Temperature control method for projection objective of photoetching machine

A temperature control method and technology of projection objective lens, which are applied in the direction of using electric method for temperature control, electrical program control, microlithography exposure equipment, etc., can solve the problems of increasing system stabilization time and long search process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

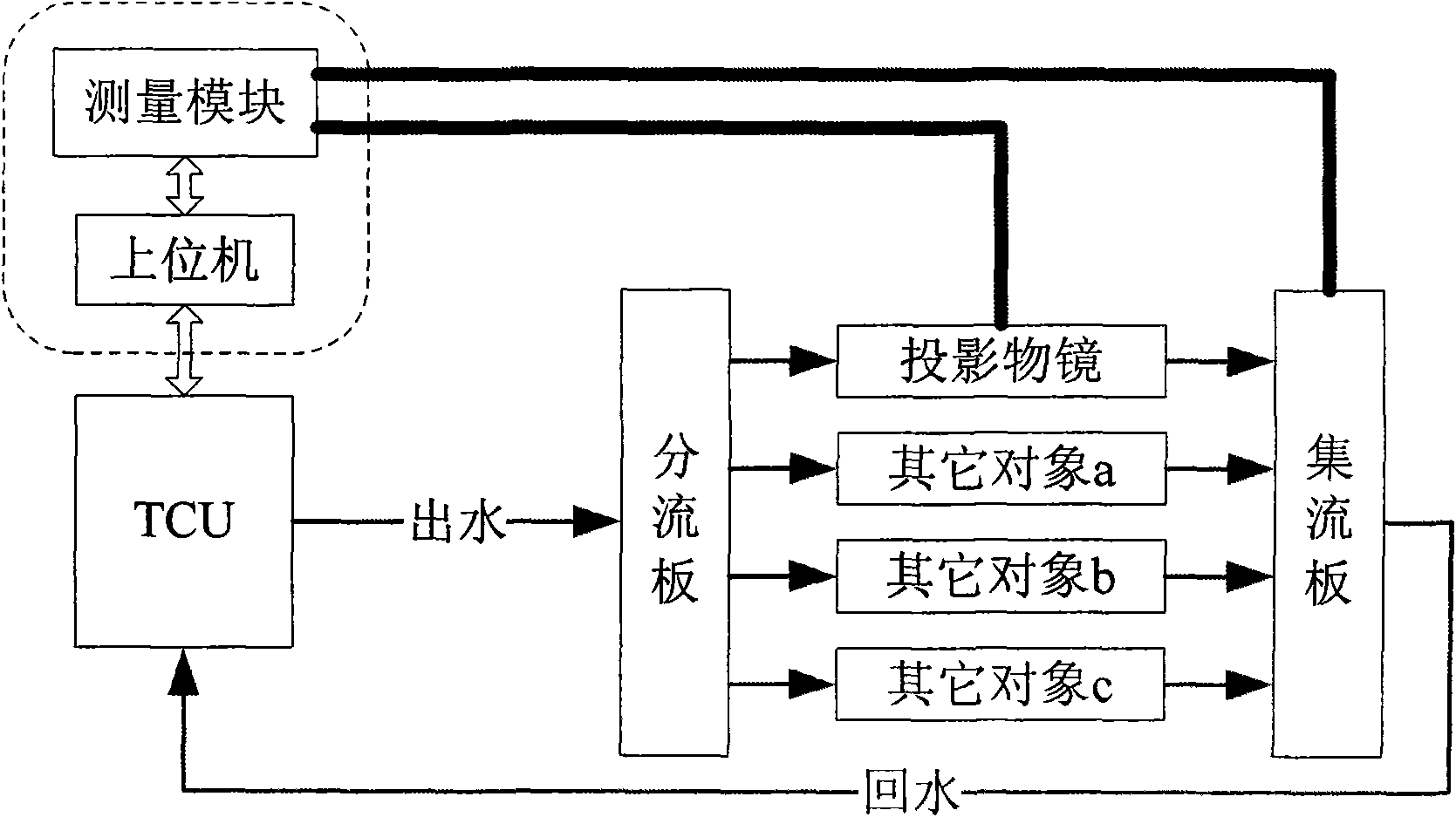

[0042] Such as figure 1 In the objective lens temperature control system shown, the TCU receives the set value sent by the controller module, and controls the internal heater and refrigerator according to a certain algorithm, thereby controlling the temperature of the circulating fluid to be close to the set value. The circulating fluid provided by the TCU is divided into multiple branches through the shunt, flows through the projection objective lens and other object components, and finally is combined by the current collector to flow back to the TCU.

