Close type large space tensioning steel-cable-membrane building

A large-space, closed-type technology, applied in the direction of architecture, building structure, etc., can solve the problems of tensioned steel-cable-membrane structure in large-scale closed space, etc., to maintain shape stability, simple construction equipment, The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

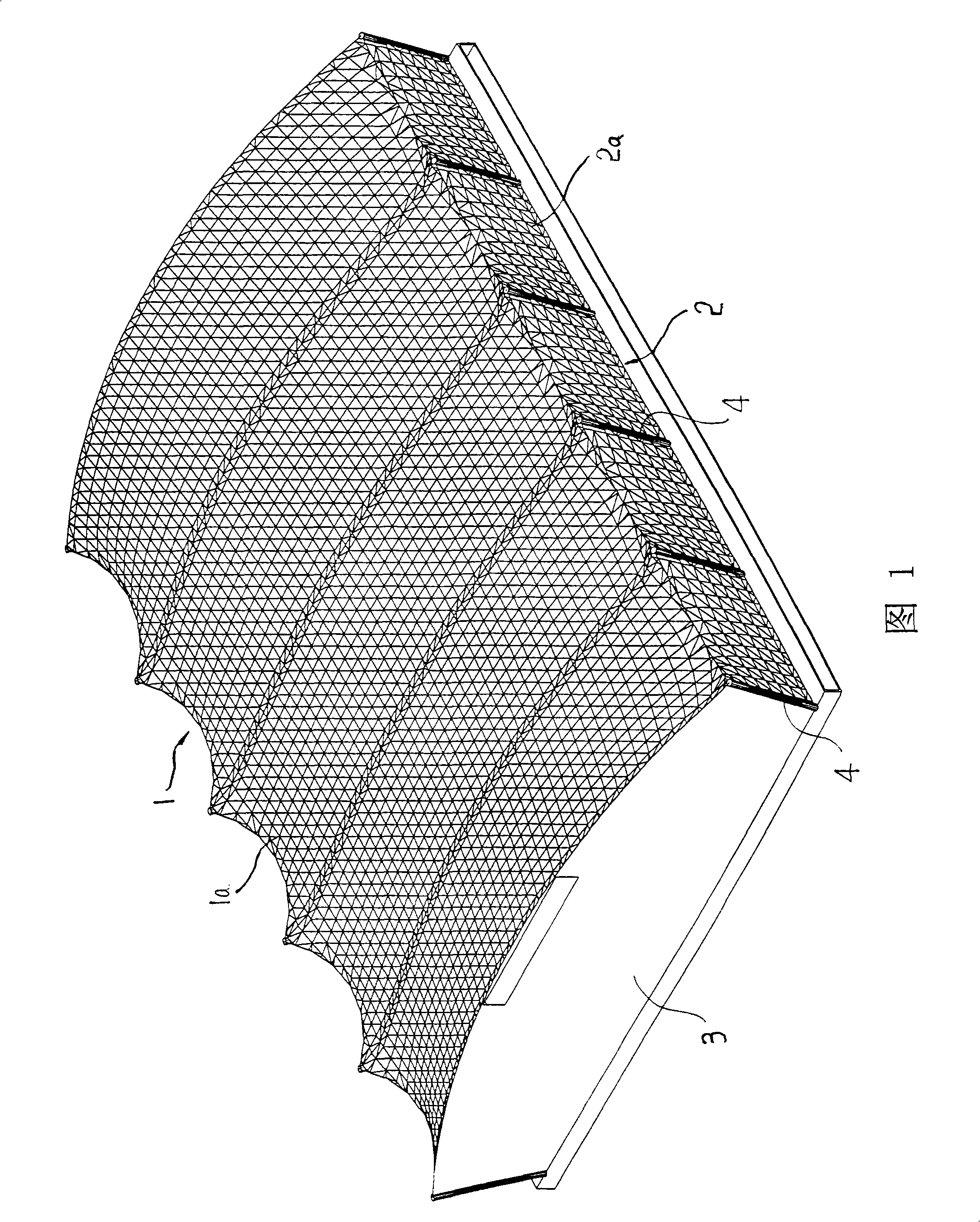

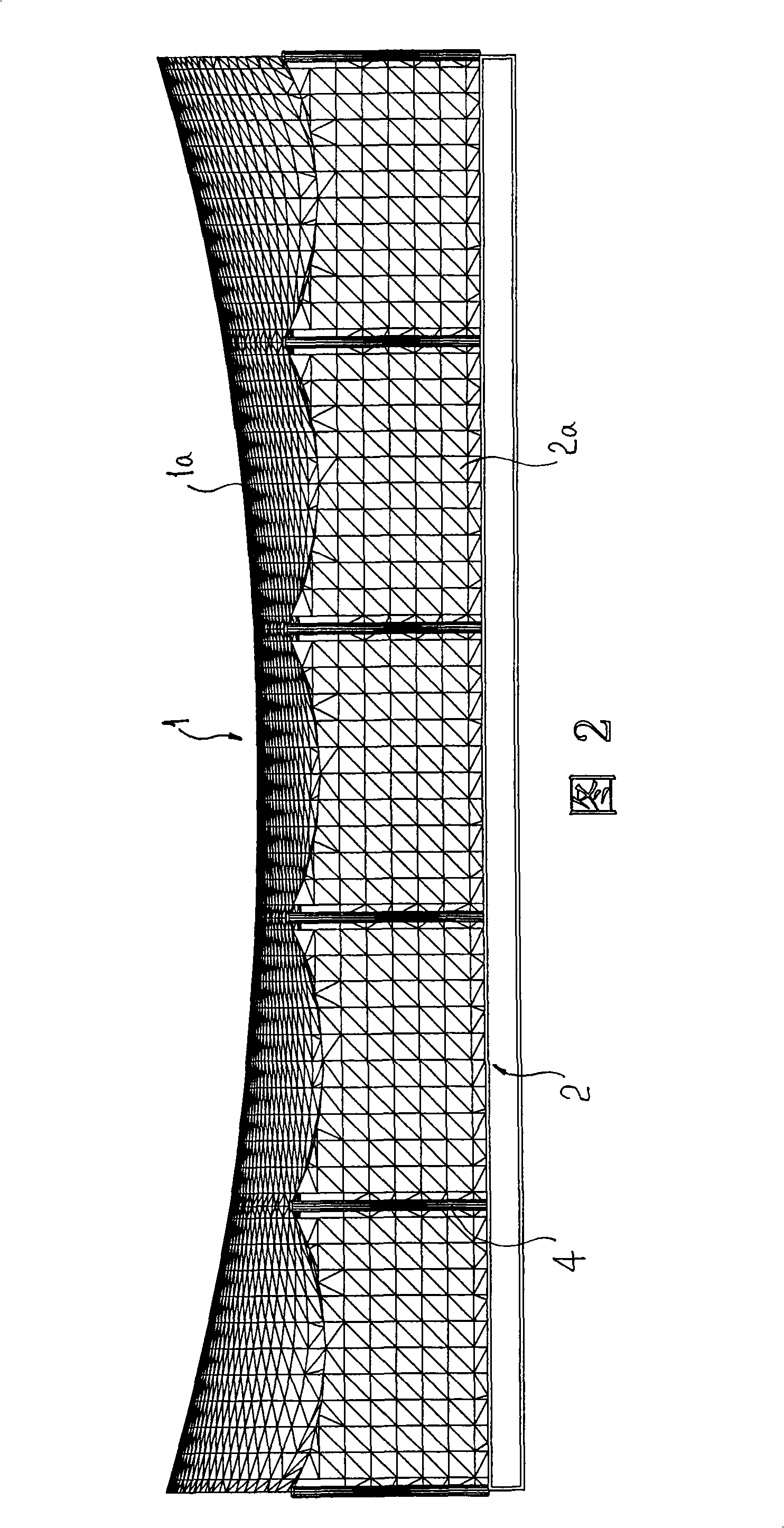

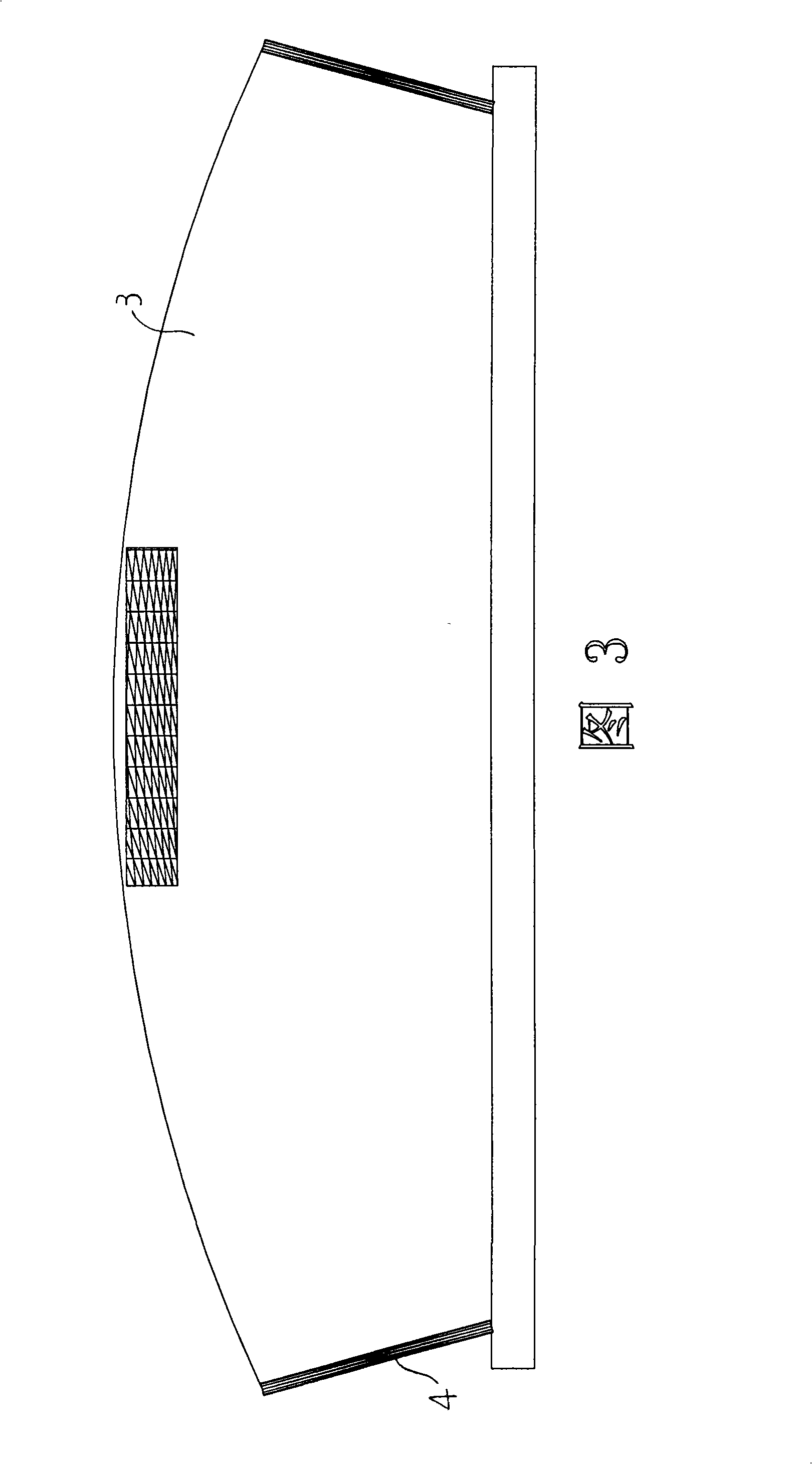

[0026] Referring to Figures 1 to 4, the enclosed large-space tensioned steel-cable-membrane building of the present invention includes a top 1, a side elevation 2 and a gable 3 at both ends. The side elevation 2 is composed of multiple tensioned membranes The structural blocks 2a are continuously combined in a longitudinal direction. Each tensile membrane structural block 2a is connected by a rigid boundary member 4; the gable 3 is a rigid structure with a middle height and a low side; the membrane block 1a on the top 1 is composed of The top of the rigid boundary member 4 and the top of the gable 3 at both ends are supported by a steel cable mesh composed of multiple longitudinal and transverse prestressed steel cables. The top 1 is in the longitudinal section of the middle part of the membrane block 1a than the gable 3 at both ends. Low, the middle part of the membrane block 1a on the horizontal section of the top 1 is higher than the two sides, so that the vertical or horizon...

Embodiment 2

[0028] Refer to Figures 4 to 8, which is another enclosed large-space tensile steel-cable-membrane building of the present invention. It includes a top 1, a side elevation 2 and a gable 3 at both ends. The side elevation 2 is composed of multiple Tensile membrane structure blocks 2a are continuously combined in a longitudinal direction, and rigid boundary members 4 are connected between each tensile membrane structure block 2a; the gable 3 is a rigid structure with low middle and high sides; the membrane on the top 1 The block 1a is supported by a steel cable net composed of a plurality of longitudinal and transverse prestressed steel cables pulled through between the top of the rigid boundary member 4 and the tops of the gables 3 at both ends. The top 1 is in the middle of the membrane block 1a in the middle longitudinal section. It is higher than the gables 3 at both ends, and the middle part of the membrane block 1a on the horizontal section of the top 1 is slightly lower tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com