System for realizing direct stopping of elevator and control method thereof

A control method and elevator technology, applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of low elevator operation efficiency, elevator emergency stop and slow speed crawling time, etc., to save manpower and improve operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

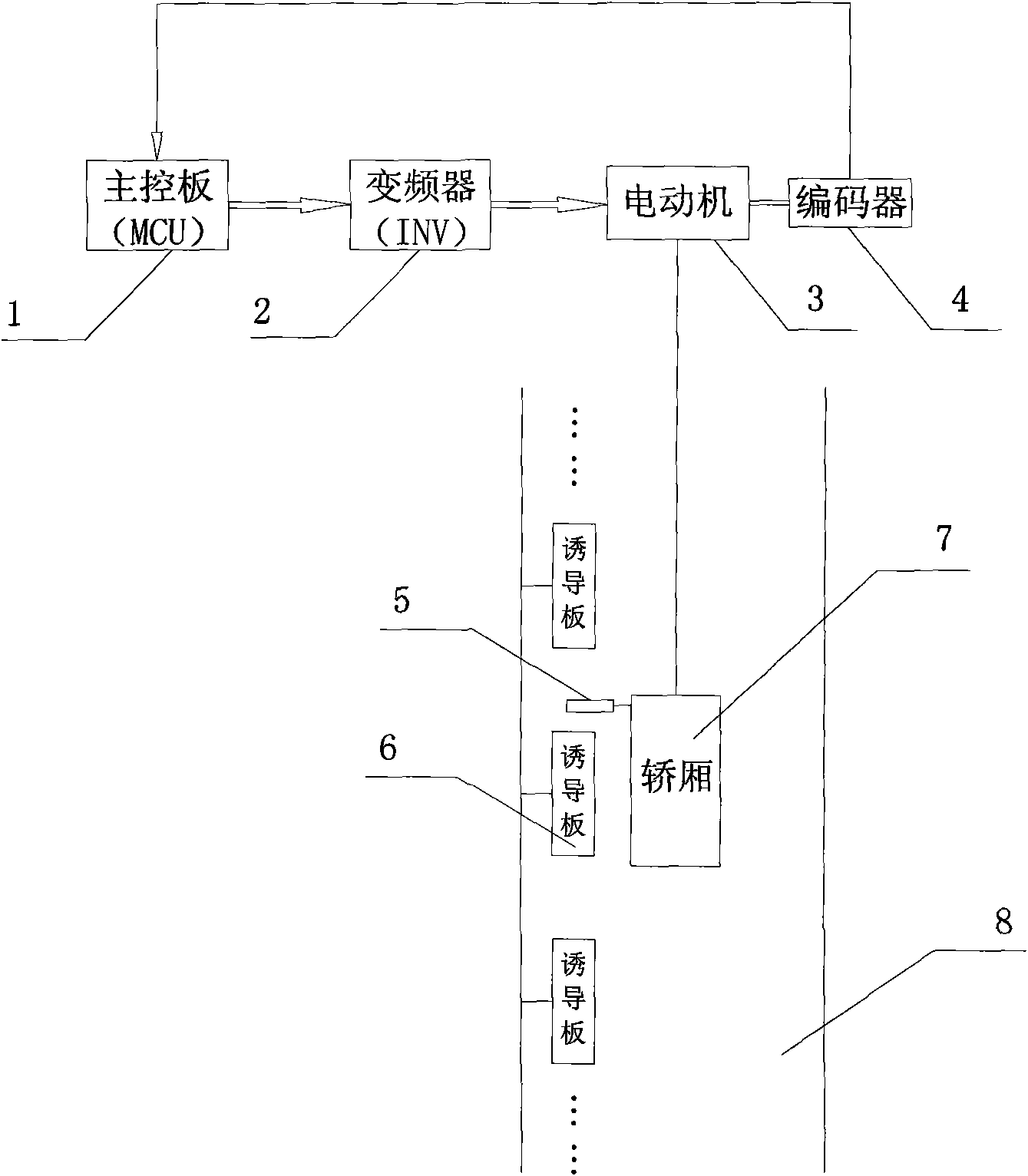

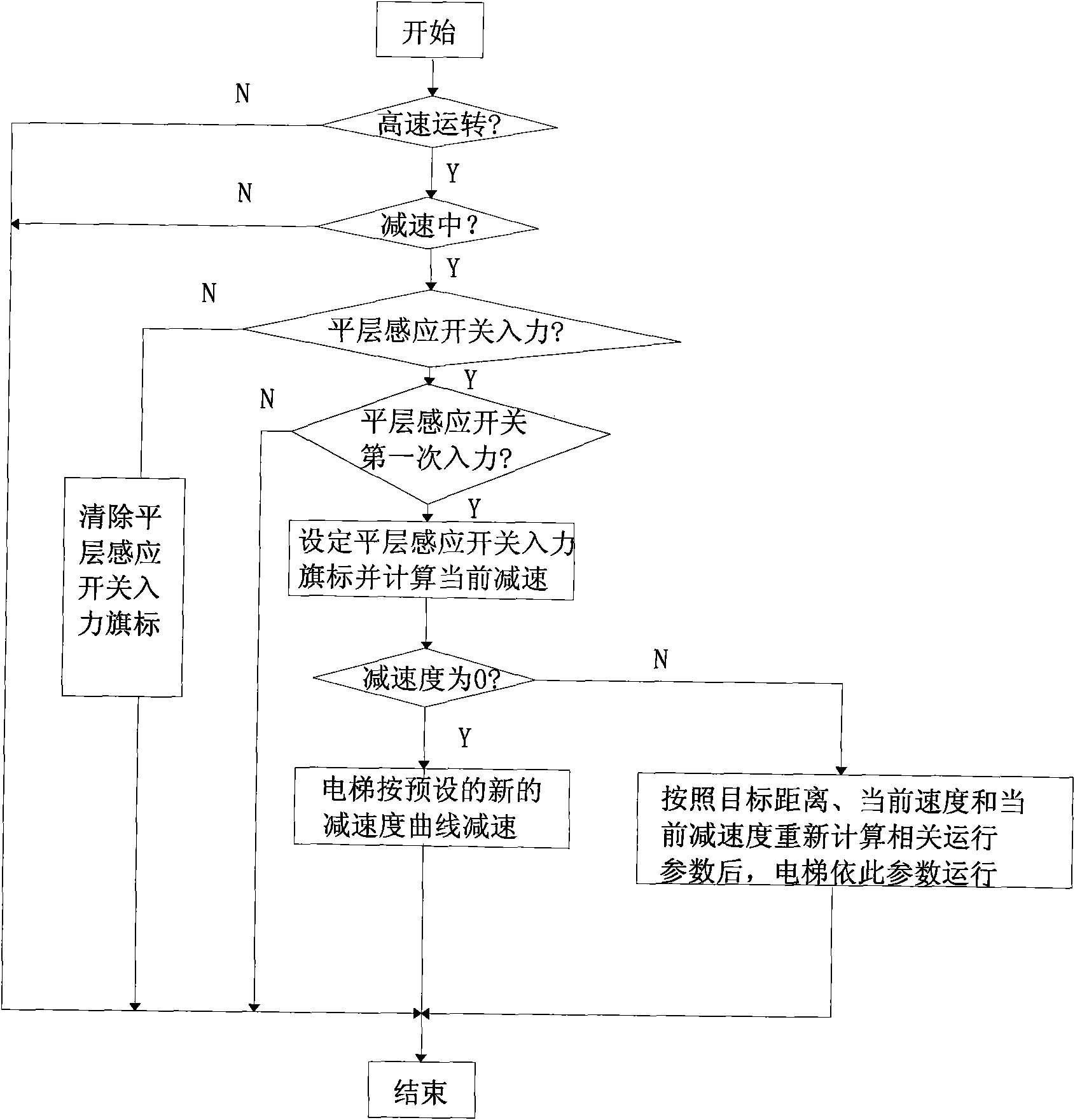

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. figure 1 It is a schematic diagram of the elevator system and its control method of the present invention, figure 2 It is a brief processing flow chart when entering the leveling sensor switch of the present invention. The present invention includes a main control board 1, a frequency converter 2, a motor 3, an encoder 4, a leveling sensor switch 5, an induction plate 6, a car 7, and a hoistway 8. The leveling sensor switch 5 is installed on the side wall of the car 7, the induction plate 6 is fixed at each floor position on the side wall of the hoistway 8, and is installed between the motor 3 and the car 7. The traction sheave and the wire rope drag the car 7 to run up and down, and the main control board 1 obtains the exact position of each floor station and the absolute position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com