Quantitative filling pump with accurate quantitation and easy cleaning

An easy-to-clean and pump-filling technology, used in pumps, sausage enema machines, rotary piston pumps, etc., can solve the problems of high use and maintenance costs, low quantitative accuracy, and unsuitable cleaning, so as to save production costs, The effect of improving production efficiency and saving installation and debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure and operating principle of a precise quantitative and easy-to-clean quantitative filling pump provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

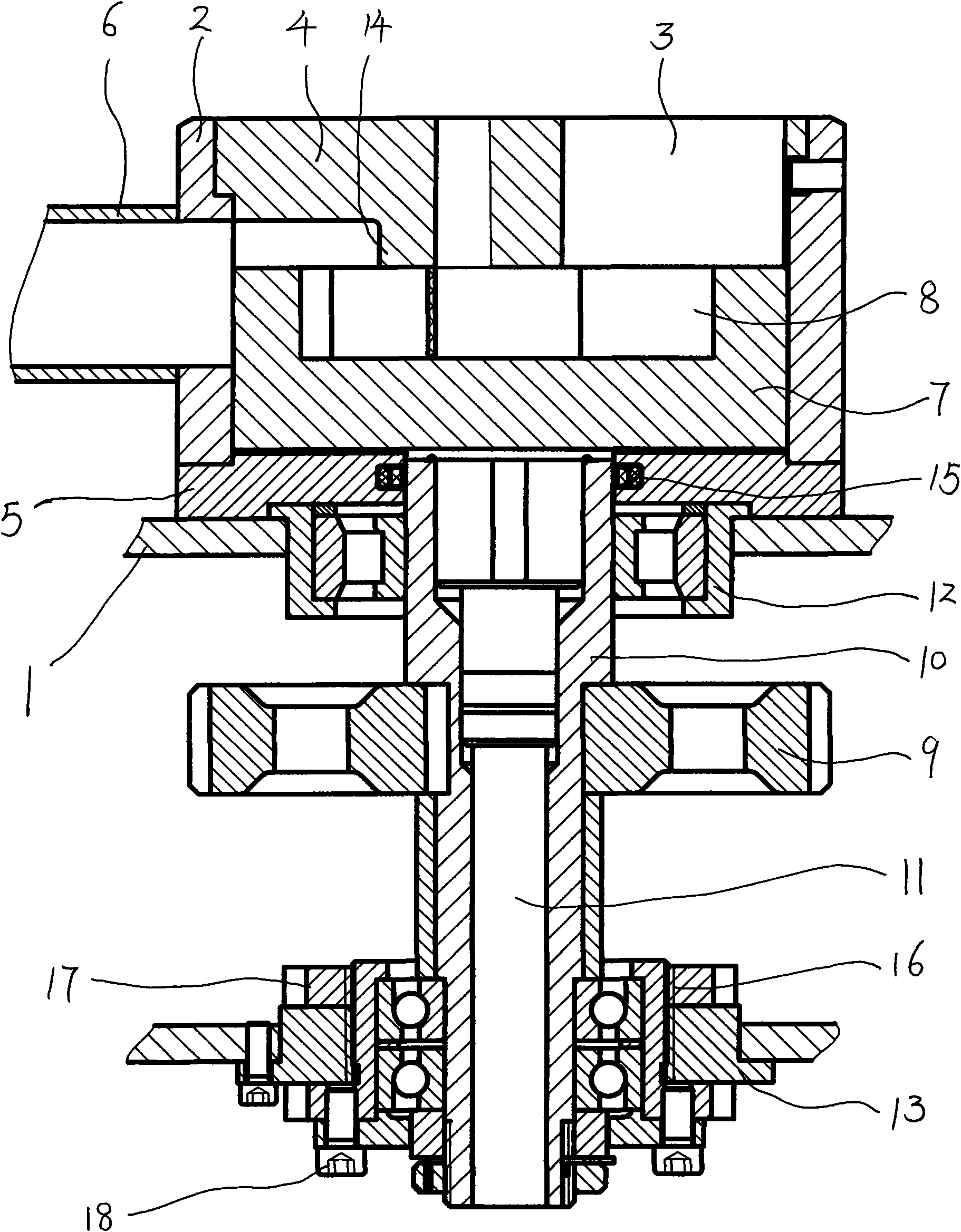

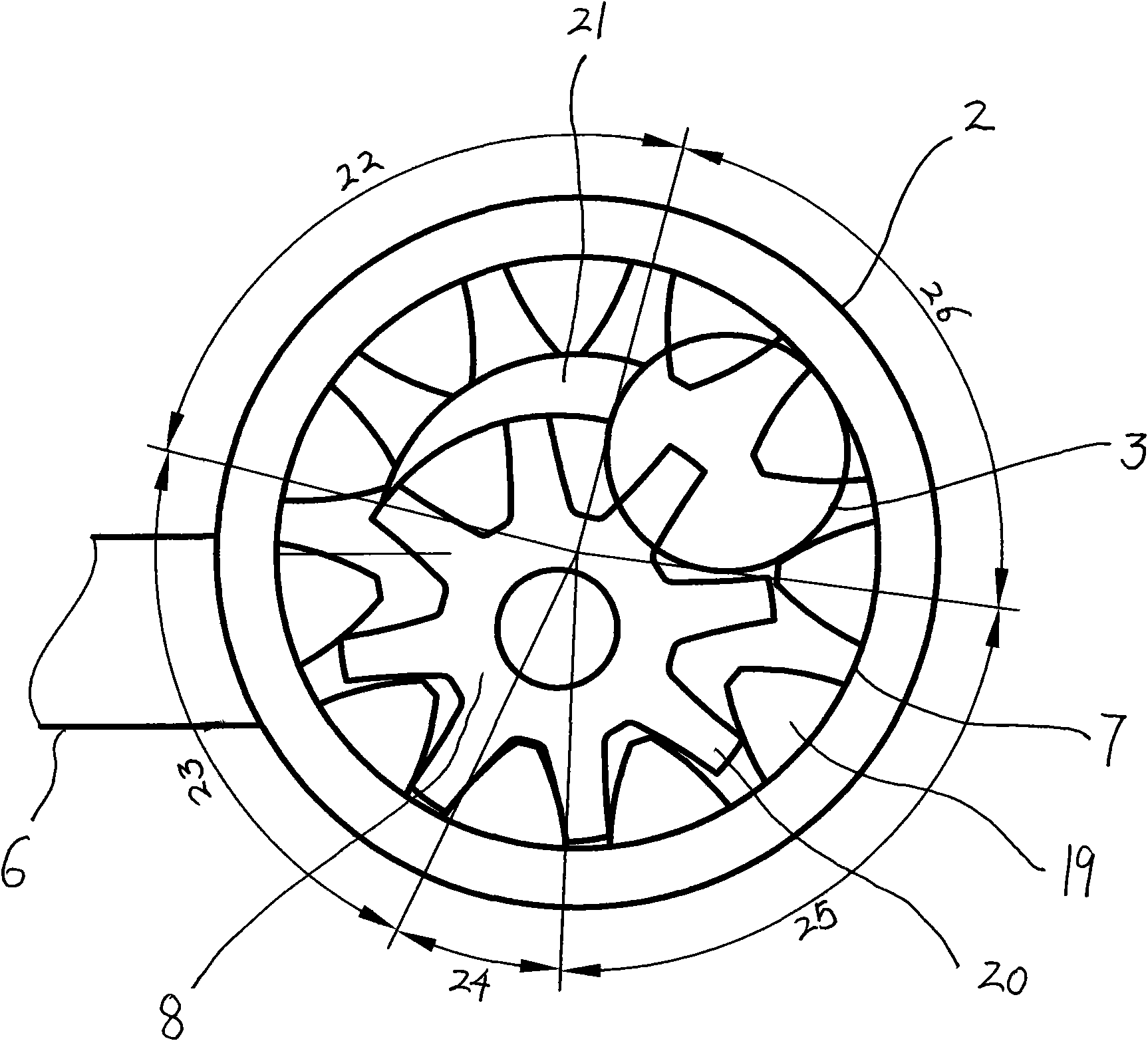

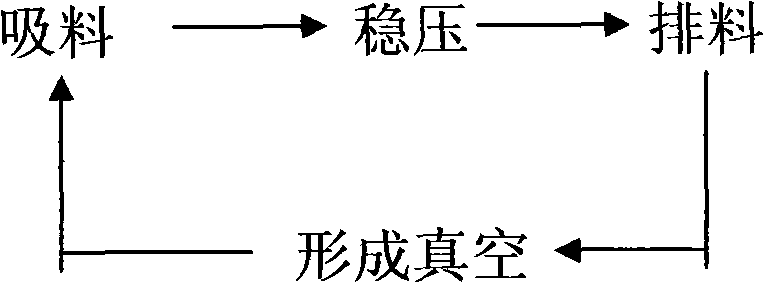

[0010] Such as figure 1 As shown, a quantitative filling pump that can be accurately quantified and easy to clean in the present invention includes a pump body 2 arranged on a casing 1, and the pump body 2 is provided with an upper pump cover 4 and a lower pump cover with a feed port 3 5. There is a discharge port 6 on the side wall of the pump body 2. An outer rotor 7 is arranged inside the pump body 2. An inner rotor 8 is eccentrically arranged inside the outer rotor 7. The bottom of the outer rotor 7 is connected to the main shaft 10 with a gear 9. The center of the main shaft 10 is the leakage port 11, the main shaft 10 is fixed with the casing 1 through the upper and lower bearing seats 12, 13, the inner rotor shaft 14 connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com