Agricultural microporous plastic film puncher

A technology of microporous mulch and puncher, which is applied in metal processing and other directions, can solve the problems of time-consuming and laborious, low efficiency, and cannot meet the needs of large-area covering cultivation of crops, and achieves the effects of wide application range, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

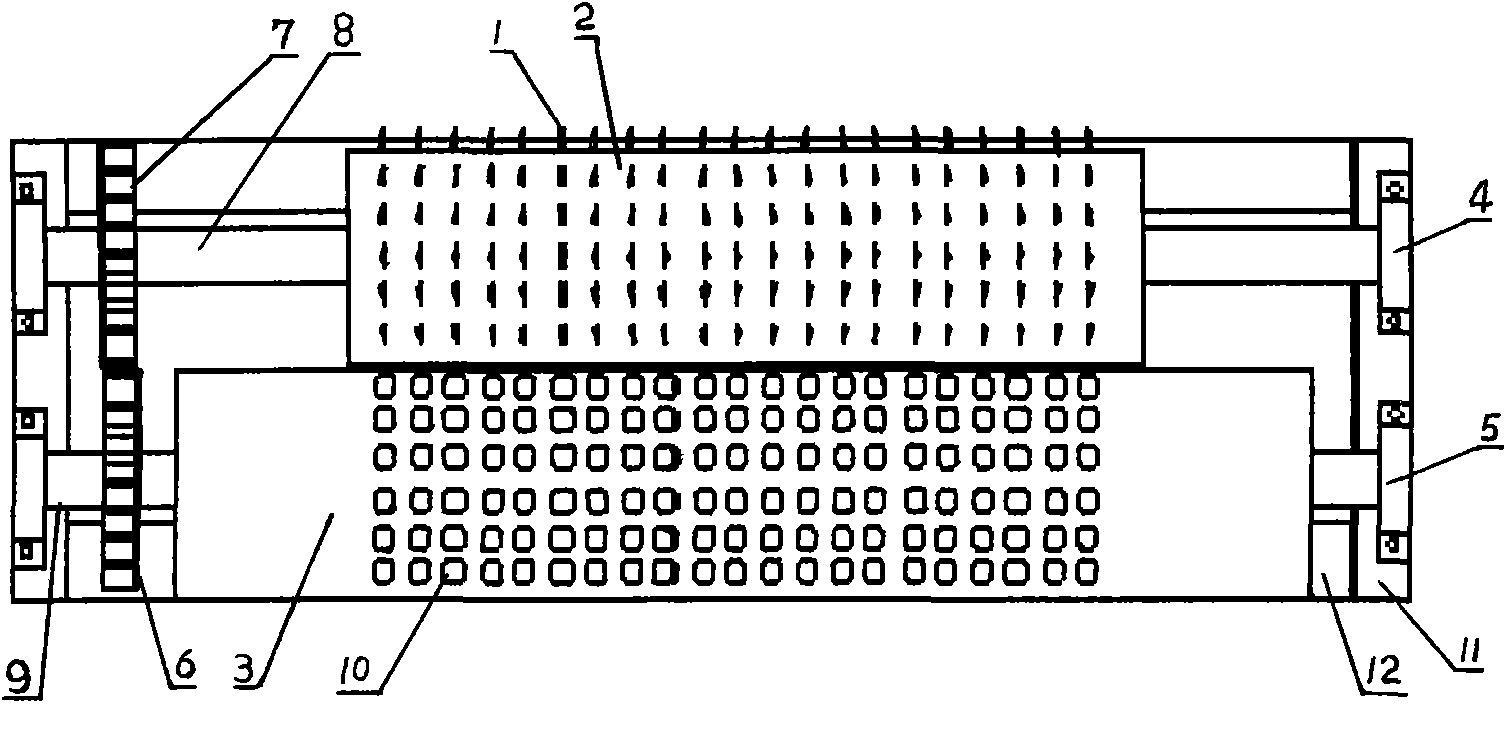

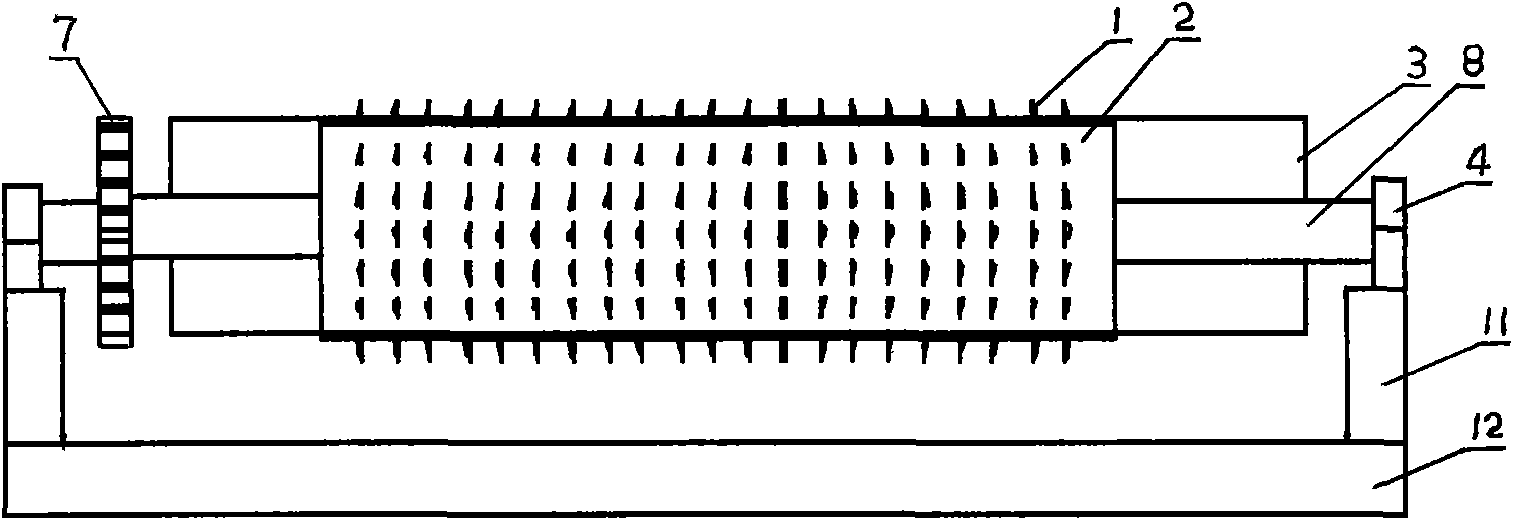

[0011] Needle roller surface 2 is made up of side by side thin wooden strips, and steel needle 1 is nailed on the thin wooden strips; The circular frame plate is fixed on the needle roller rotating shaft 8; the two ends of the needle roller rotating shaft 8 are installed on the side frame 11 