A thrust angular contact ball bearing

A contact ball, thrust angle technology, applied in the direction of ball bearings, bearing components, shafts and bearings, can solve the problems of inconvenient installation, difficult packaging and installation, grease leakage, etc., to achieve convenient transportation and installation, simple structure, Easy to assemble effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

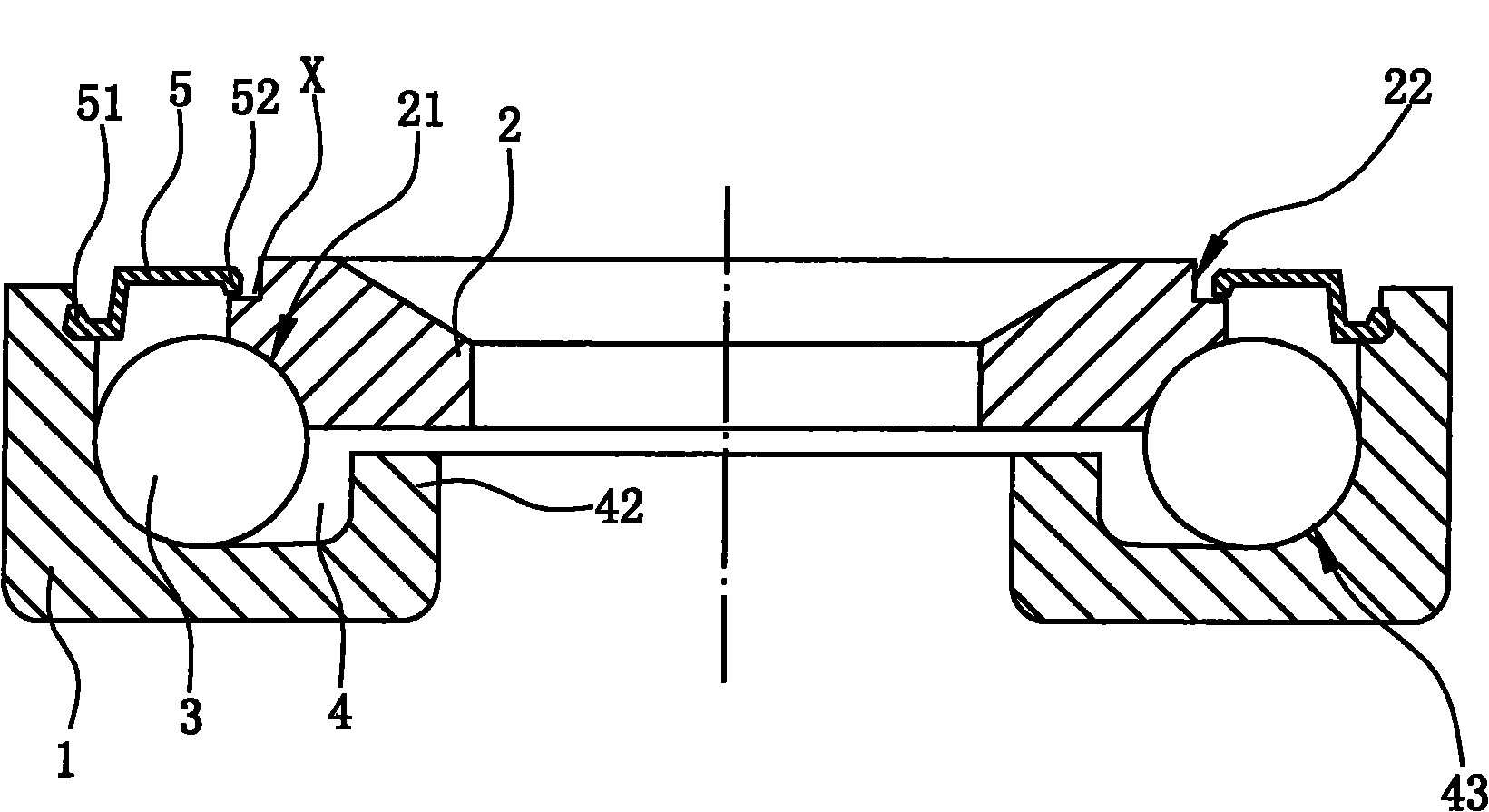

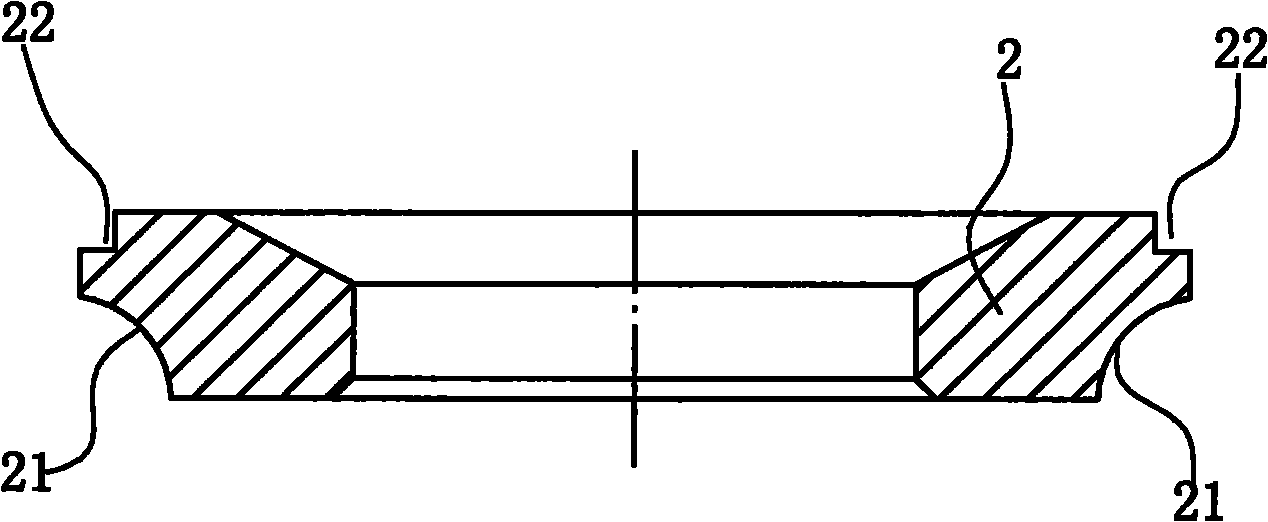

[0030] Figures 1 to 5 show the first embodiment of the present invention.

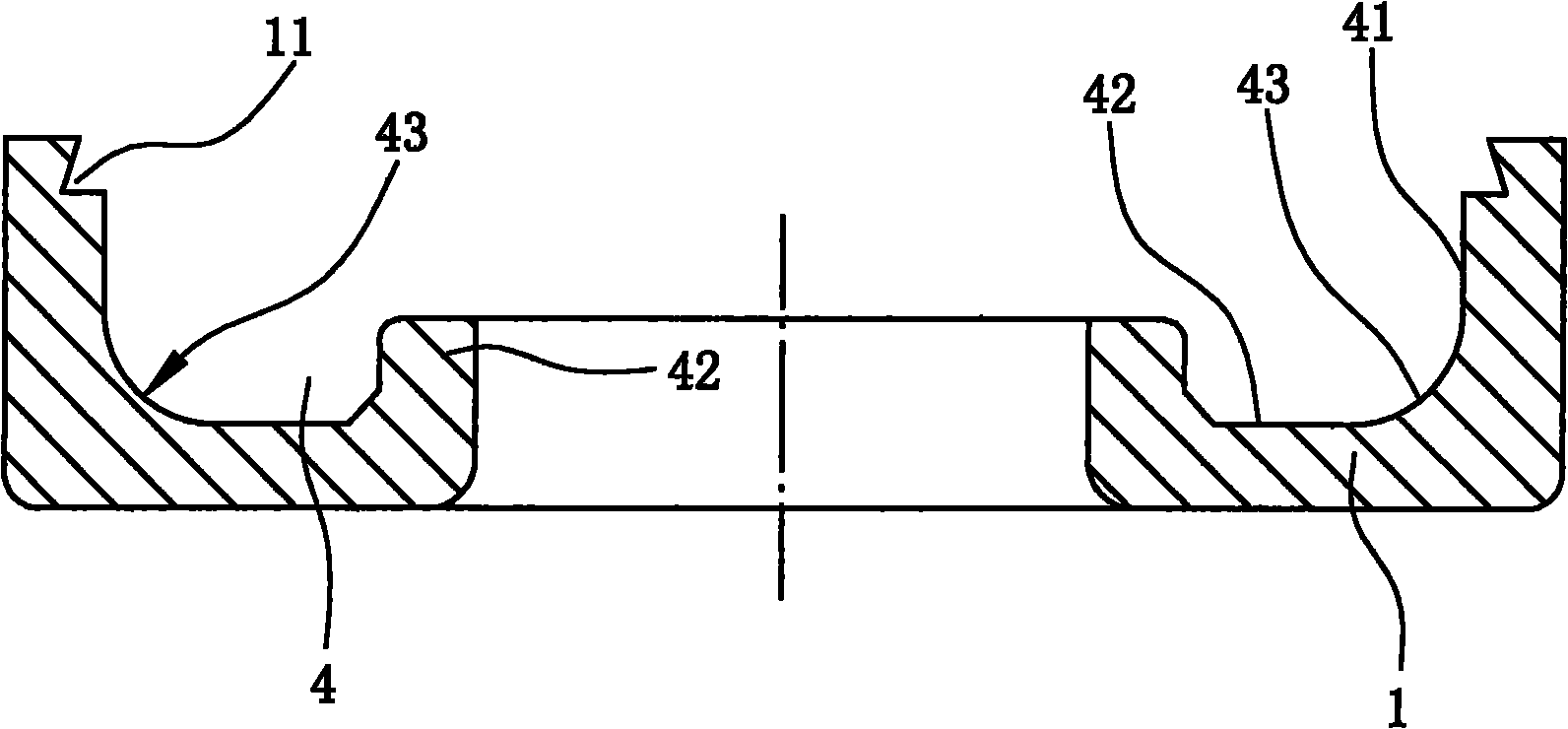

[0031] A thrust angular contact ball bearing includes a seat ring 1, a shaft ring 2 and steel balls 3. The cross-sectional shapes of the seat ring 1 and the shaft ring 2 are roughly ring-shaped.

[0032] There is an annular raceway 4 inside the seat ring 1, and the inner side of the annular raceway 4 has an upwardly extending annular rib 8, so that the cross section of the annular raceway 4 looks roughly U-shaped, and the inner surface 41 of the annular raceway 4 and The joint surface 43 between the bottom surfaces 42 is a concave arc surface attached to the outer surface of the steel ball 3 .

[0033] The steel ball 3 is placed in the ring raceway 4 and can roll in the ring raceway 4 , and at the same time, the lower outer surface of the steel ball 3 is attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com