Double-sided multi-electrode penetrable electric arc welding method

An arc welding method and multi-electrode technology, which are applied in arc welding equipment, welding equipment, electrode support devices, etc., can solve the problems of sensitive groove gap workpiece deformation, welding parameters can only be adjusted at the same time, and cannot be applied to thin plate welding. High economy, strong operability, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

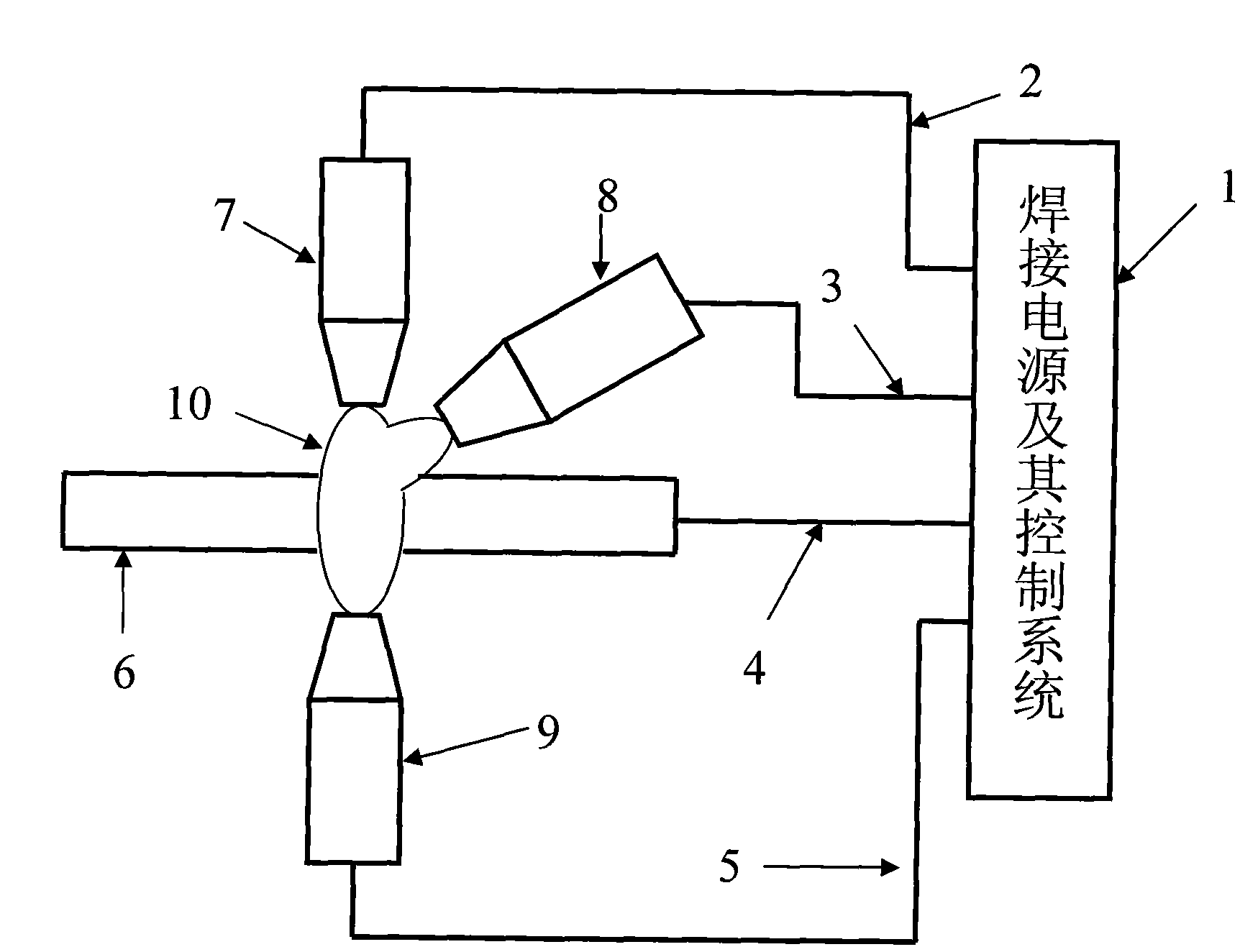

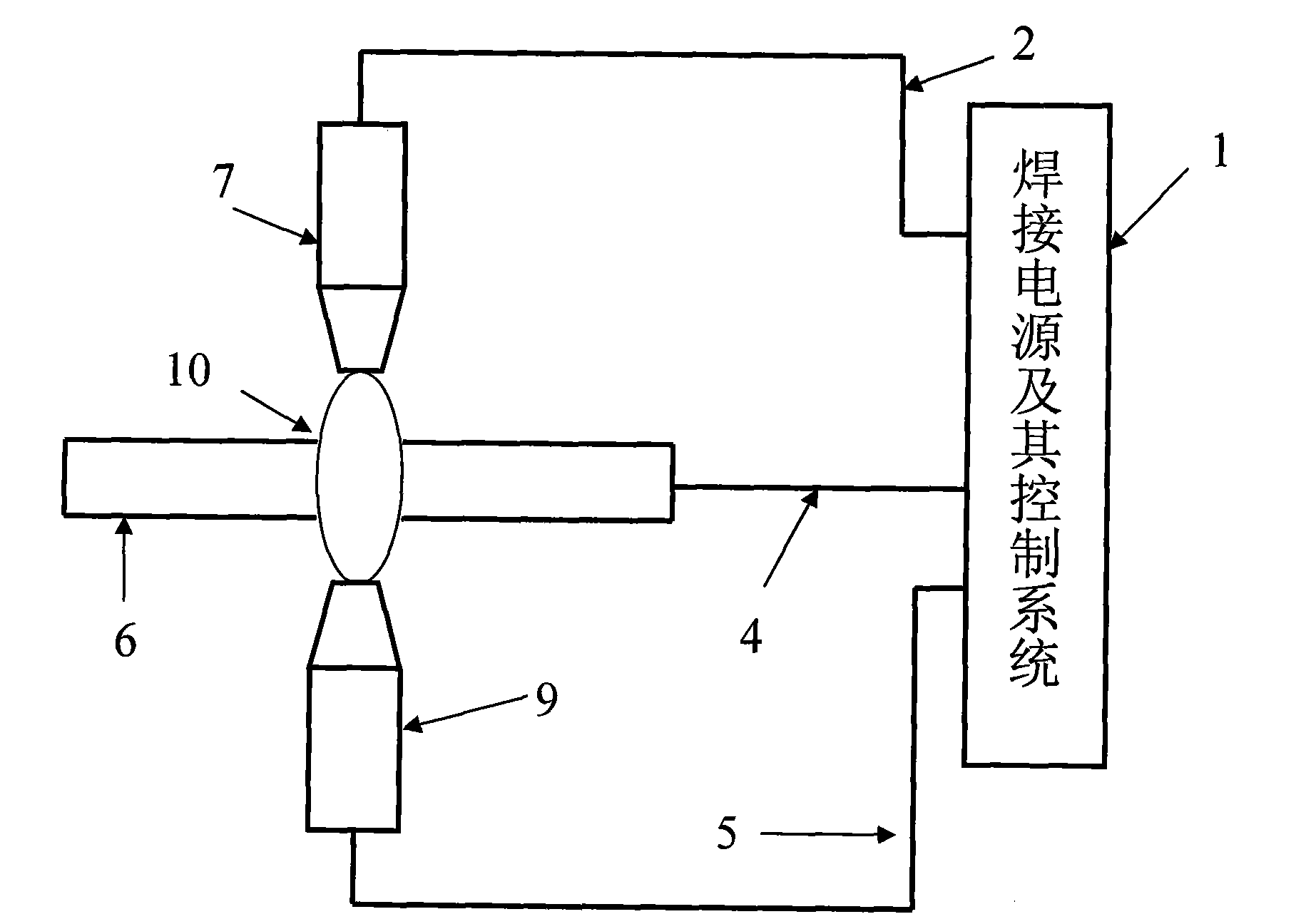

