Rotating arm type antifreezing fluid spraying device for two-lane coal trains

A spraying device and two-lane technology, which is applied to the spraying device with movable outlet, spraying device, transportation and packaging, etc., can solve the problem that the inner wall of the car cannot be uniformly sprayed, the spraying effect of the inner wall of the car is uneven, and the nozzle cannot automatically change the angle, etc. problems, to achieve the effect of convenient installation, flexible rotation, and ensuring safe passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

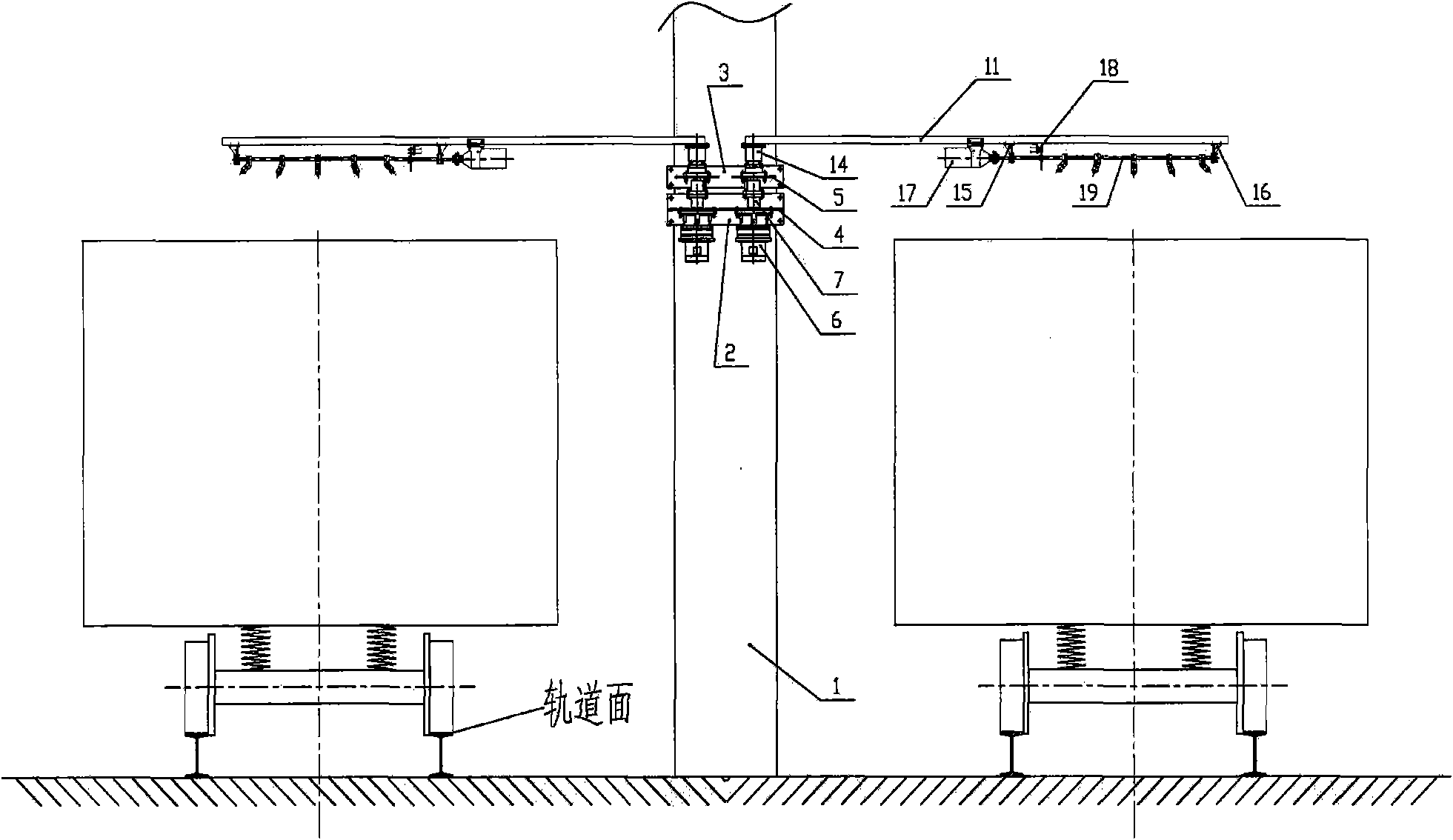

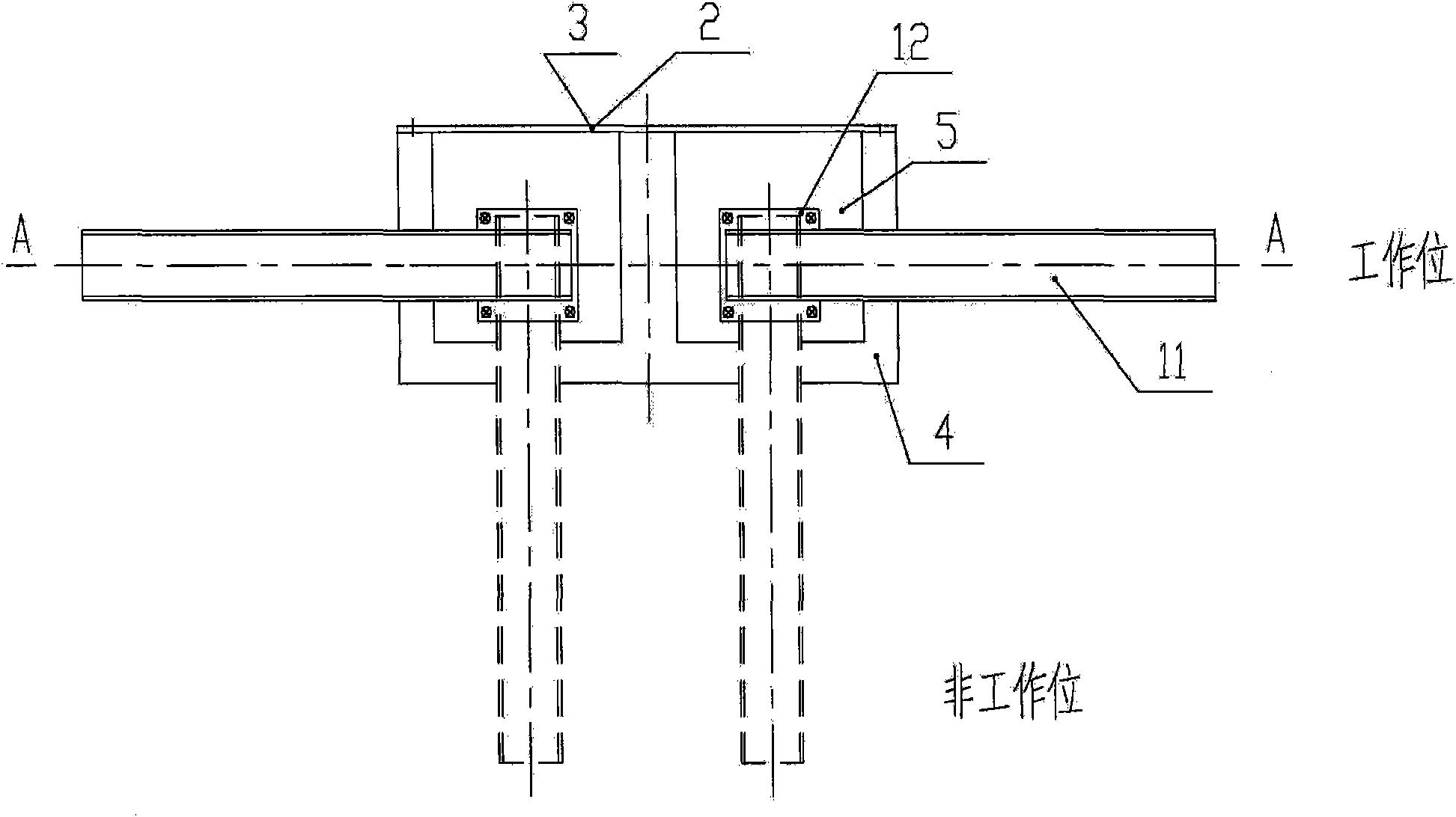

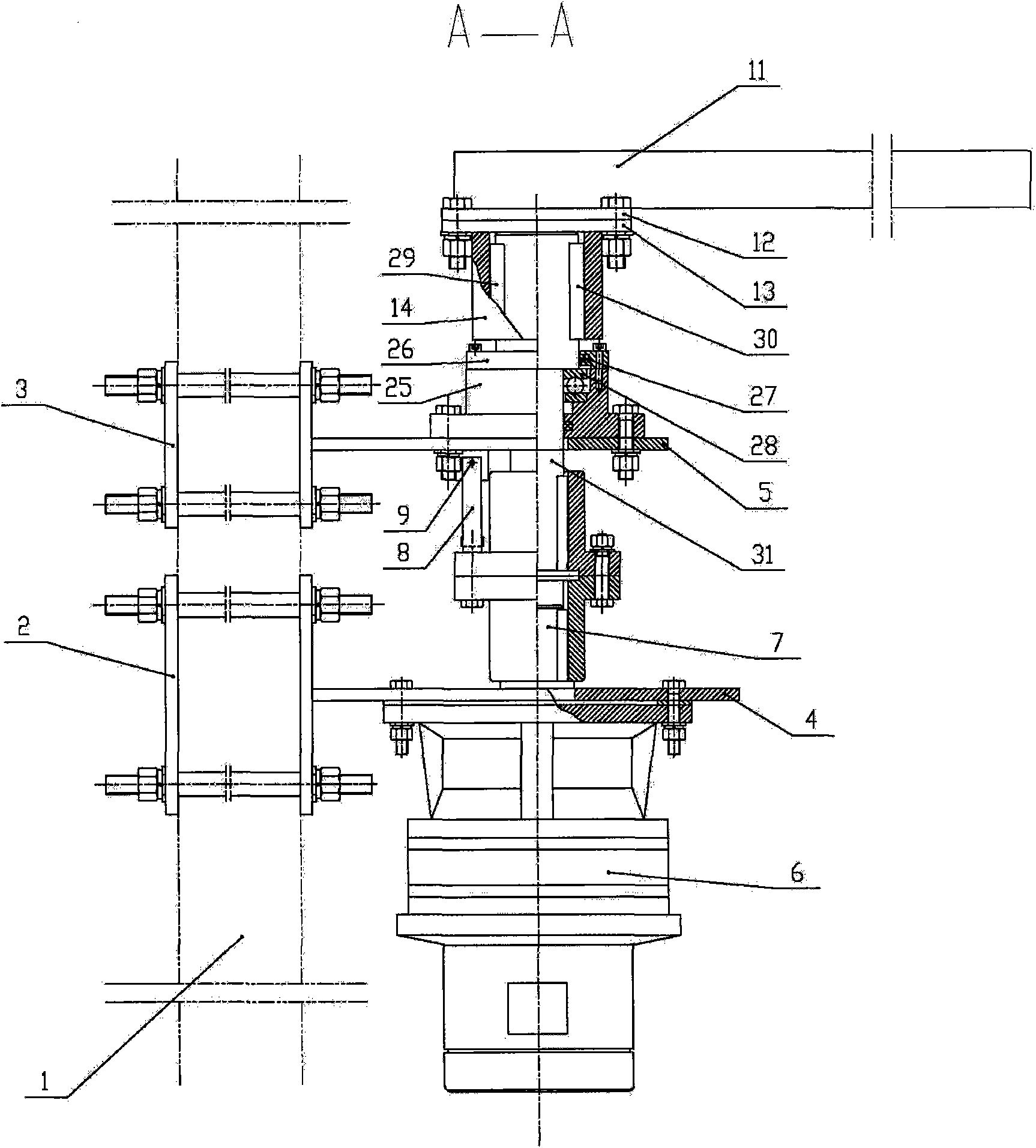

[0025] Such as figure 1 , 2 Shown in and 3: the present invention is used for the cantilever type two-lane coal train antifreeze spraying device of the two-lane coal train, which consists of a square column 1, a side-mounted fastening device, a drive deceleration mechanism, a rotary mechanism, and an upper connecting plate 12. The lower connecting plate 13. It is composed of multi-directional nozzle steering mechanism and control system. The side-mounted fastening device is on the square column 1 relying on its two vertical sides perpendicular to the track surface, and the bolts pass through the lower fastening splint 2. and the holes of the upper fastening splint 3, so that the splint is fixed and clamped on the two vertical sides of the square column 1 by the pre-tightening force of the bolts, and the lower installation platform 4 and the upper installation platform 5 are respectively vertically welded in the middle of the two splints. , and vertical shaft holes at the same a...

Embodiment approach 2

[0026] Embodiment 2: 5 groups of nozzle seats are sequentially installed at intervals of 300mm on the rotating shaft 19;

Embodiment approach 3

[0027] Embodiment 3: 5 groups of nozzle seats are sequentially installed at intervals of 280mm on the rotating shaft 19;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com