Full circle-telescopic shafting end surface sealing device used for deep-sea platform

A technology of end face sealing and full rotation, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of long maintenance cycle, high working reliability, poor strength, and short wear-resistant life of deep sea offshore operation platforms, and achieve The effect of reducing the amount of water leakage, improving reliability and service life, and reliable water sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

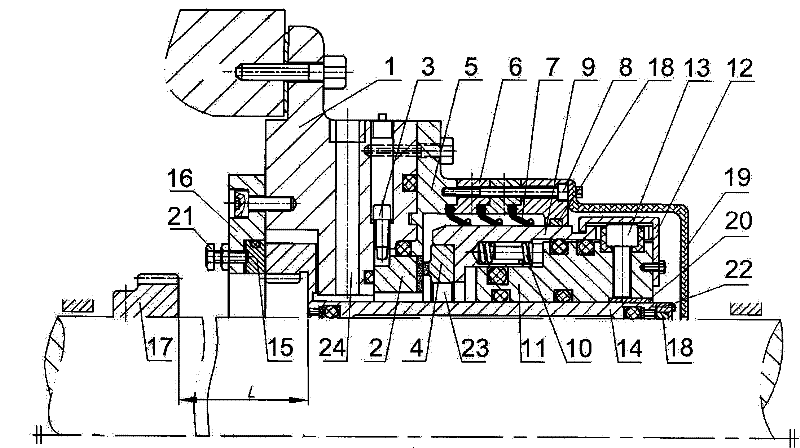

[0032] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0033] as attached figure 1 As shown, the present invention consists of a mounting base 1, a static sealing ring 2, a positioning screw 3, a dynamic sealing ring 4, a skeleton oil seal base 5, a fixed clamp ring 6, a skeleton oil seal 7, bolts 8, a moving ring bracket 9, and a post spring 10 , transmission snap ring 11, adjustment buckle 12, set screw 13, transmission sleeve 14, seal adjustment ring 15, pressure plate 16, main transmission ring 17, sand filter ring 18, protective cover 19, gasket 20, adjustment screw 21, Parts such as the flange cover 22 and some ○-shaped rubber sealing rings are assembled through threaded fasteners.

[0034] The invention is installed on the side of the bulkhead of each propulsion shaft of the deep sea water working platform near the sea water. Regardless of whether the propulsion shaft is running or telescopically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com