Hexapole motor rotor punching used for injection machine

A rotor punching, six-pole motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as discomfort, and achieve the effect of eliminating electromagnetic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

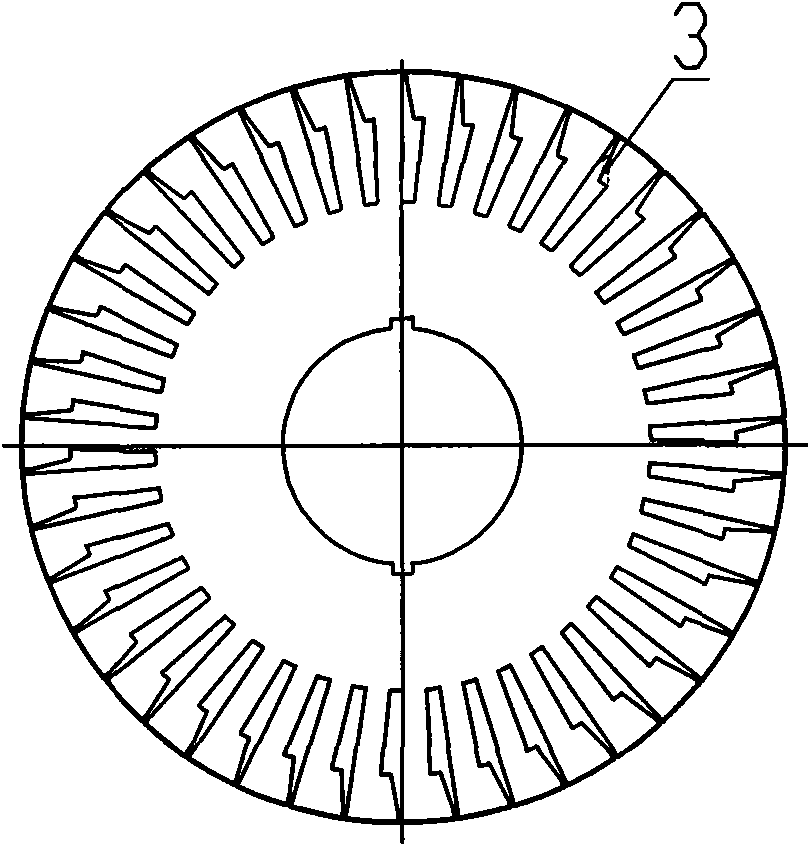

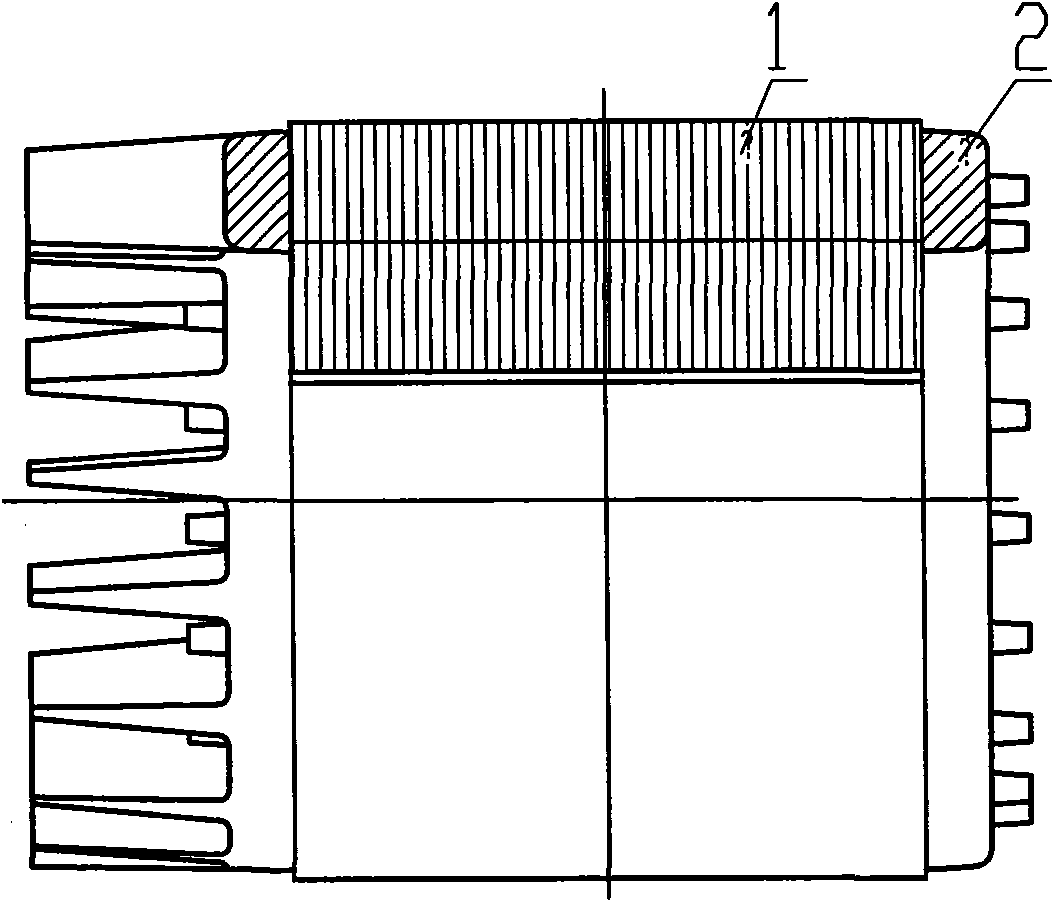

[0011] The present invention only needs to change the punching die of the rotor punching, punch out the rotor punching body 1 on the punching machine with a silicon steel sheet, and be provided with 42 grooves 3 on the rotor punching body 1 . Groove width: 3.8mm, groove depth: 35.8mm. Then die-cast a certain number of rotor stamping bodies 1 and aluminum 2 on a dedicated rotor die-casting machine to form a motor rotor stamping. The proposal of the present invention does not change the original assembly mode of the motor.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap