Electric motor stator

A stator and stator core technology, applied in the stator field, can solve the problems of difficult winding space, winding stuck into the cutting part, difficult high-density and high-efficiency winding operation, etc., and achieve the effect of homogeneous winding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

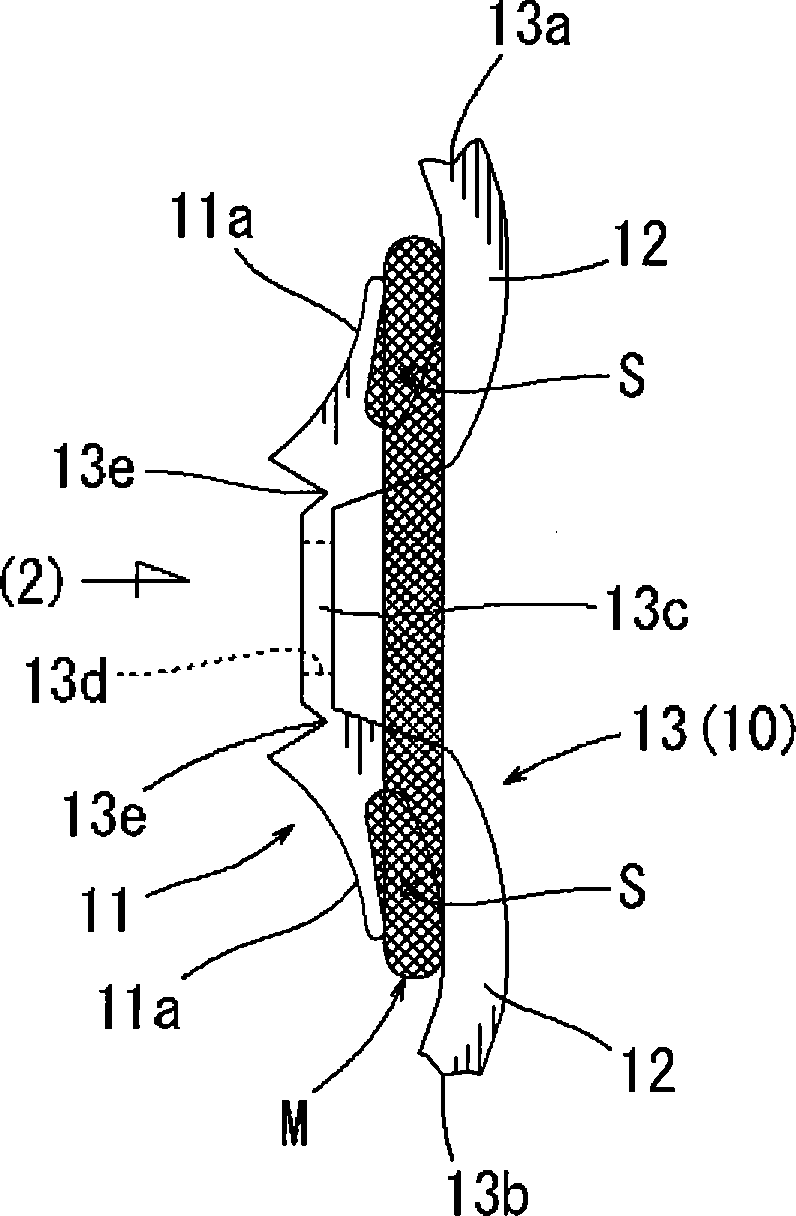

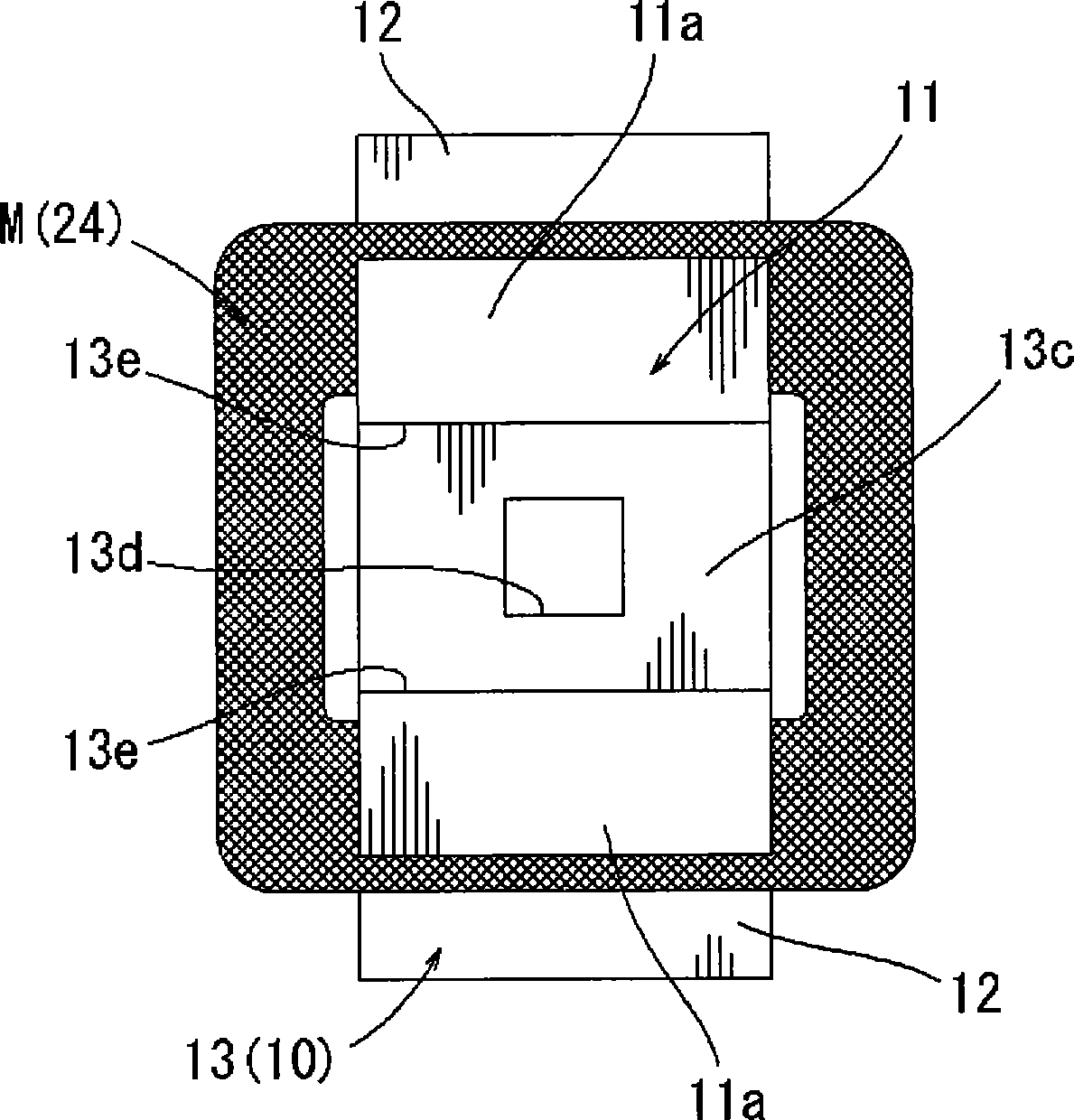

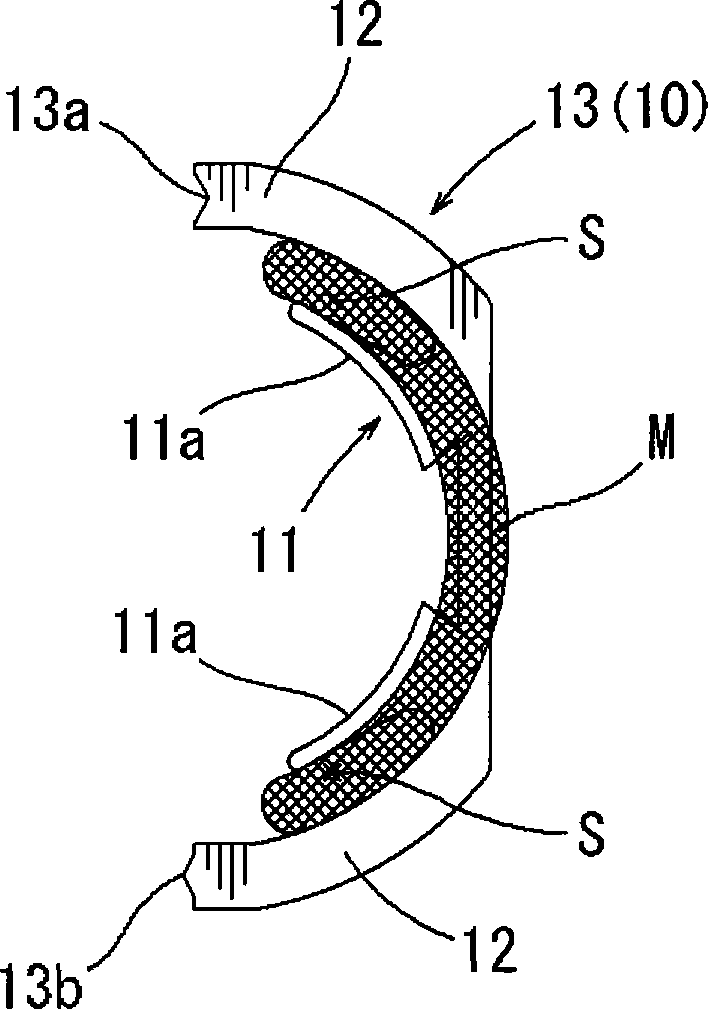

[0040] Below, according to the attached Figure 1-13 Embodiments of the present invention will be described. As one of the examples of the stator of the motor, in the embodiments described below, a two-pole stator in which two magnetic pole teeth face each other is taken as an example. Figure 4 The stator 1 in the first embodiment is shown. The stator core 10 of the stator 1 has a substantially circular shape when viewed from the axial direction of the motor, and a rotor R is provided on the inner peripheral side after the magnetic pole teeth of the stator core 10 are wound. The stator core 10 is formed by laminating a plurality of thin steel plates punched by a punching press to form a whole, and has two magnetic pole teeth 11 facing each other on the inner peripheral side.

[0041] Such as Figure 5 As shown in , the stator core 10 can be divided into two segments (two core splits 13) in the approximate center of the ring, and the two magnetic pole teeth 11 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com