Device and method for x-ray tube focal spot size and position control

An X-ray tube and focal spot technology, applied in the field of X-ray tube focal spot parameter control, can solve the problems of expensive, non-existent focal spot size, etc., and achieve the effect of avoiding artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

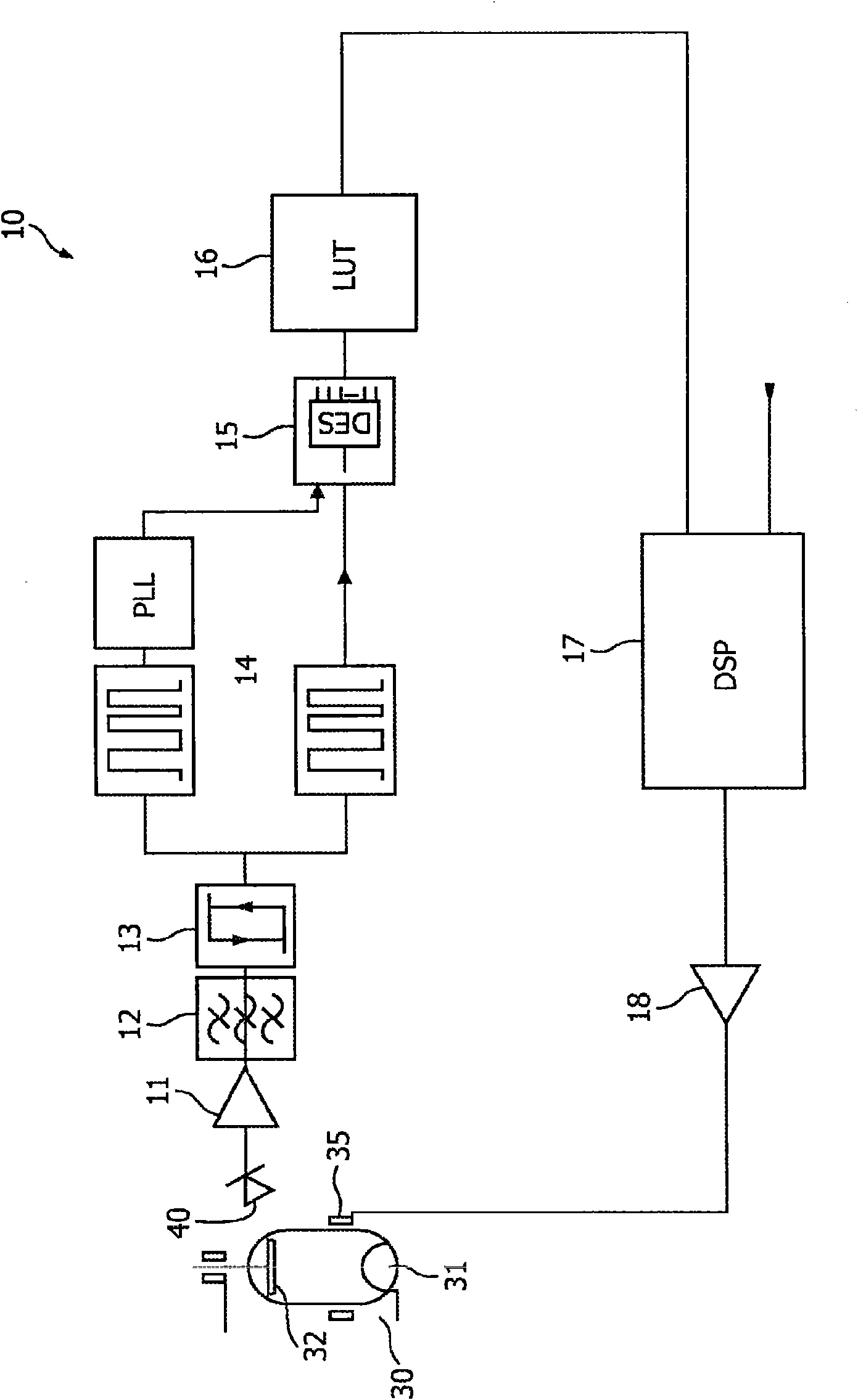

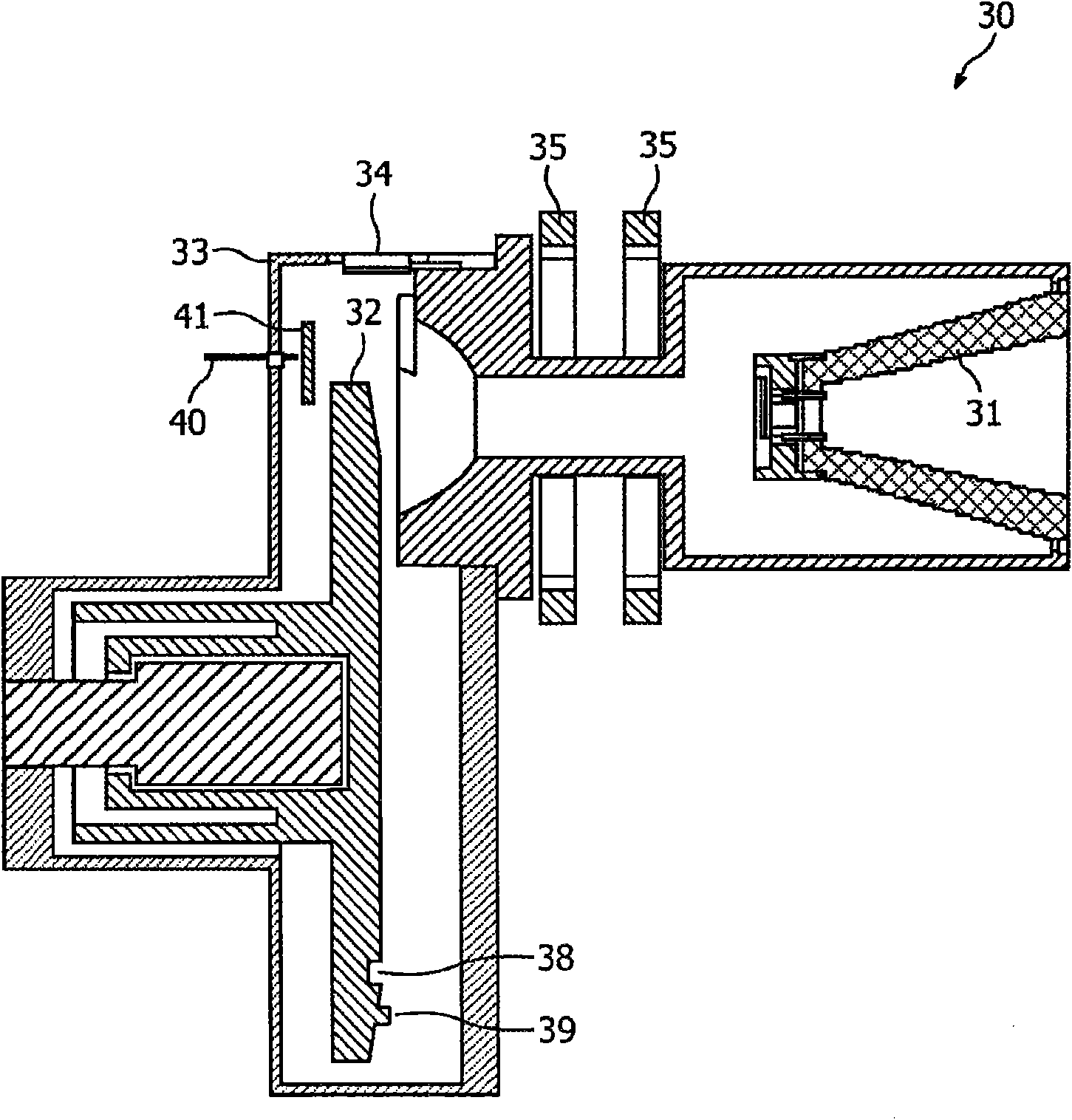

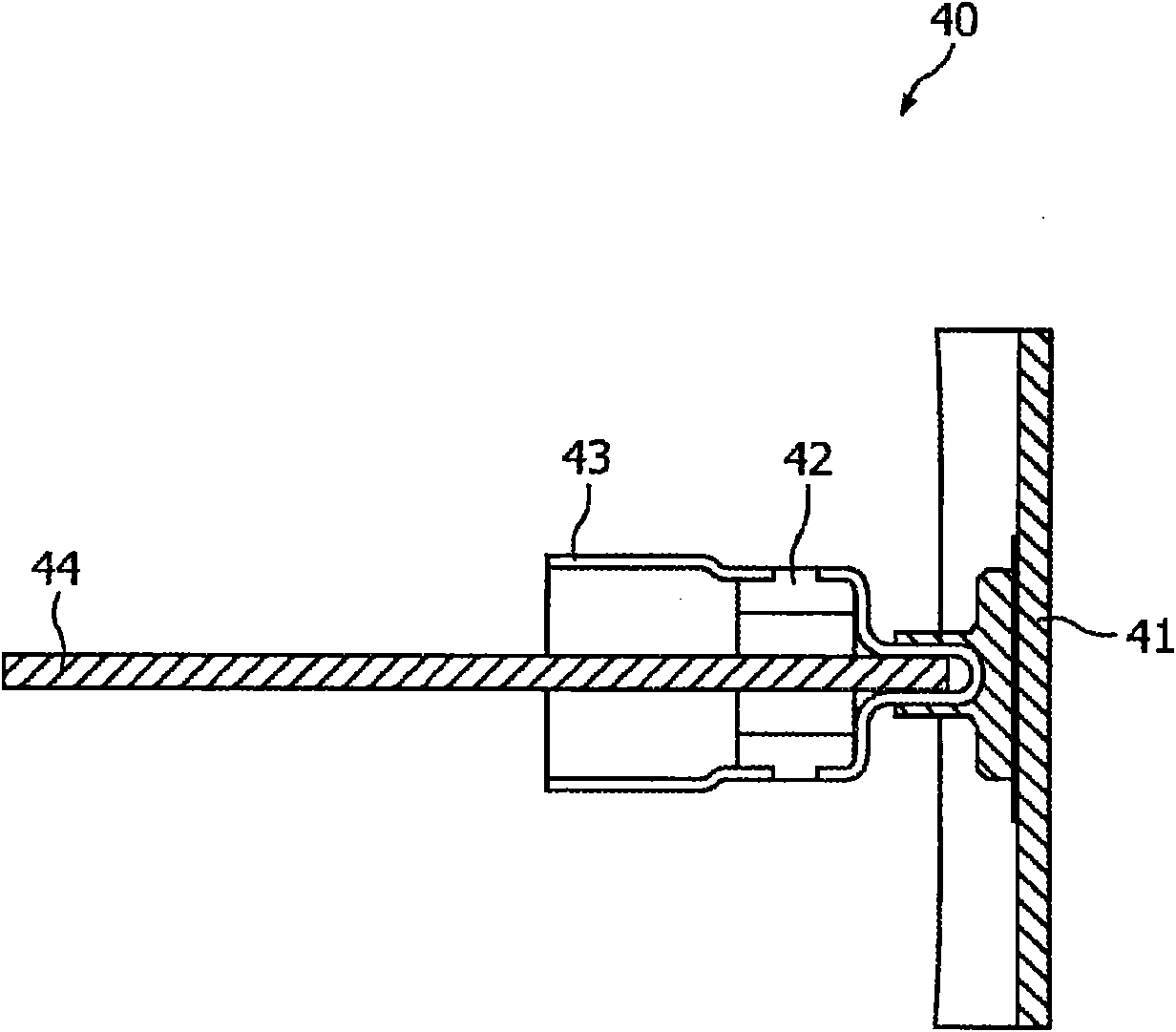

[0041] figure 1 An apparatus for providing control signals to control focal spot parameters of a focal spot on an anode 32 of an X-ray tube is shown. The device comprises an interface 11 for receiving a signal having a characteristic pattern depending on stray electrons detected in the X-ray tube 30 . The X-ray tube is shown for explanatory purposes only and is therefore shown schematically. The X-ray tube comprises an emitter 31 and an anode 32, wherein the emitter is adapted to emit electrons towards the anode. The detection unit 40 is shown outside the X-ray tube 30 for explanatory purposes only, and may also be placed inside the X-ray tube 30, in particular when detecting stray electrons. The X-ray tube also includes a deflection yoke 35 . The interface 11 can be terminal, but can also be equipped with an amplifier for amplifying the received signal. The interface 11 may also include any processing utilities for processing received signals where appropriate. figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com