through the bearing seat 4. Needle roller gear 7 and backup roller gear 6 are respectively installed at corresponding positions on the same side of needle roller rotating shaft 8 and backup roller rotating shaft 9 .

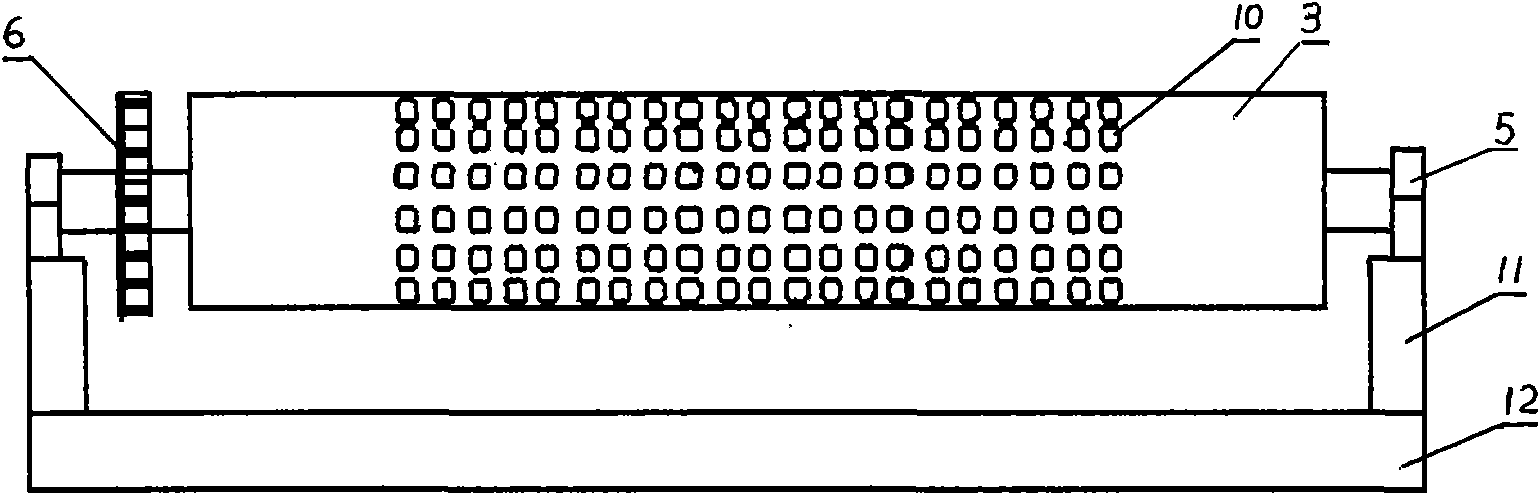

[0012] The pad roller surface 3 adopts PVC pipe material or other plastic pipes; both ends are fixed on the circular frame plate. The circular frame plate is fixed on the backing roller shaft 9; the backing roller surface 3 is drilled with a small hole 10, and the position of the small hole 10 corresponds to the position of the steel needle 1 on the needle roller surface 2. Backing roller rotating shaft 9 two ends are installed on the side frame 11 by bearing seat 5.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com