Pulp distributer provided with deslagging screen

A distributor and pulp technology, applied in gas/liquid distribution and storage, magnetic separation, solid separation, etc., can solve problems such as increasing energy consumption, and achieve the effect of energy saving, compact structure and small occupation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

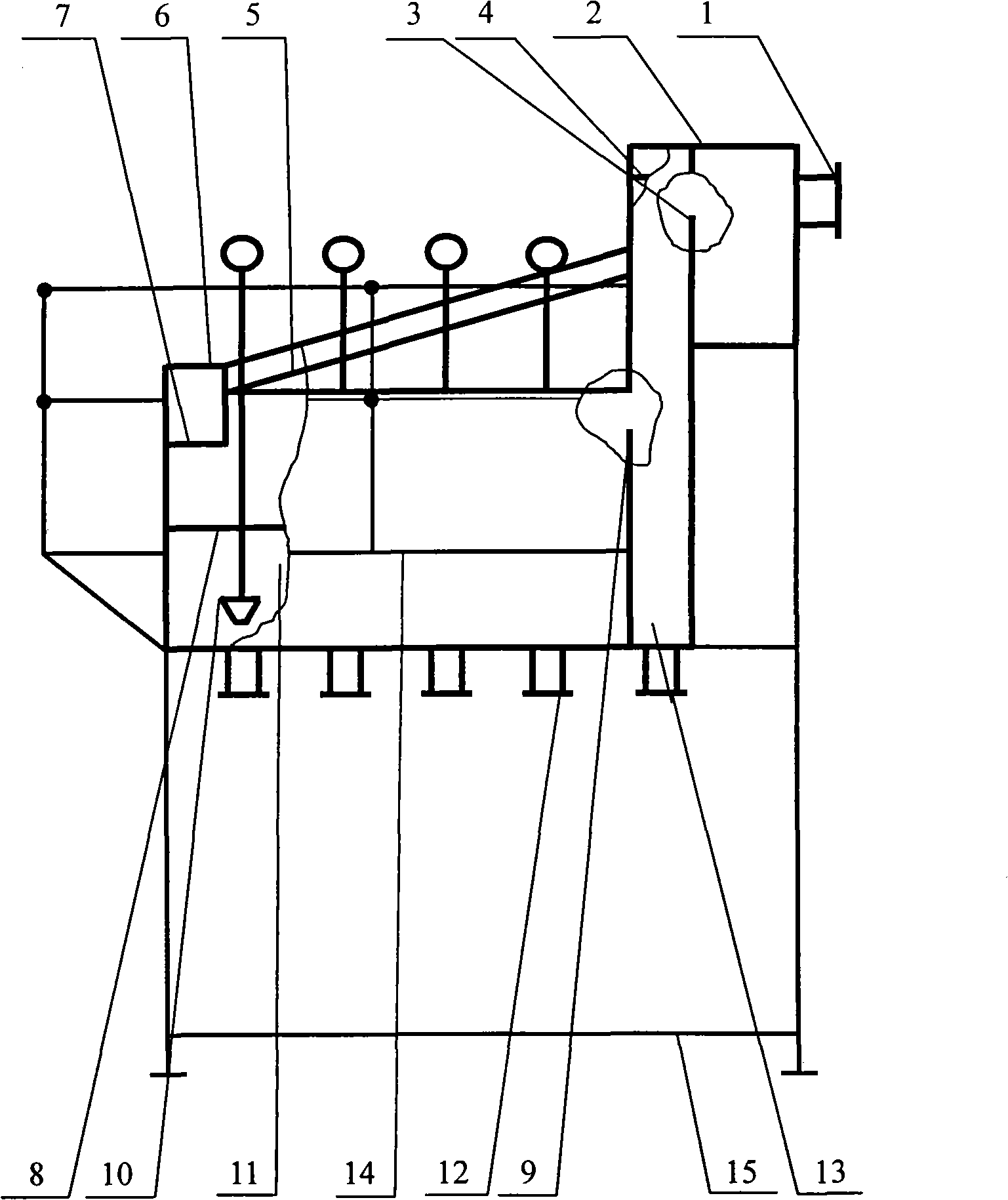

[0015] Such as figure 1 As shown, the present invention has a slurry distributor with a slag removal screen. Including bracket 15, ore feeding device, pulp distributor arranged on this bracket 15 and operating platform arranged on this bracket 15, characterized in that the ore feeding device is arranged on the end side of the pulp distributor, and the slag removal screen 5 It is installed obliquely on the upper part of the pulp distributor, one end is connected with the ore feeding device, and the other end is connected with the slag-pulp separator at the end of the pulp distributor. Overflow pipe 13.

[0016] The ore feeding device consists of an ore feeding pipe 1, a slag removal sieve feeding box 2 connected to the ore feeding pipe 1, a slag removal sieve stabilizing plate 3 arranged in the slag removal sieve feeding box 2, and a Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com