Method for improving viscous-elastic behaviour of frozen oat dough by transglutaminase

A technology of transglutaminase and viscoelastic properties, applied in the field of food processing, can solve problems such as poor taste, poor product texture, restricted development, etc., so as to increase nutritional value and functional properties, and solve the change of texture and taste. Poor, the effect of improving viscoelastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

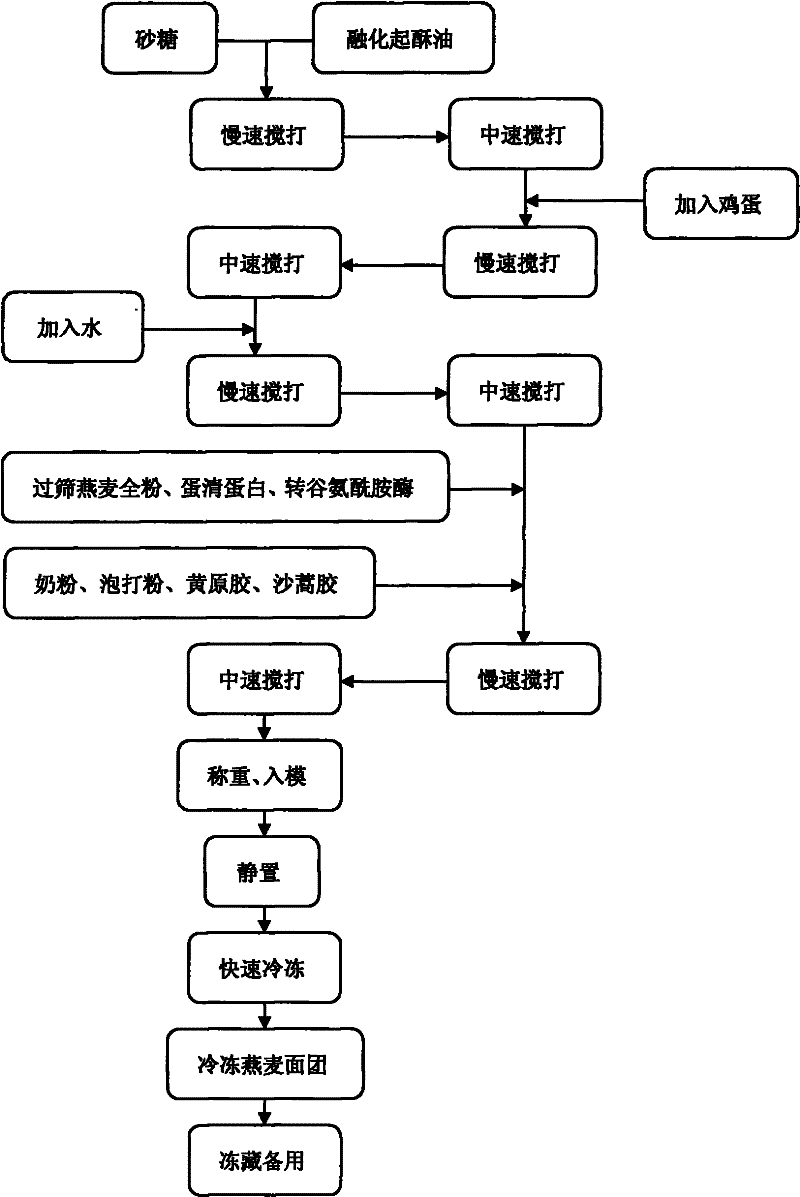

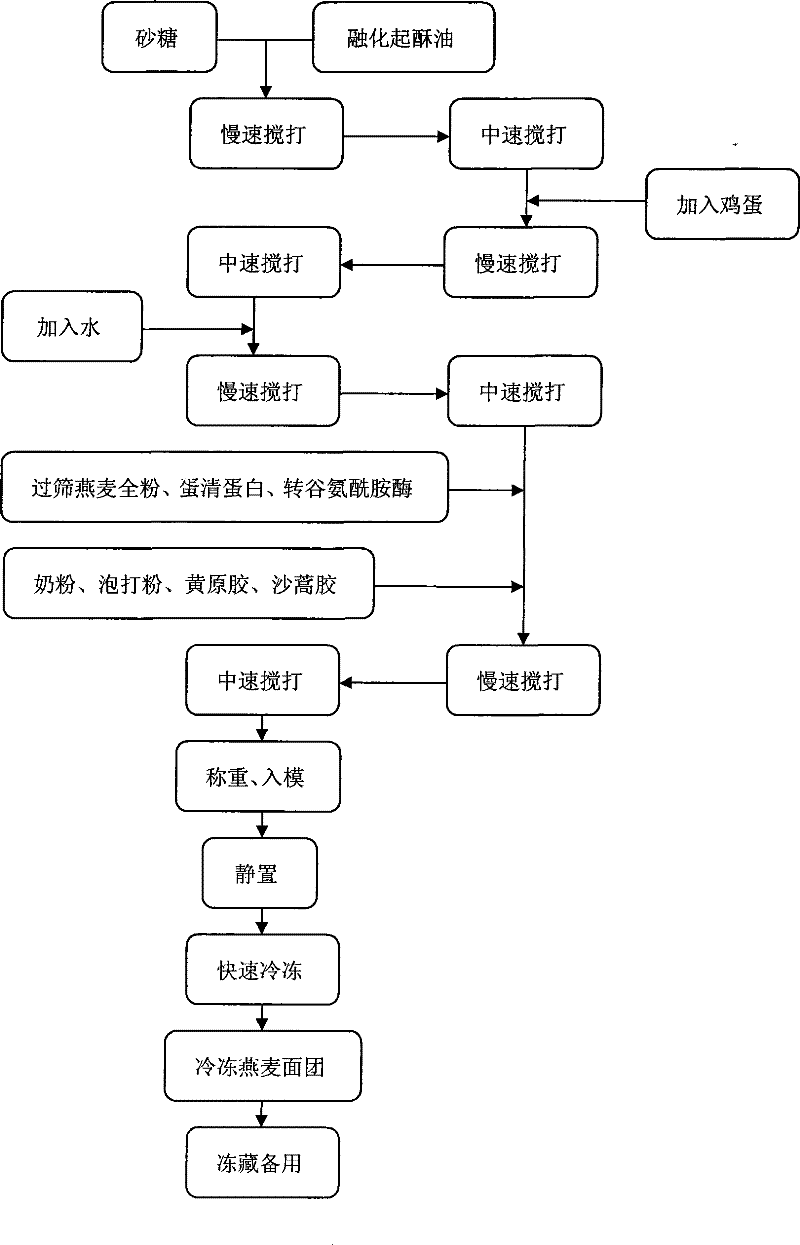

Image

Examples

Embodiment 1

[0019] In the embodiment of the present invention, 20% by weight of sifted oat powder, 19% by weight of shortening, 14% by weight of sugar, 19% by weight of egg net weight, 3% by weight of milk powder, 1.5% by weight of baking powder, 21% by weight of water, xanthogen 0.1% by weight of gum, 0.1% by weight of Artemisia gum, 2% by weight of egg white protein, and 0.2% by weight of transglutaminase.

[0020] First, take the shortening and melt it at room temperature for 20 minutes, then whip it together with the sugar in the mixing tank at slow speed for about 1 minute, and then change to medium speed after mixing, and beat until the material in the tank changes from yellow to white, about 20 minutes minutes, then add eggs one by one while whisking at slow speed, continue to beat at medium speed until uniform, then add water and beat at slow speed for 1 minute, then beat at medium speed for 2 minutes, and finally add sifted oat flour, egg white protein, Continue to beat the mixtu...

Embodiment 2

[0022] In the embodiment of the present invention, 25% by weight of sifted oat powder, 15% by weight of shortening, 15% by weight of sugar, 15% by weight of egg net weight, 4% by weight of milk powder, 0.8% by weight of baking powder, 19% by weight of water, 19% by weight of xanthogen 0.05% by weight of gum, 0.05% by weight of artemisia gum, 5% by weight of egg white protein, and 0.5% by weight of transglutaminase.

