Outfield shape control forming device for laser online detection of the change of the polymer condensation state

A molding device and polymer technology, applied in the preparation of test samples, measurement of scattering properties, etc., can solve the problems of impossible polymer structure and performance, test performance, and cannot be used to truly characterize changes in polymer molding morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

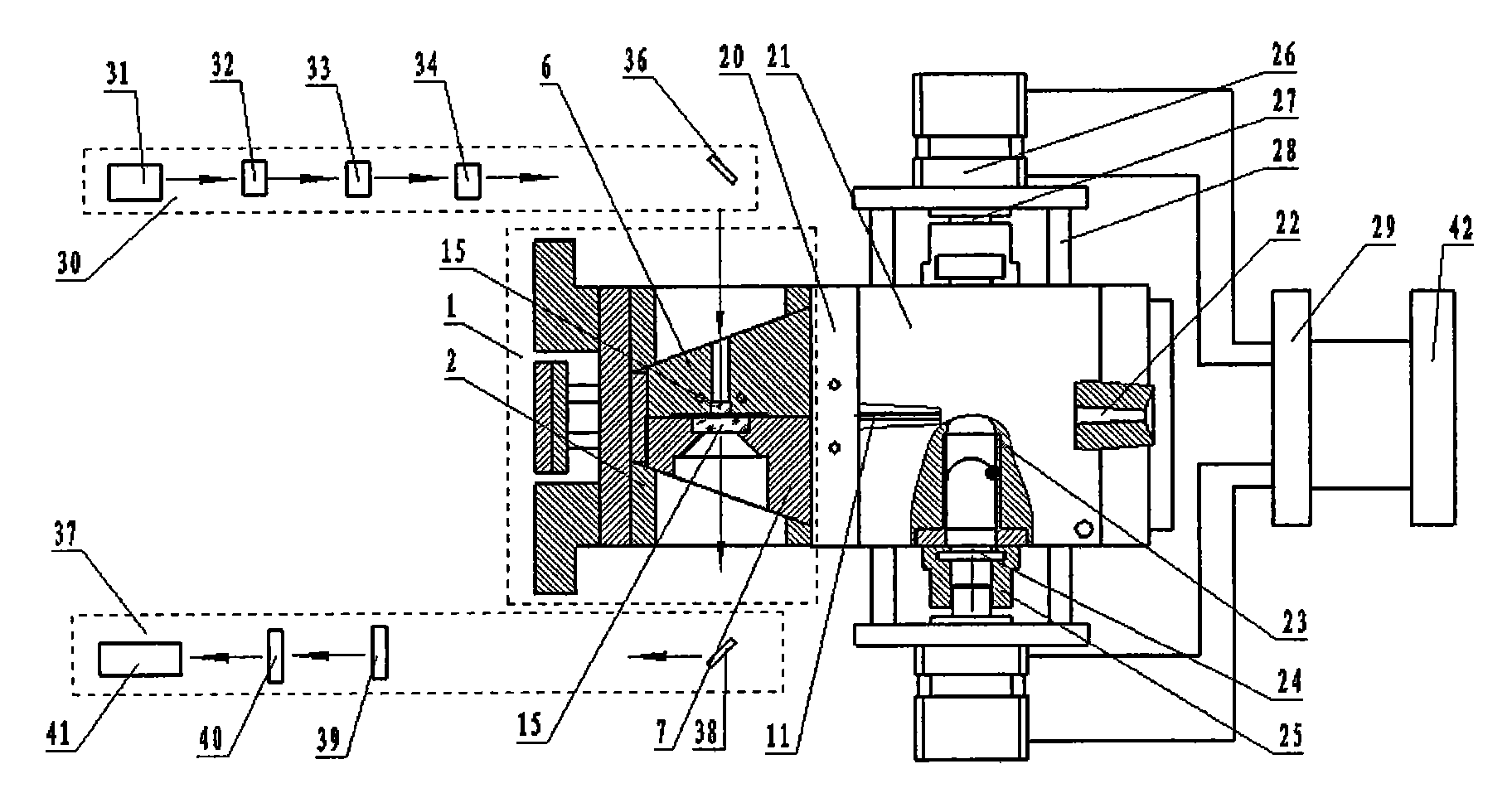

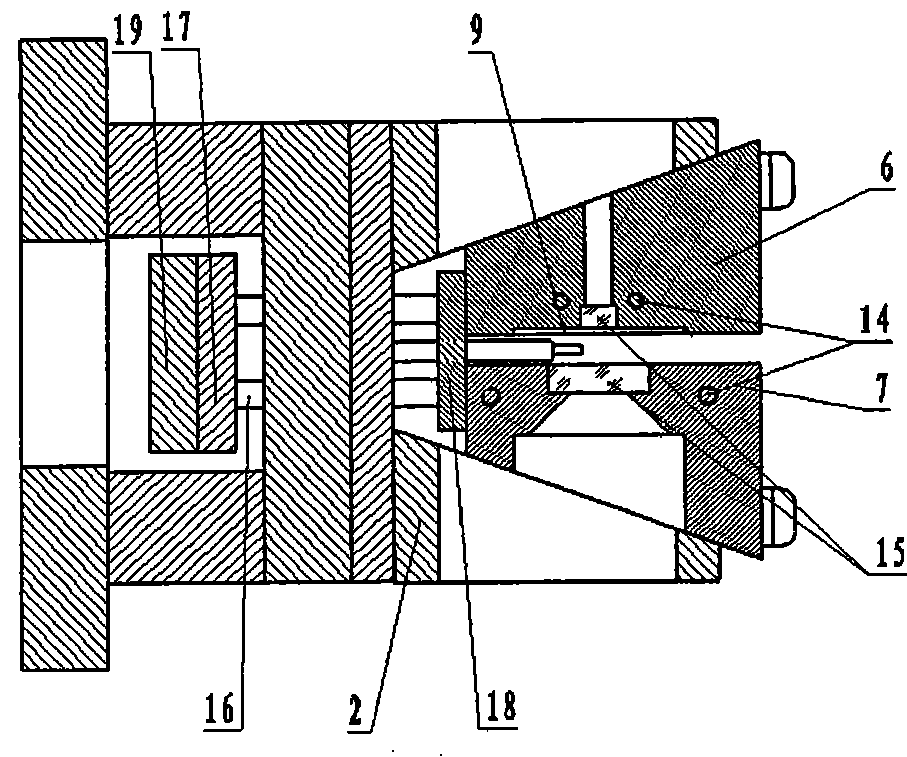

[0023] The external field shape control molding device for laser on-line detection of polymer condensed state changes given in this embodiment is composed of a dynamic pressure-holding injection mold, a laser detection system, a hydraulic system 29 and a computer control system 42 . Among them, the dynamic pressure-holding injection molding mold is composed of a movable mold 1, a fixed mold 20, a hot runner plate 21, and a hydraulic cylinder 26 connected to both sides of the hot runner plate 21 and a cylinder piston, and is installed on the injection molding machine. The mechanism 30 is installed on one side of the moving mold 1, and the receiving mechanism 37 is installed on the other side of the moving mold 1. The cavity of the moving mold 1 corresponding to the laser detection system is light-transmitting, and the hydraulic system 29 and the hot runner plate 21 are on both sides. The hydraulic cylinder 26 is connected, and the computer control system 42 is connected with the...

