Pulley assembly of double bracing needle bearing

A technology of needle roller bearing and pulley assembly, applied in the direction of belt/chain/gear, hoisting device, element with teeth, etc., can solve the problem of slippage of the pulley assembly of double-support needle roller bearing and the service life of the belt without joints Short, short service life of the pulley assembly of double-support needle roller bearings, etc., to achieve the effect of not easy to slip, large torque, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

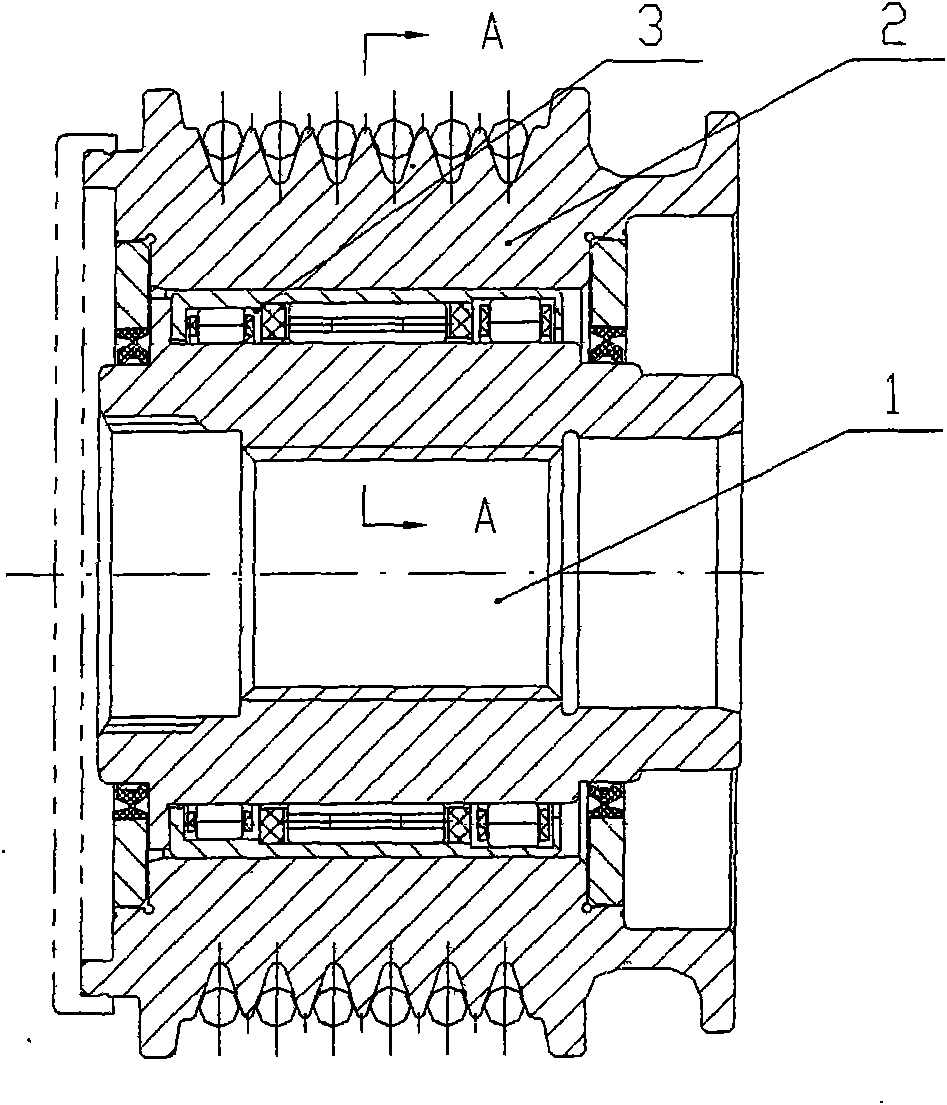

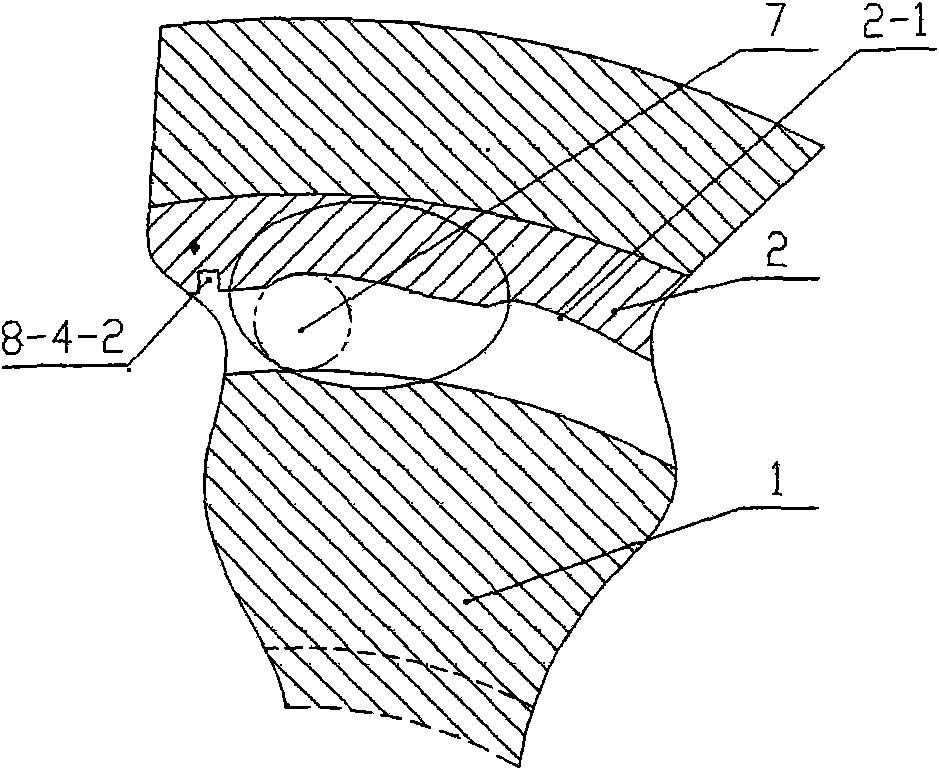

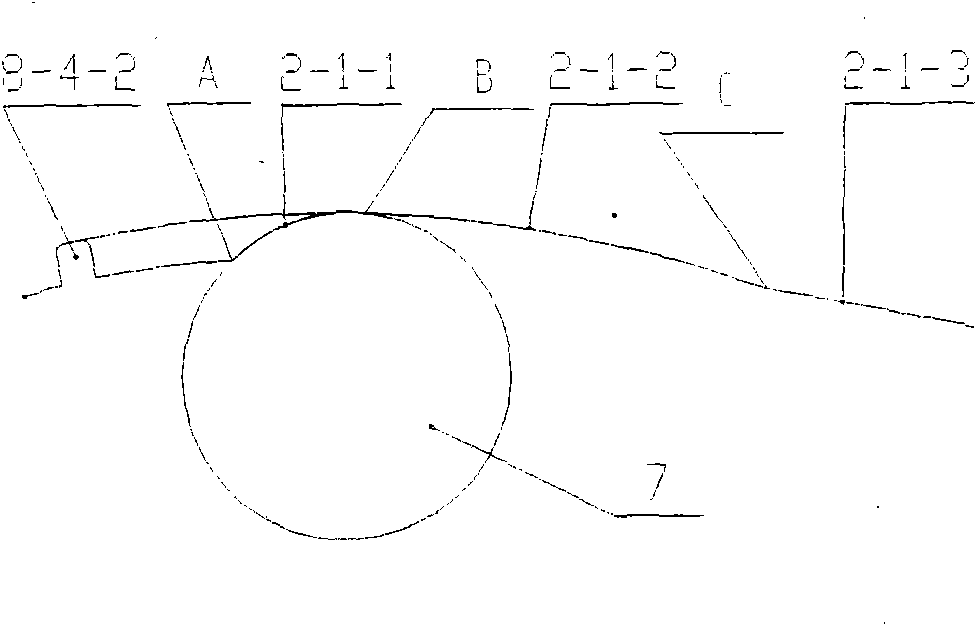

[0024] Such as Figure 1-8 The preferred embodiment of the pulley assembly of the double-supported needle roller bearing of the present invention shown has a mandrel 1 fixedly sleeved on the end of the rotating shaft of the alternator and a unidirectional shaft sleeved on the outer surface of the mandrel 1. Bearing composition; the one-way bearing has an outer ring 2, a raceway 3 is formed between the outer ring 2 and the mandrel 1, and a needle roller 7 and an arc-shaped slope for limiting the sliding area of the needle roller 7 are arranged in the raceway 3 The groove 2-1 and the cage 8 for holding the needle roller 7 are installed with a spring leaf 9 on the cage 8. The arc-shaped slope groove 2-1 is arranged on the inner wall of the outer ring 2, and the retaining The frame 8 includes first and second annular end sides 8-1 axially separated along the common axis and a beam 8-2 connecting the two annular end sides 8-1. A window hole for holding the needle roller 7 is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com