[0023] First, take the shortening and melt it at room temperature for 25 minutes, then whip it together with the sugar in the mixing tank at slow speed for 1 minute, and then change to medium speed after mixing, and beat until the material in the tank changes from yellow to white, about 17 minutes , then add the eggs one by one while whisking at a slow speed, continue to beat at medium speed until uniform, then add water and beat at slow speed for 1 minute, then beat at medium speed for 3 minutes, and finally add sifted oat flour, egg white protein, turn Continue ...

Embodiment 3

[0025] In the embodiment of the present invention, 22% by weight of sifted oat powder, 17% by weight of shortening, 17% by weight of granulated sugar, 17% by weight of egg net weight, 4% by weight of milk powder, 1.0% by weight of baking powder, 18% by weight of water, 18% by weight of xanthogen 0.08% by weight of gum, 0.08% by weight of artemisia gum, 3.5% by weight of egg white protein, and 0.3% by weight of transglutaminase.

[0026] First, take the shortening and melt it at room temperature for 30 minutes, then whip it together with the sugar in the mixing tank at slow speed for about 1 minute, and then change to medium speed after mixing, and beat until the material in the tank changes from yellow to white, about 20 minutes minutes, then add eggs one by one while whisking at slow speed, continue beating at medium speed until uniform, then add water and beating at slow speed for 1 minute, then whisk at medium speed for 3 minutes, and finally add whole oat flour, egg white p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com