Raising mechanism of slip form and steel framework

A technology of steel frame and sliding form, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of difficulty in ensuring the accuracy of steel components and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

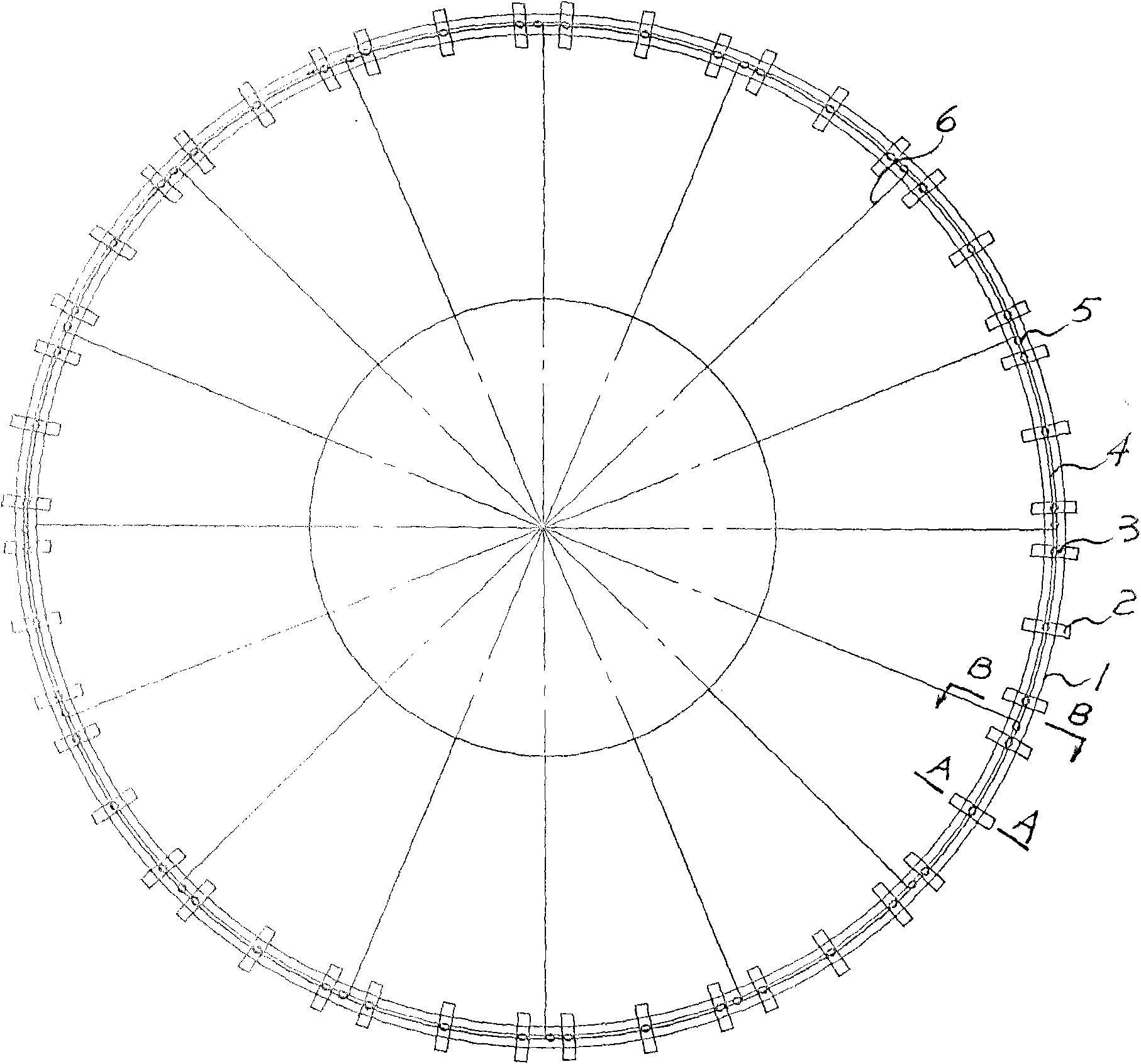

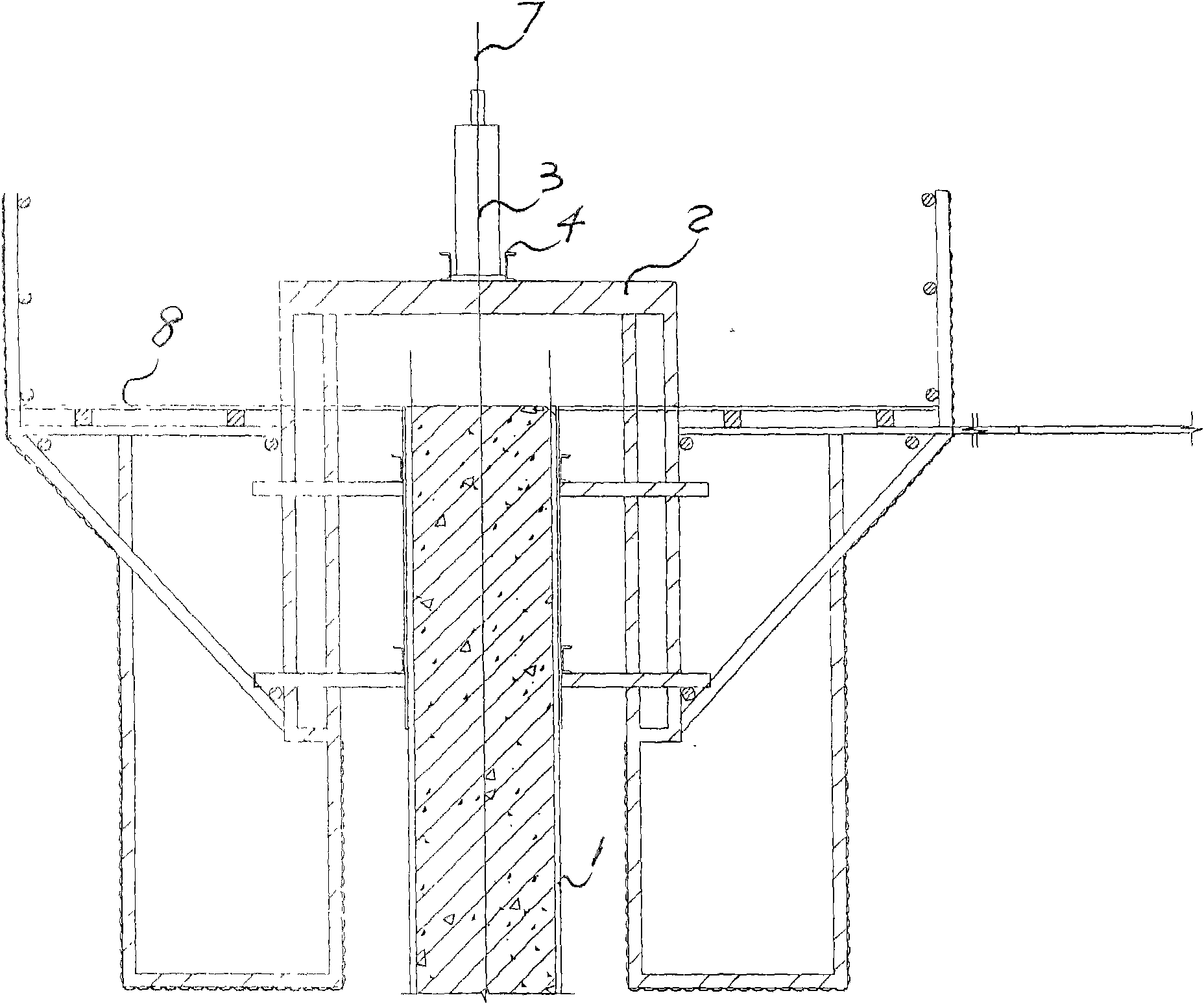

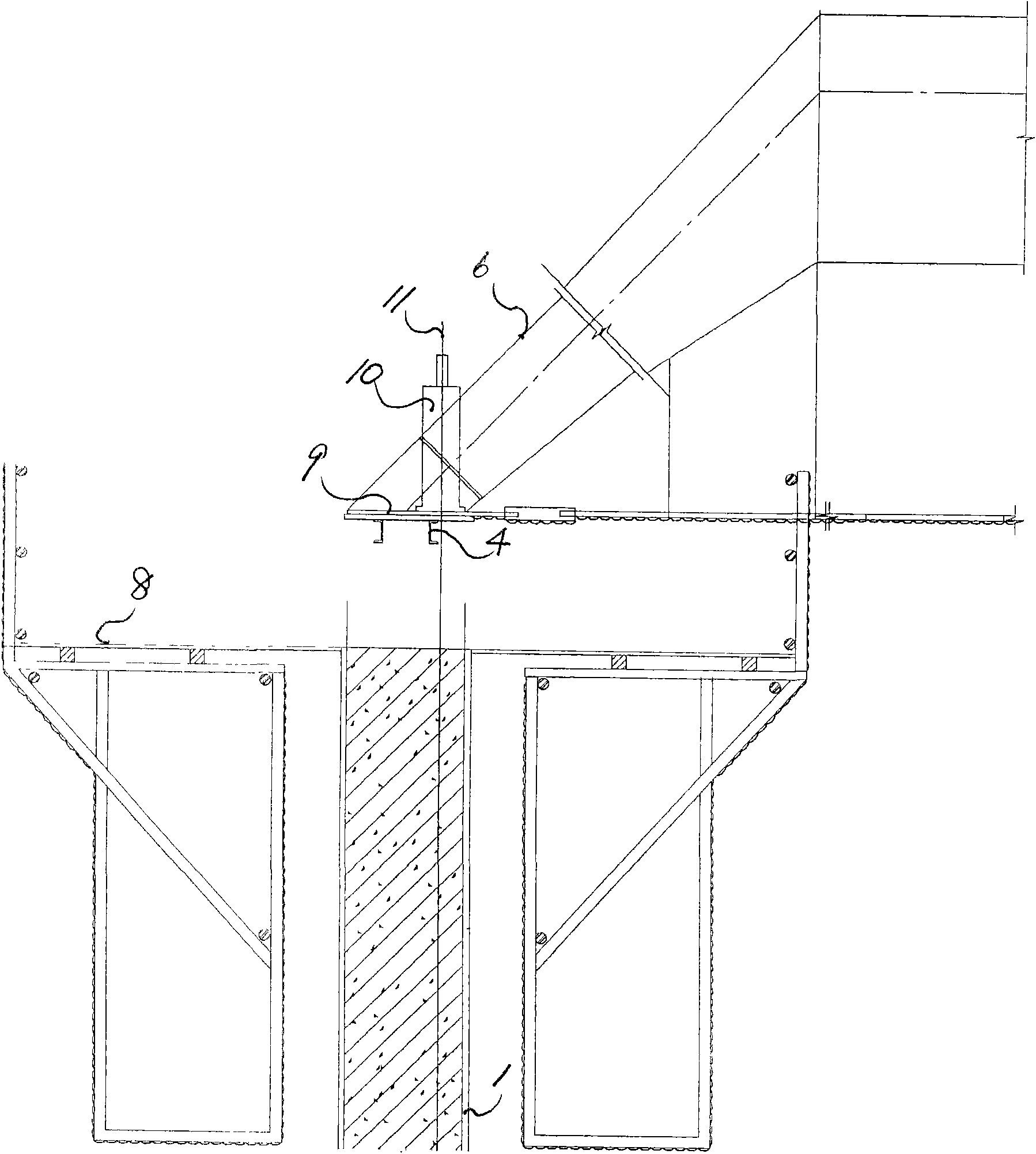

[0005] The present invention will be further described in conjunction with the above accompanying drawings. In the construction of existing concrete silos, the mechanism of gantry, hydraulic jack, and climbing pole is used. , to carry out the last section of cylinder pouring. The portal frame 2 is connected with the sliding form 1, and for the construction of pouring concrete and binding steel bars, a construction support platform 8 is set on the portal frame (see figure 2 ). The hydraulic jack used by this sliding form lifting mechanism has the function of rising along the climbing rod 7. This hydraulic jack can be selected from the hydraulic jack manufactured by Jiangdu Baisheng Sliding Form Complete Equipment Factory. The bottom of this jack is connected with the door frame. During the construction of the current silo, the materials used for the steel frame are sent to the top of the silo by a hoist for assembly and welding. This construction method has the disadvantages ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap