Method for automatically matching characteristic lines of close-range photogrammetry

A close-range photography and automatic matching technology, applied in the field of three-dimensional measurement, can solve the problems of limited measurement range and low measurement efficiency, and achieve the effect of avoiding loss of accuracy, avoiding the solution process, and improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

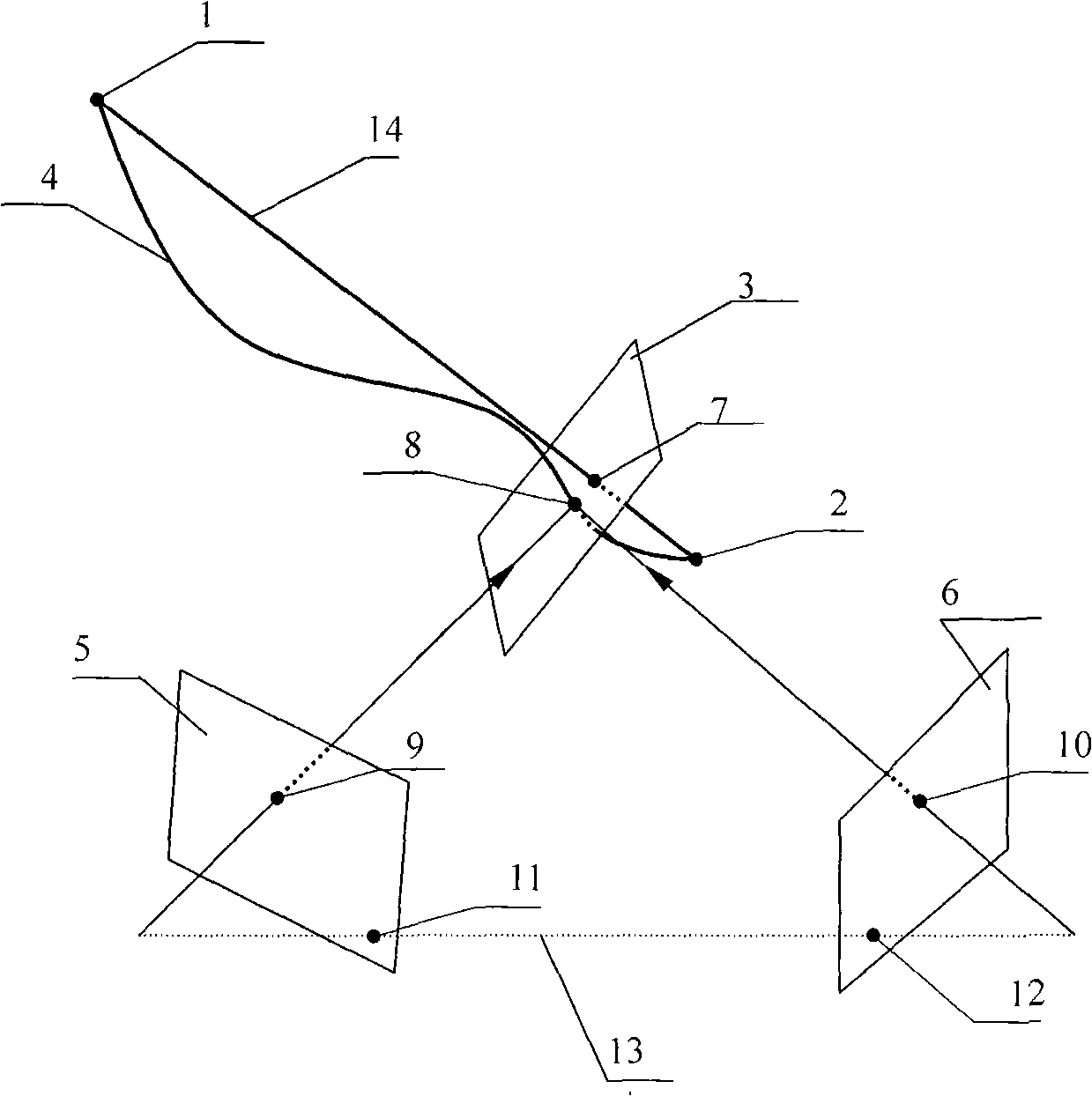

[0032] Such as figure 1 As shown, a specific embodiment of the feature line automatic matching method for close-range photogrammetry of the present invention includes the following steps:

[0033] 1. According to the principle of CAD modeling technology, draw or paste marking lines on the surface of the measured object (including its outline), so that the color brightness is obviously different from the true color of the measured object, so as to facilitate image recognition;

[0034] 2. Use coded marking points (the marking points can be identified according to the coded information of the marking points through image processing) to identify the starting and ending points of the marking line of the measured object, and automatically identify the marking line;

[0035] 3. Use one or more digital cameras to take digital images of the measured object at different angles of view; use the beam adjustment method to accurately calculate the center of the coding mark point and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com