Embodiment 2

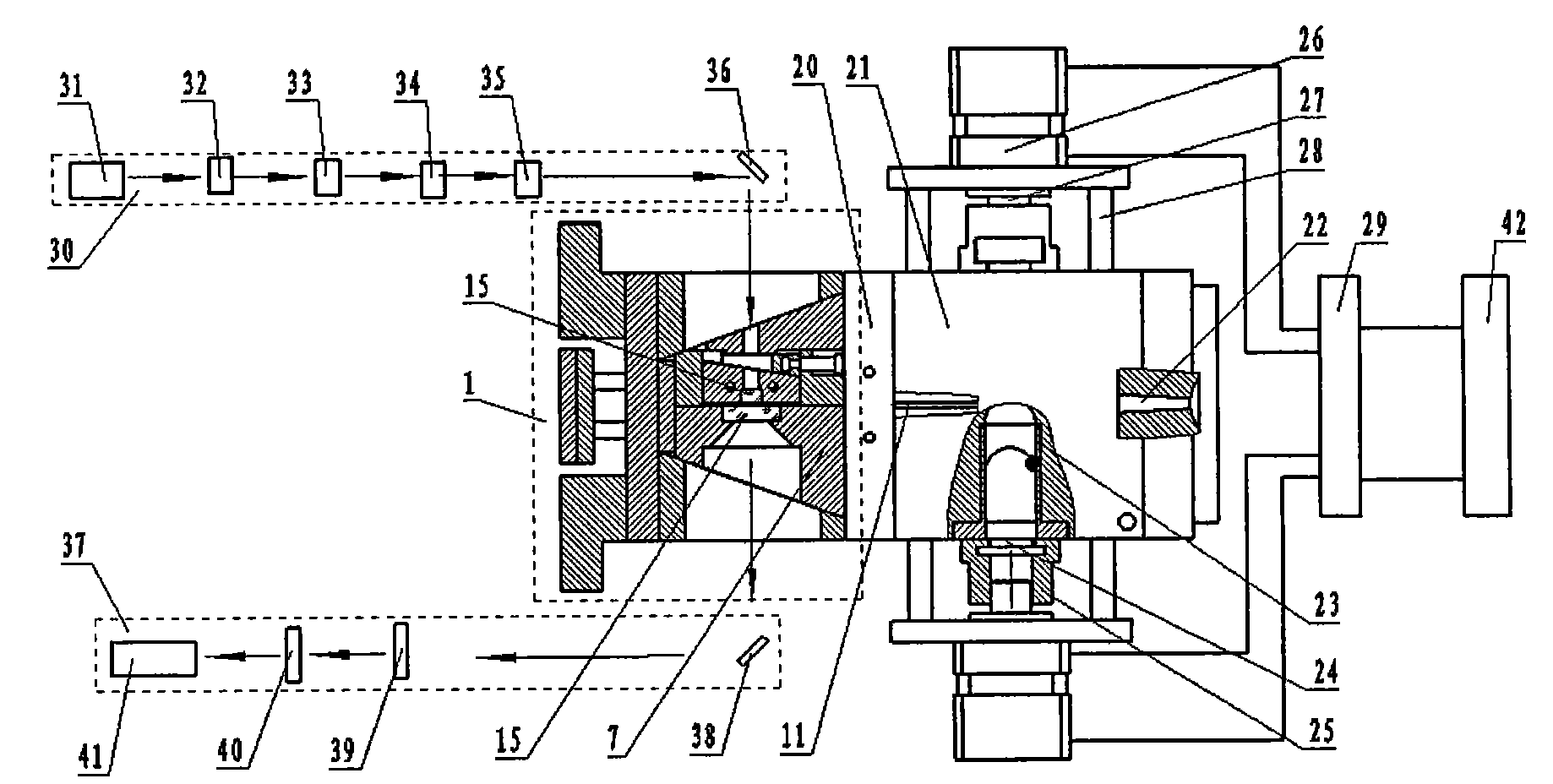

[0030] The external field shape control molding device for laser on-line detection of polymer condensed state changes given in this embodiment is also composed of a dynamic pressure-holding injection mold, a laser detection system, a hydraulic system 29 and a computer control system 42 . Among them, the dynamic pressure-holding injection molding mold is composed of a movable mold 1, a fixed mold 20, a hot runner plate 21, and a hydraulic cylinder 26 connected to both sides of the hot runner plate 21 and a cylinder piston, and is installed on the injection molding machine. The mechanism 30 is installed on one side of the moving mold 1, and the receiving mechanism 37 is installed on the other side of the moving mold 1. The part of the moving mold cavity 9 corresponding to the laser detection system is light-transmitting, and the hydraulic system 29 and the sides of the hot runner plate 21 The hydraulic oil cylinder 26 links to each other, and the computer control system 42 links ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com