Electrostatic atomization device

An electrostatic atomization, high-voltage technology, applied in the direction of spraying electric energy devices, output power conversion devices, electrical components, etc., can solve the problems of complex circuit structure, cost and volume increase of electrostatic atomization devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

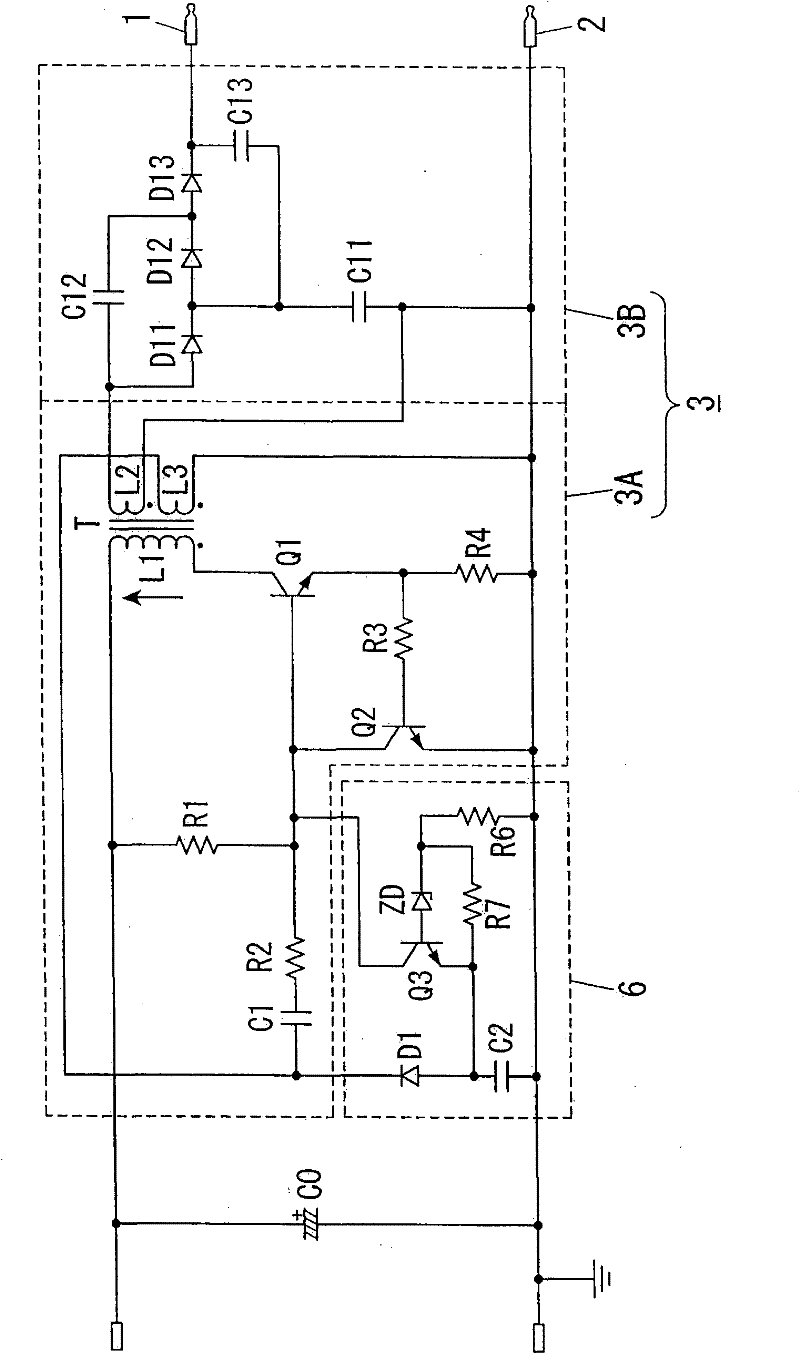

[0017] Such as figure 2 As shown, the electrostatic atomization device according to the first embodiment of the present invention includes: a discharge electrode 1; The electrode 2 has a circular inner edge as a substantial electrode; a high voltage generating circuit 3 for applying a high voltage between the discharge electrode and the counter electrodes 1, 2 to cause a discharge therebetween; and for stabilizing An output stabilization circuit 6 for the output voltage of the high voltage generation circuit 3 . In the first embodiment, the counter electrode 2 provided in the electrostatic atomization device is grounded. During the discharge process, a high negative or positive voltage (such as a negative voltage of several thousand volts) is applied to the discharge electrode 1 . At the same time, liquid (such as water) is supplied to the discharge electrode 1 through an existing supplier (such as a water tank or a cooler described in "Background Art", not shown in the fig...

no. 2 approach

[0028] Such as image 3 As shown, like the electrostatic atomizing device of the first embodiment, the electrostatic atomizing device of the second embodiment of the present invention includes a discharge electrode 1 , a counter electrode 2 , a high voltage generating circuit 3 and an output stabilizing circuit 6 . The electrostatic atomization device of the second embodiment is characterized in that it further includes: a discharge current detection circuit 4 that detects a discharge current flowing between the discharge electrode and the counter electrodes 1, 2 through the counter electrode 2; and a discharge current detection circuit based on 4, the control circuit 5 that controls the output of the high voltage generating circuit 3 in such a manner as to maintain a required discharge state, wherein the operating power of the control circuit 5 is obtained from a reference voltage.

[0029] Figure 4 It is a circuit diagram showing a specific circuit configuration of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com