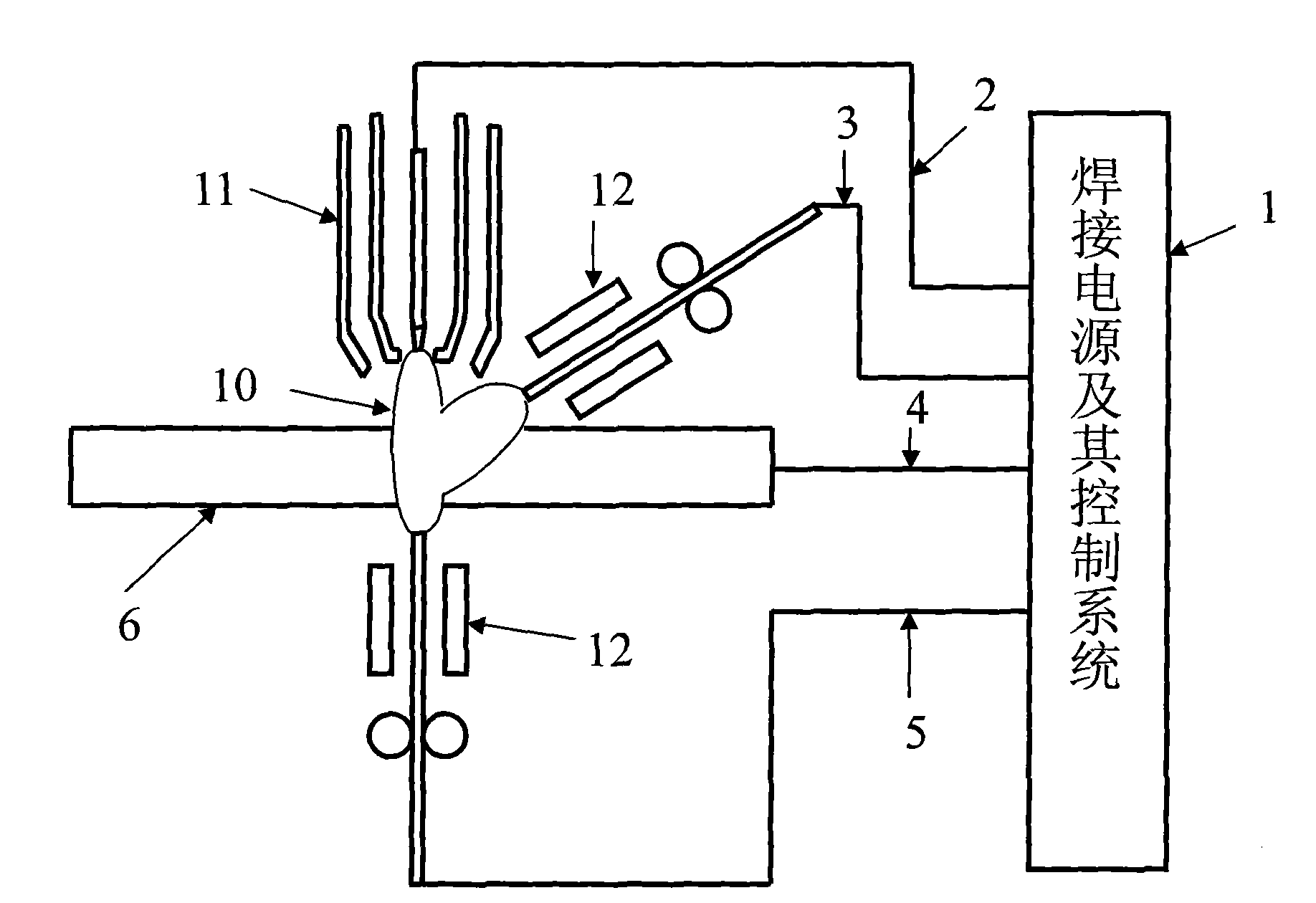

[0031] Embodiments of the present invention will be specifically described below with reference to the drawings. The workpieces to be welded in the accompanying drawings all take butt vertical welding as an example, but this is not restrictive, but only illustrative. In the accompanying drawings, only the connection mode of the welding method related to the electric circuit is illustrated, and the necessary gas circuit and water circuit connection methods of the welding torch all use conventional connection methods, so no further description is given.

[0032] Combine below figure 1 The steps of this welding method are described in detail:

[0033] (1) Prepare the workpiece to be welded;

[0034] Since the welding method uses a penetrating arc for welding, the welding torch does not need to extend into the gap when welding the medium and thick plates, so the method has very low requirements on the gap and groove of the workpiece to be welded.

[0035] (2) Place the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com