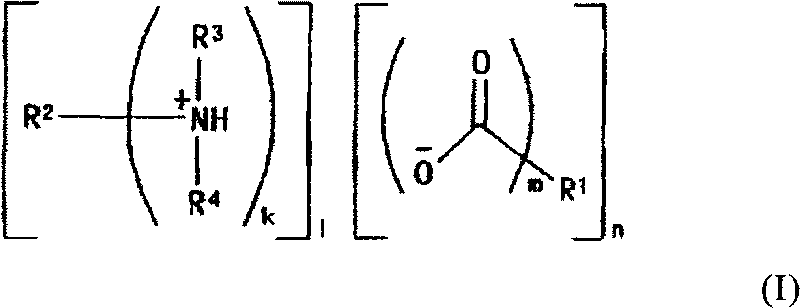

Hydroxy acid amine salt, method for producing the same, and rubber composition containing the same

A kind of hydroxy acid amine salt, hydroxyl technology, applied in the field of hydroxy acid amine salt and its manufacture and the rubber composition containing this hydroxy acid amine salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The present invention will be described in more detail below with reference to the examples and comparative examples shown below. Of course, the technical scope of the present invention is not limited to these examples.

[0036] Analysis

[0037] The hydroxyacid amine salt (cyclohexylamine malate) used in Example 1 below, the amine hydroxyacid salt (cyclohexylamine tartrate) used in Example 2 below, and the comparative amine used in Comparative Example 2 Salt (cyclohexylamine succinate) was synthesized by the following synthetic method, and NMR spectroscopy was used according to the following steps ( 1 H-NMR and 13 C-NMR) and elemental analysis were analyzed to identify its chemical structure.

[0038] (1) NMR spectroscopy ( 1 H-NMR and 13 C-NMR)

[0039] Perform nuclear magnetic resonance spectroscopy ( 1 H-NMR and 13 During C-NMR), nuclear magnetic resonance spectrometer analyzer AV400M (400MHz) produced by BRUKER was used, and deuterated dimethyl sulfoxide (de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com