Water saving toilet with odor preventing pipe

A technology for water-saving toilets and pipes, which is applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

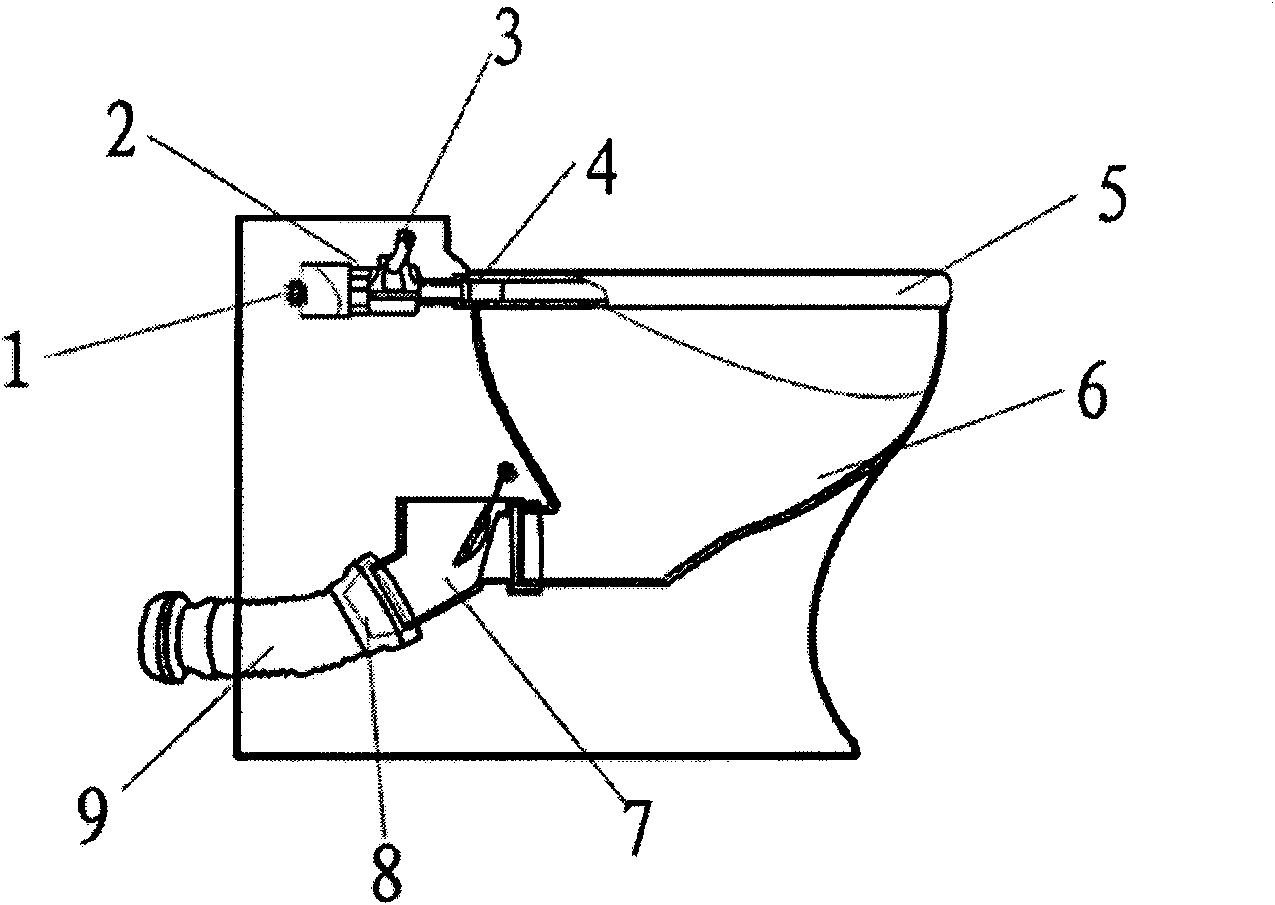

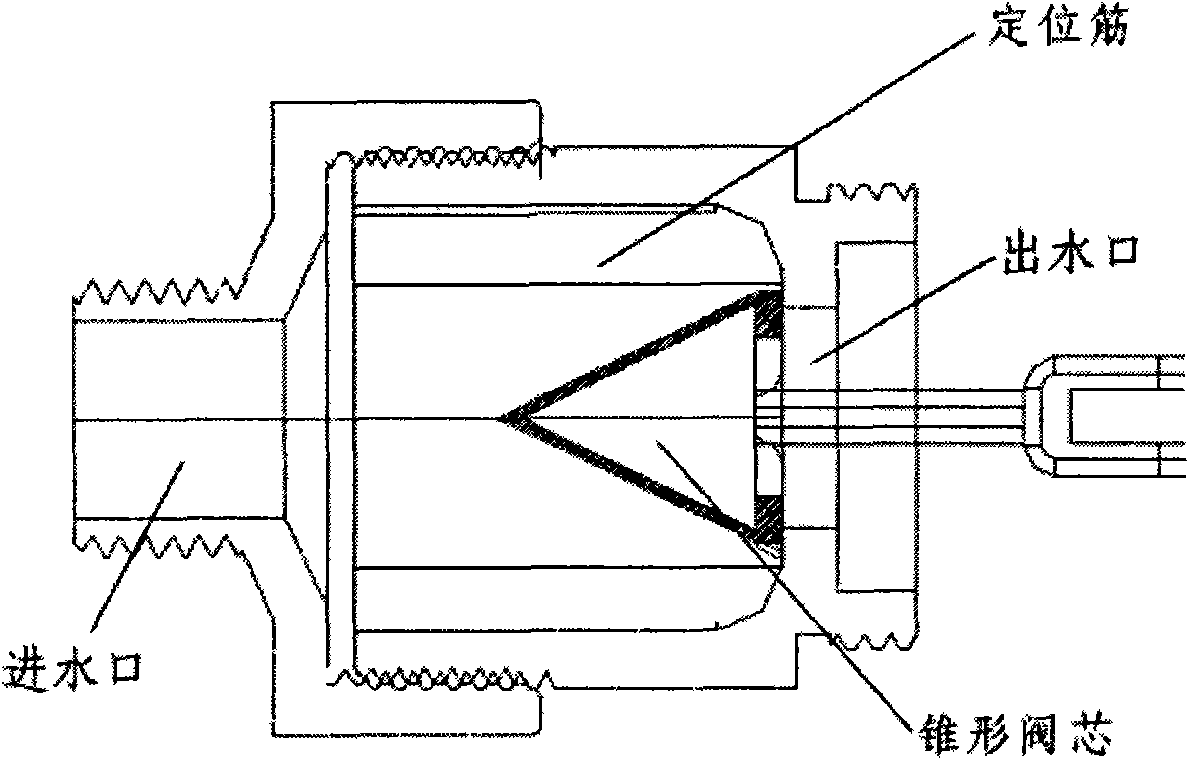

[0031] refer to figure 2 As shown, the tap water is connected from the pipeline, enters the water inlet valve 2 through the anti-siphon device 1, and the two ends of the anti-siphon device 1 are respectively placed at the inner and outer ends of the water inlet of the water inlet valve. The through hole part of the anti-siphon device 1 faces the direction of water inlet; the blind hole part is inside the water inlet valve. Tap water enters from the through hole part, and enters the water inlet valve through the gap between the blind hole part and the water inlet valve body. The driving device 10 drives the shift fork switch 3 to open the conical valve for flushing. The water inlet valve is connected with the water inlet 4 of the flush control circle, and the water enters the water distribution channel of the flush control circle 5 through the water inlet 4 of the flush control circle. of flushing. The driving external force disappears, the shift fork switch is returned to ...

Embodiment 2

[0033] refer to image 3 , the anti-siphon device 1 , the water inlet valve 2 and the drive device 10 in the first embodiment are replaced by an induction washer 11 . The water outlet of the induction washer 11 is connected with the water inlet 4 of the flushing control ring, and the induction washer 11 is connected with the electromagnetic force switch 12 for opening the drain valve 7 . The connection of the toilet bowl surface 6, the sewage valve 7, the pipeline odor-proof device 8, and the telescopic tube 9 is the same as in the first embodiment. During use, the induction confirmation time is set as required, and when the continuous induction time reaches the set time, the induction flusher 11 performs the first stage of a small amount of flushing for wetting the toilet bowl surface 6 to prevent sticking. After the first stage of flushing, continue to sense for a set time without interruption and then leave. The induction flushing device 11 performs the second stage of flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com