Installation method for rubber intermediate head of high voltage power cable and device

An intermediate joint, high-voltage power technology, used in cable installation devices, cable joints, cable installation and other directions, can solve the problems of difficult cable installation, time-consuming and laborious, and large contact surface between the joint cavity and the cable, saving time for installation. Effort-saving, simple and reliable operation, and shortened set-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

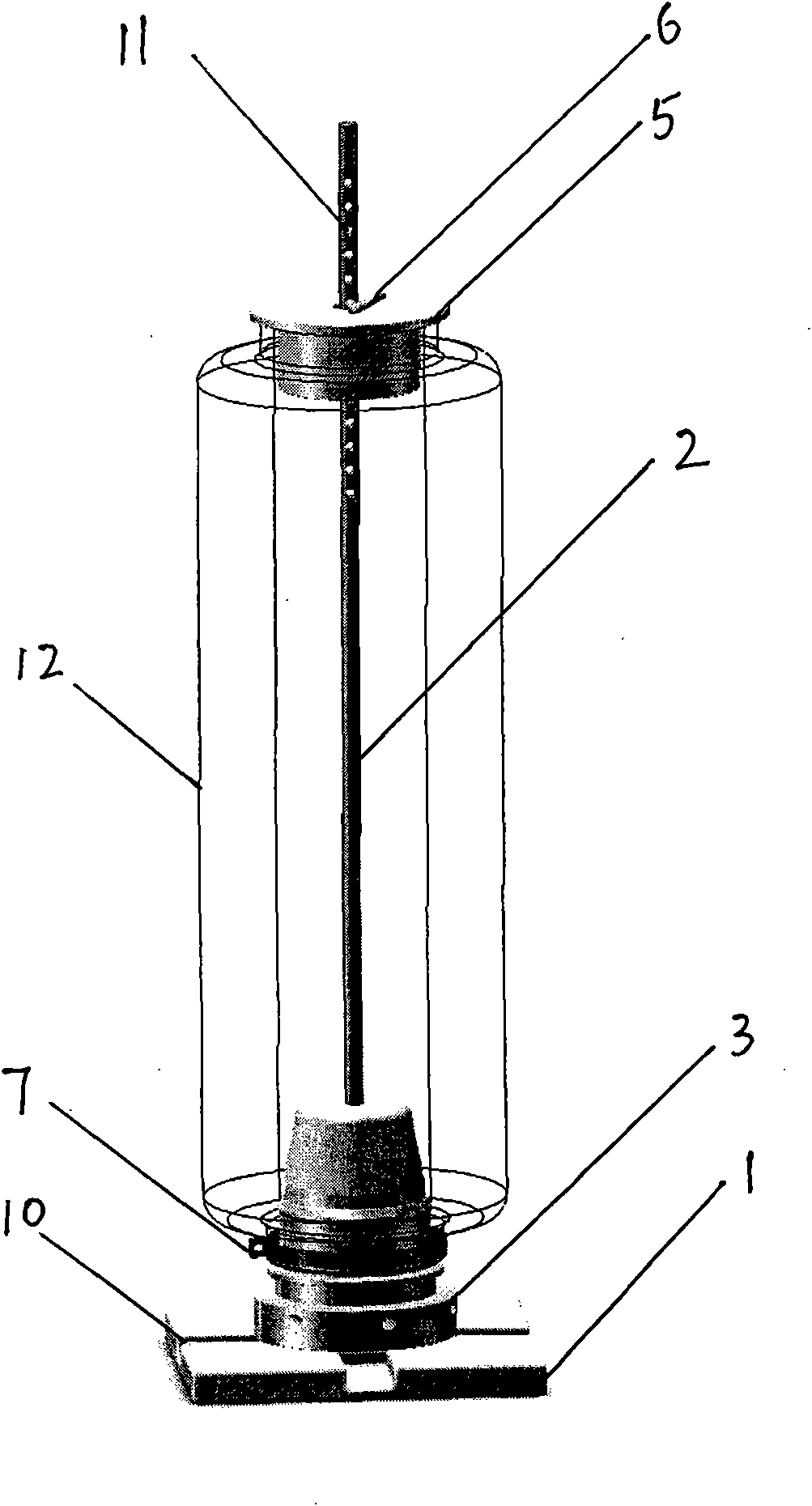

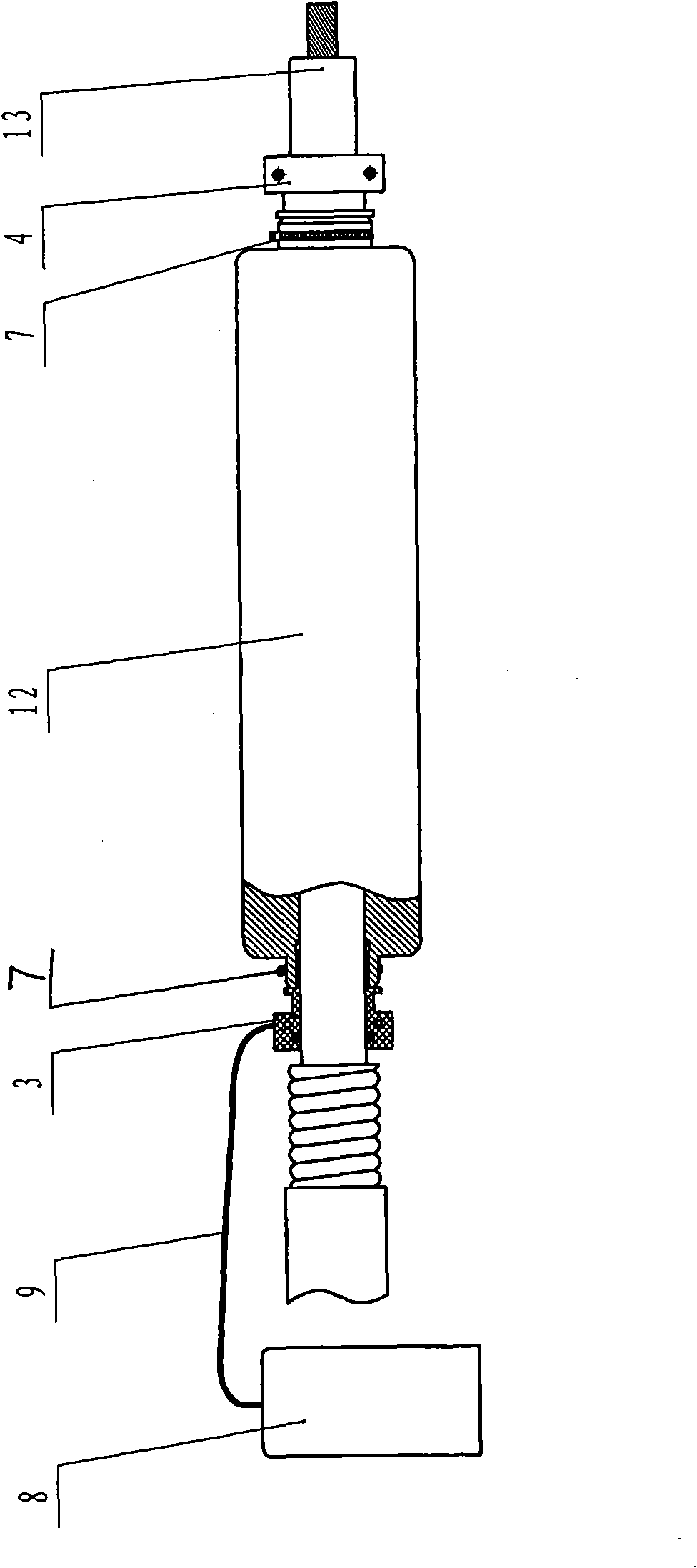

[0012] exist figure 1 Among them, before the intermediate connector is inserted into the cable, the method of inserting the half sleeve into the intermediate joint is used, and two pairs of half sleeves are respectively inserted into the inner cavities at both ends of the intermediate joint. First, on the base 1 with a hollow cone, put a A metal rod 2 that is longer than the intermediate joint 12 is fixed to the cone. There are many bolt holes 11 on the metal rod 2. The outer diameter of the cone is slightly smaller than the inner diameter of the half sleeve. A pair of half sleeves 3 with sealing rings are placed on the cone. Fix the bottom of the body with screws, and apply grease on the part of the half sleeve 3 that will be inserted into the intermediate joint, then put the intermediate joint 12 on the metal rod 2 and the half sleeve 3, insert the baffle plate 5 into the metal rod 2 and In contact with the other end of the joint 12, insert the pin 6 into the fastening hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com