An acrylic adhesive and a foam tape

An acrylic and adhesive technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve problems such as unsatisfactory bonding performance, achieve strong practicability, improve viscoelastic properties, ultra-low temperature and high weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

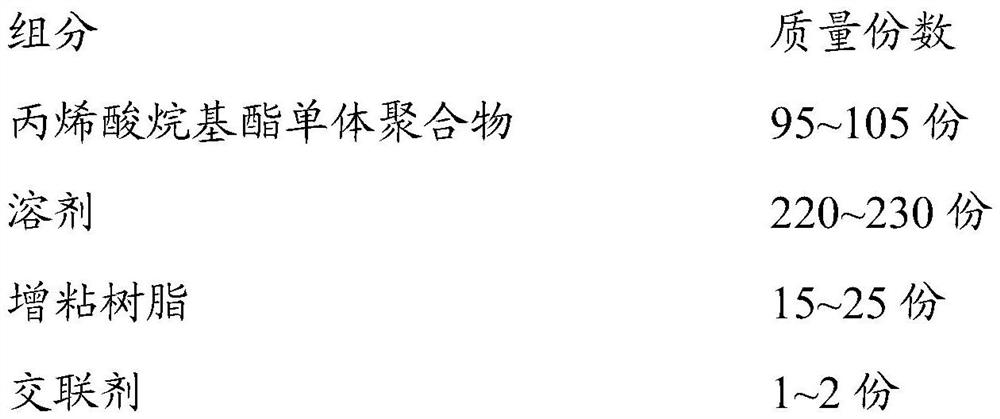

Method used

Image

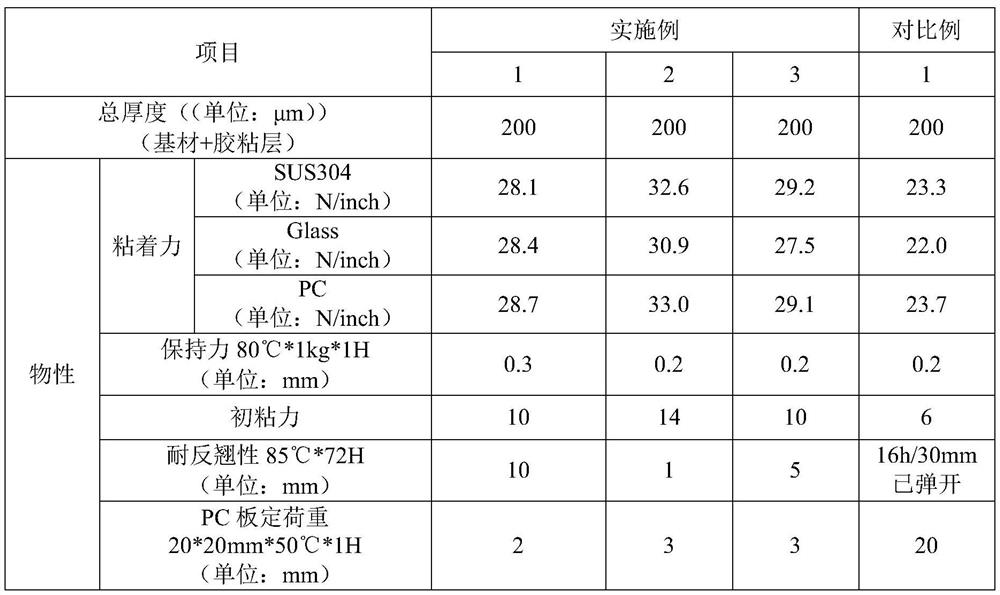

Examples

Embodiment 1

[0023] A foam adhesive tape, comprising a substrate layer, a first adhesive layer arranged on one side of the substrate layer, a second adhesive layer arranged on the other side of the substrate layer, arranged on the first The first release film layer on the other side of the adhesive layer, and the second release film layer on the other side of the second adhesive layer. The above-mentioned acrylic adhesive used in the first adhesive layer and the second adhesive layer.

[0024] Preferably, the substrate used in the substrate layer is a foam substrate, and the foam substrate is selected from polyethylene foam, polyolefin foam, polypropylene foam, polyurethane foam and ethylene foam. - One of vinyl acetate copolymer foams. The foam base material is open-cell foam, semi-open-cell foam or closed-cell foam, and the color can be black, white or gray.

[0025] As preferably, the tensile strength of the foam base material, the mechanical stretching direction (MD direction) ≥ 10MP...

Embodiment 2

[0033] The difference between embodiment two and embodiment one is that the preparation method of the acrylic adhesive is as follows: 2.6 parts by mass of acrylic acid, 0.05 parts by mass of hydroxyethyl acrylate, 67 parts by weight of n-butyl acrylate, 30 parts by mass of 17 acrylate and as Put 100 parts by weight of toluene as a polymerization solvent into a three-necked flask, remove the oxygen in the polymerization system as much as possible, add 0.1 parts by weight of AIBN dissolved in a small amount of ethyl acetate, the exothermic reaction starts, and cool when the temperature rises to 75 °C Keep the temperature for 1 hour, add 0.1 parts by mass of AIBN dissolved in a small amount of ethyl acetate, raise the temperature to 85°C, hold the temperature for 2 hours, add 0.15 parts by mass of AIBN dissolved in a small amount of ethyl acetate for 5 hours The temperature was maintained at 85°C, and when the temperature was maintained and cooled to below 70°C, 50 parts by mass o...

Embodiment 3

[0035] The difference between embodiment three and embodiment one is that, in the acrylic adhesive, 20 parts by weight of rosin resin (manufactured by Arakawa Chemical Co., Ltd.) with a softening point of 135° C. is added to 100 parts by weight of its solid content, and 73 parts by weight are added at the same time. Parts by mass of ethyl acetate to prepare an acrylic adhesive with a solid content of 35%, and the viscosity of the adhesive at 23±2° C. is 5000 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical stretch | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com