System and method for controlling continuous auto-packing machine

A technology of automatic packaging machine and control system, applied in cursor tracking, continuous automatic packaging machine bag, control of slitting process, continuous automatic packaging machine control system and control field, can solve problems such as adjustment trouble and achieve convenient operation. , Reasonable design, simple control configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

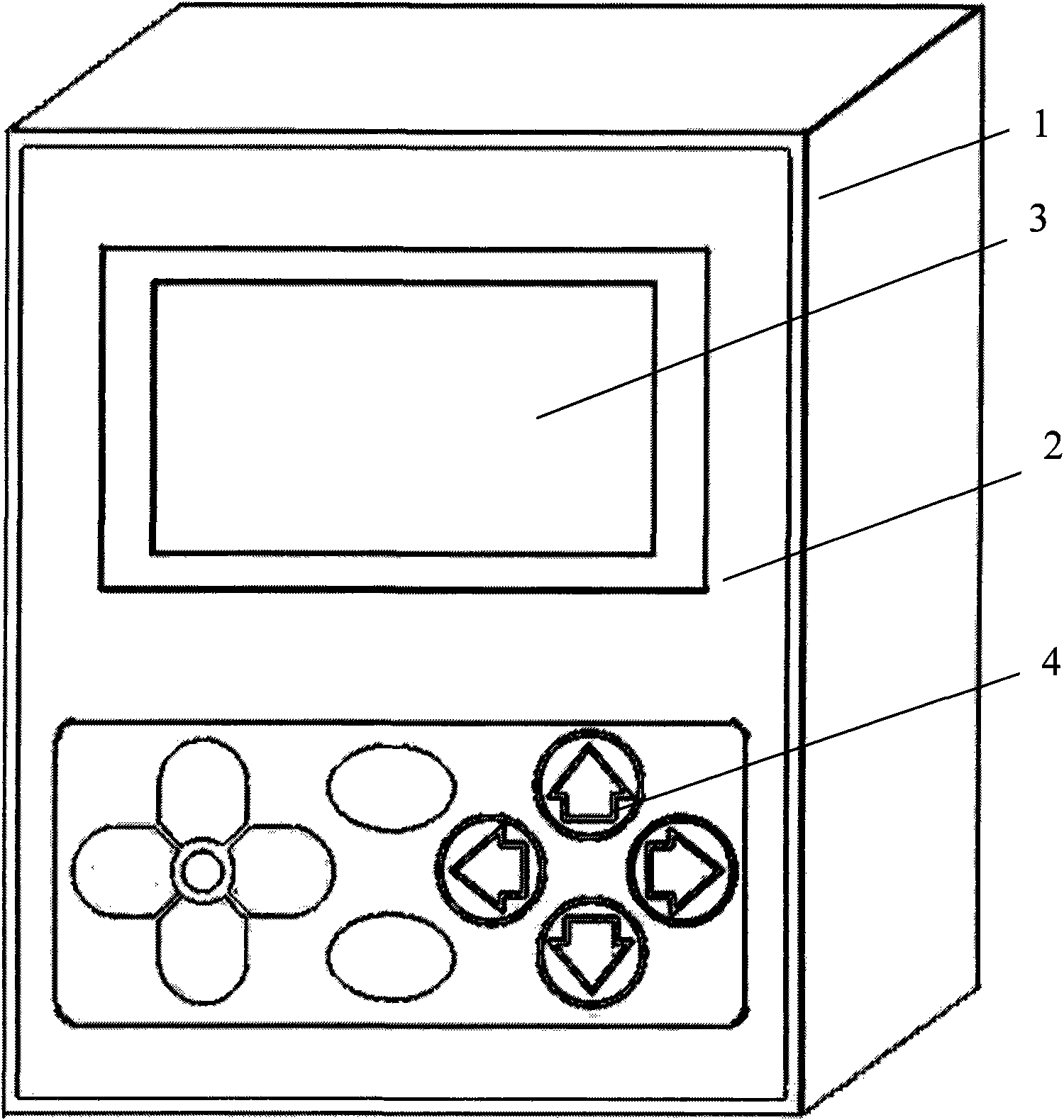

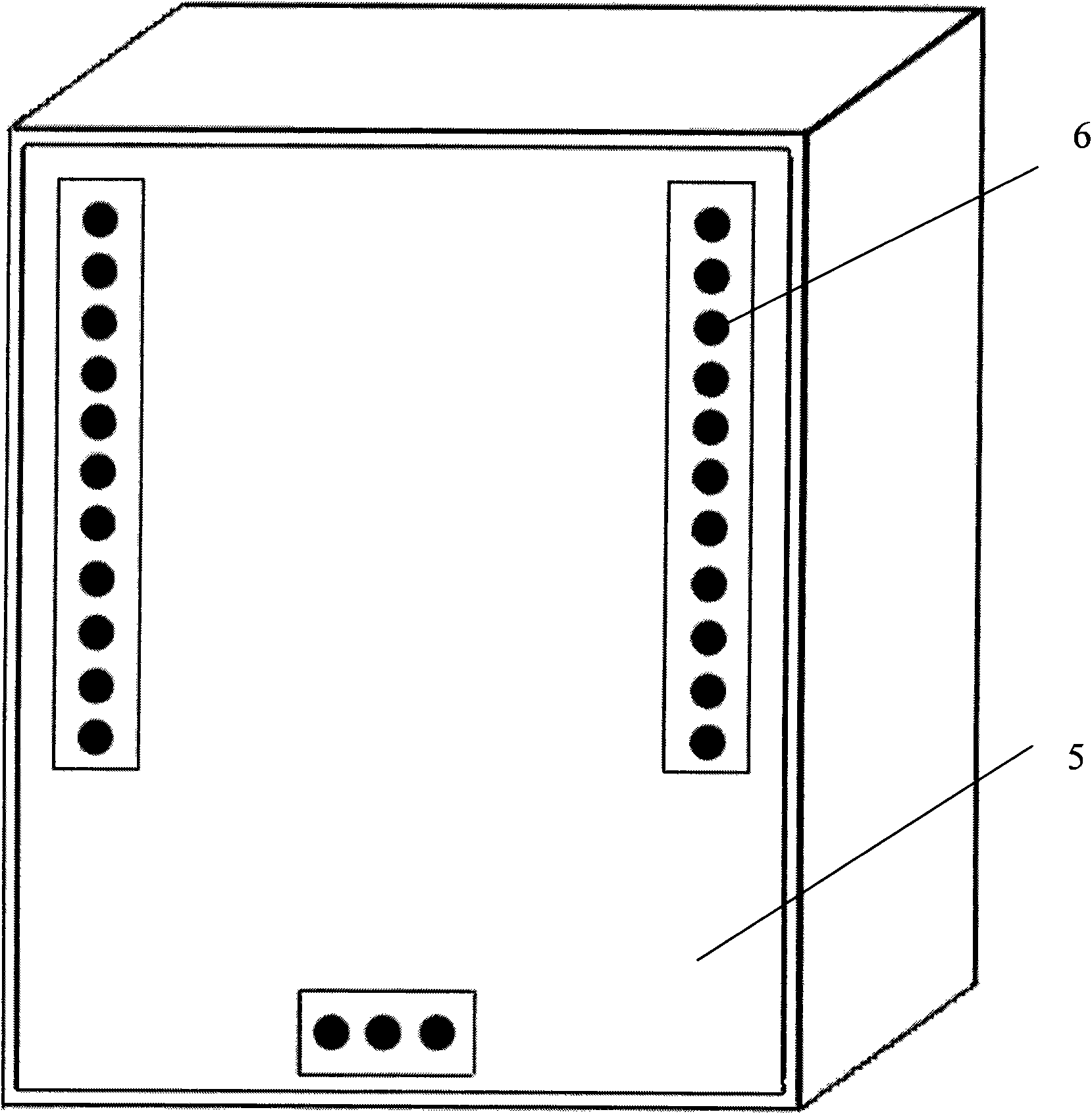

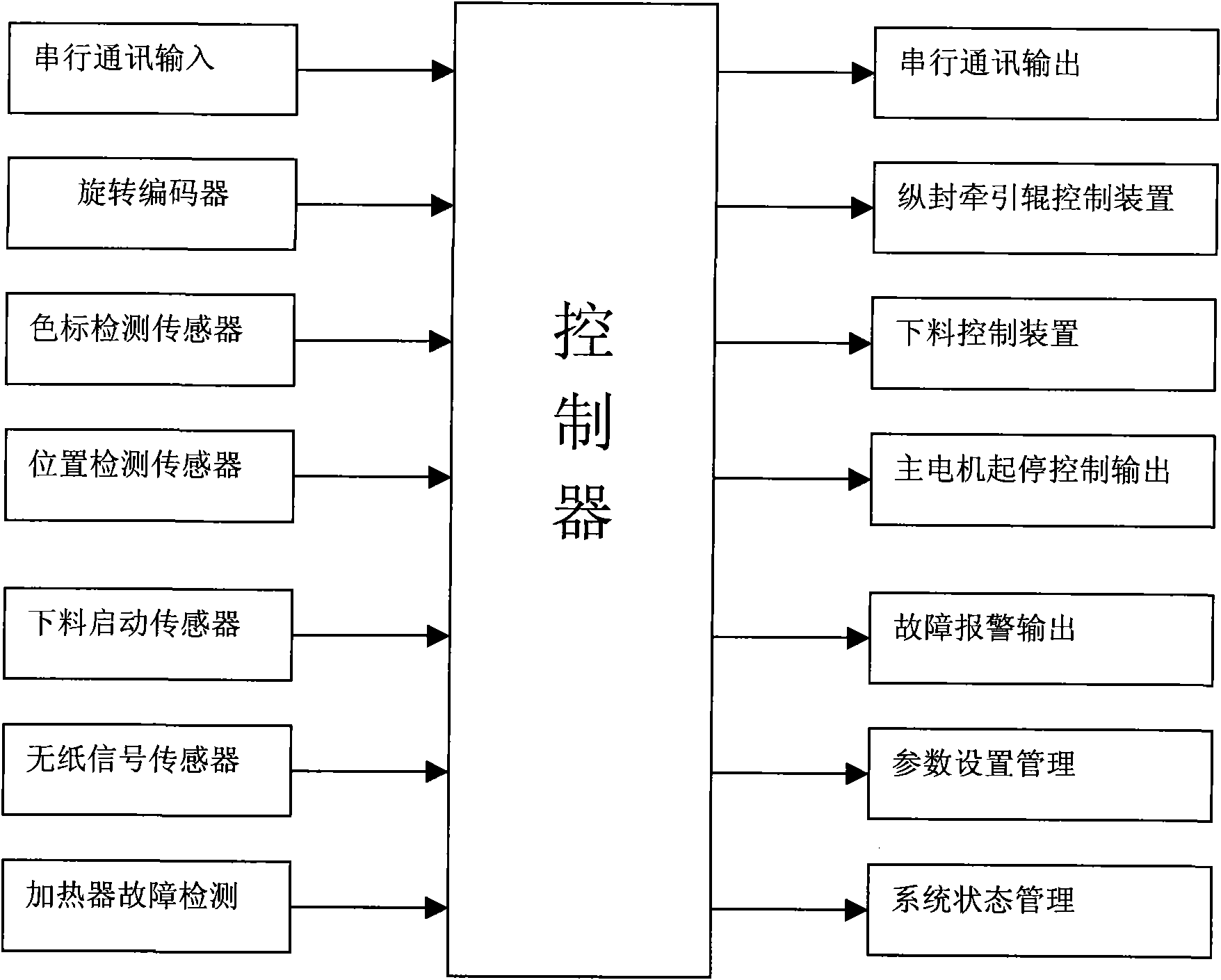

[0055] See Figure 1~5 , a continuous automatic packaging machine control system, which includes:

[0056] (1) Rotary encoder - composed of infrared photoelectric switch and rotary code disc. Through the interface with the computer, the speed measurement of the main machine of the packaging machine and the detection and control of the walking step of the longitudinal sealing traction roller are realized.

[0057] (2) Position sensor - using inductive proximity switch. Through the interface with the computer, the detection and control of the sealing position of the horizontal sealing roller of the packaging machine can be realized.

[0058] (3) Color mark sensor - use photoelectric switch. Through the interface with the computer, the detection of the color mark of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com