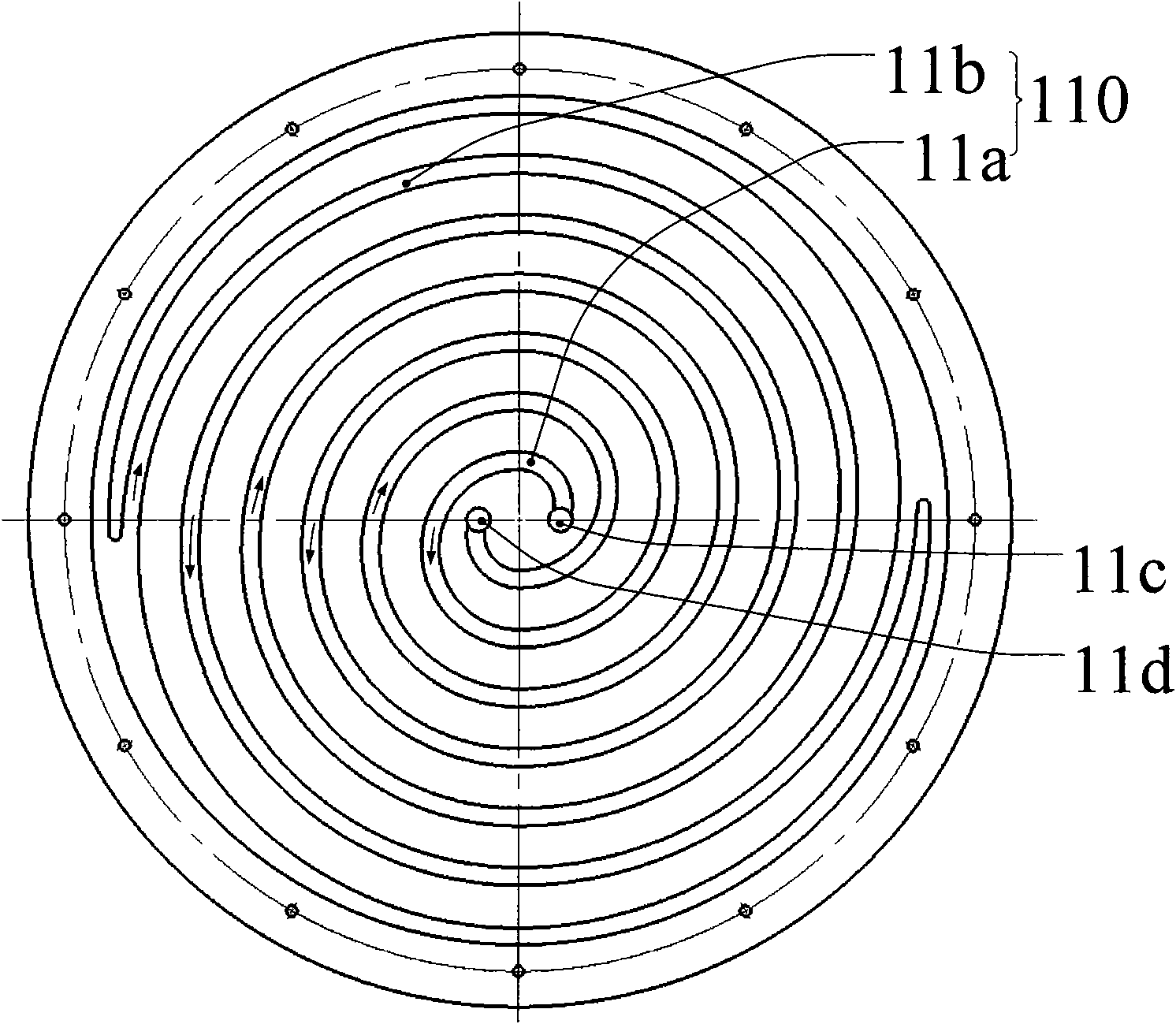

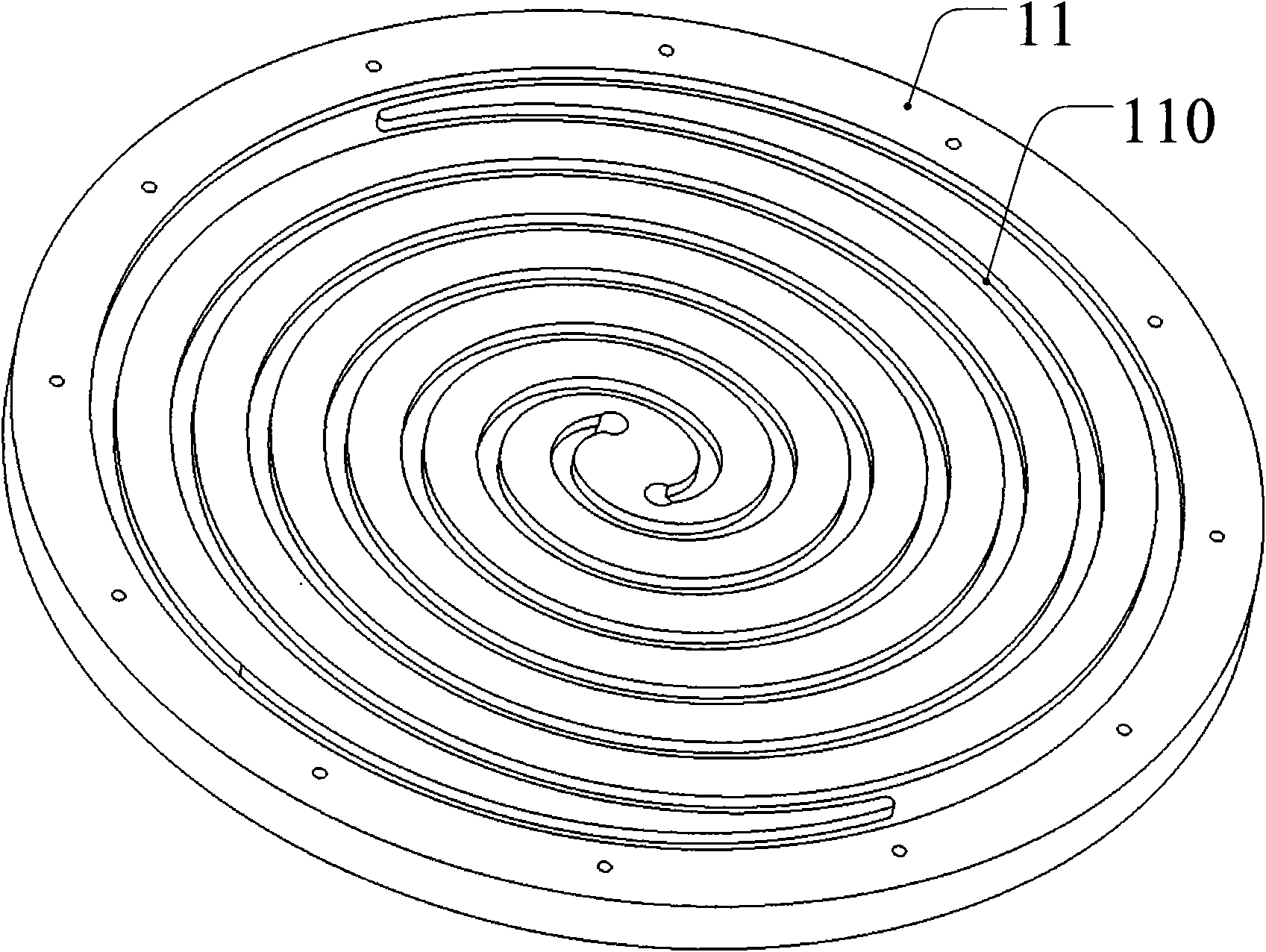

[0020] An internal circulation cooling polishing disc, such as figure 1 As shown, the internal circulation cooling polishing disc is mainly composed of a combined polishing disc 10, a rotary joint 20, an internal piping system 30 and an external piping system 40. The combined polishing disc 10 consists of an upper disc 12 and a lower disc 11 composition, the bottom plate 11 is provided with a spiral circulation groove 110 (such as image 3 as shown, image 3 is the three-dimensional diagram of the circulation groove of the bottom wall), including the liquid inlet spiral groove 11a and the liquid return spiral groove 11b, the liquid inlet spiral groove 11a and the liquid return spiral groove 11b are interlaced and symmetrical to the center, and the two spiral grooves The slots meet at the outermost ring (eg figure 2 as shown, figure 2 is the schematic diagram of the circulation groove of the lower wall), the starting point of the liquid inlet spiral groove 11a is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com