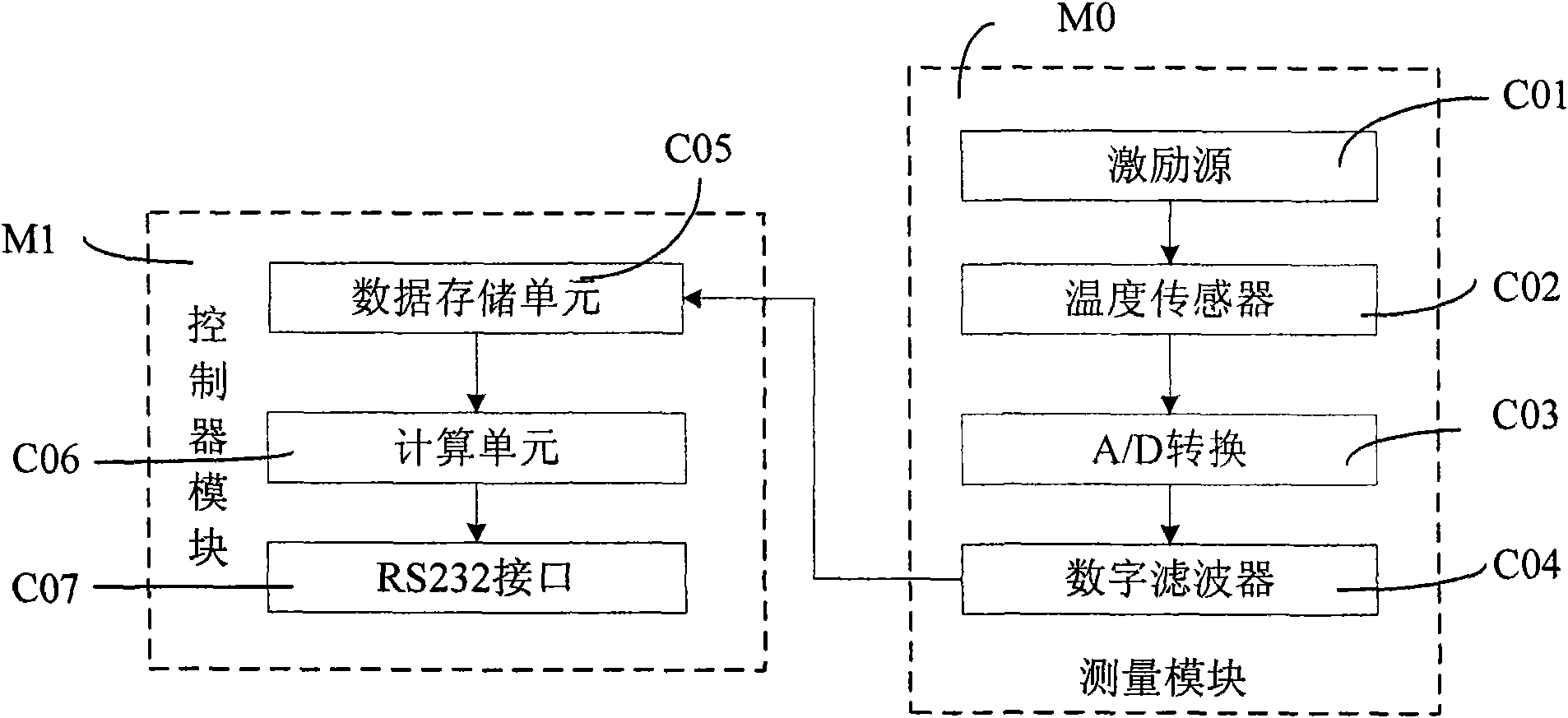

[0043] The invention provides a temperature control device, which mainly includes a measurement module M0 and a controller module M1.

[0044] Such as figure 2 As shown, the present invention provides a temperature control device for sending commands to the TCU, which includes a temperature measurement module M0 and a controller module M1, and the temperature measurement module M0 includes an excitation source C01, a sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com