Linear actuator

A technology of linear actuators and actuator units, applied in the direction of piezoelectric devices/electrostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problem of immobile , Increased frictional resistance loss, large frictional resistance of the slider, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, preferred embodiments of the linear actuator of the present invention will be described with reference to the accompanying drawings.

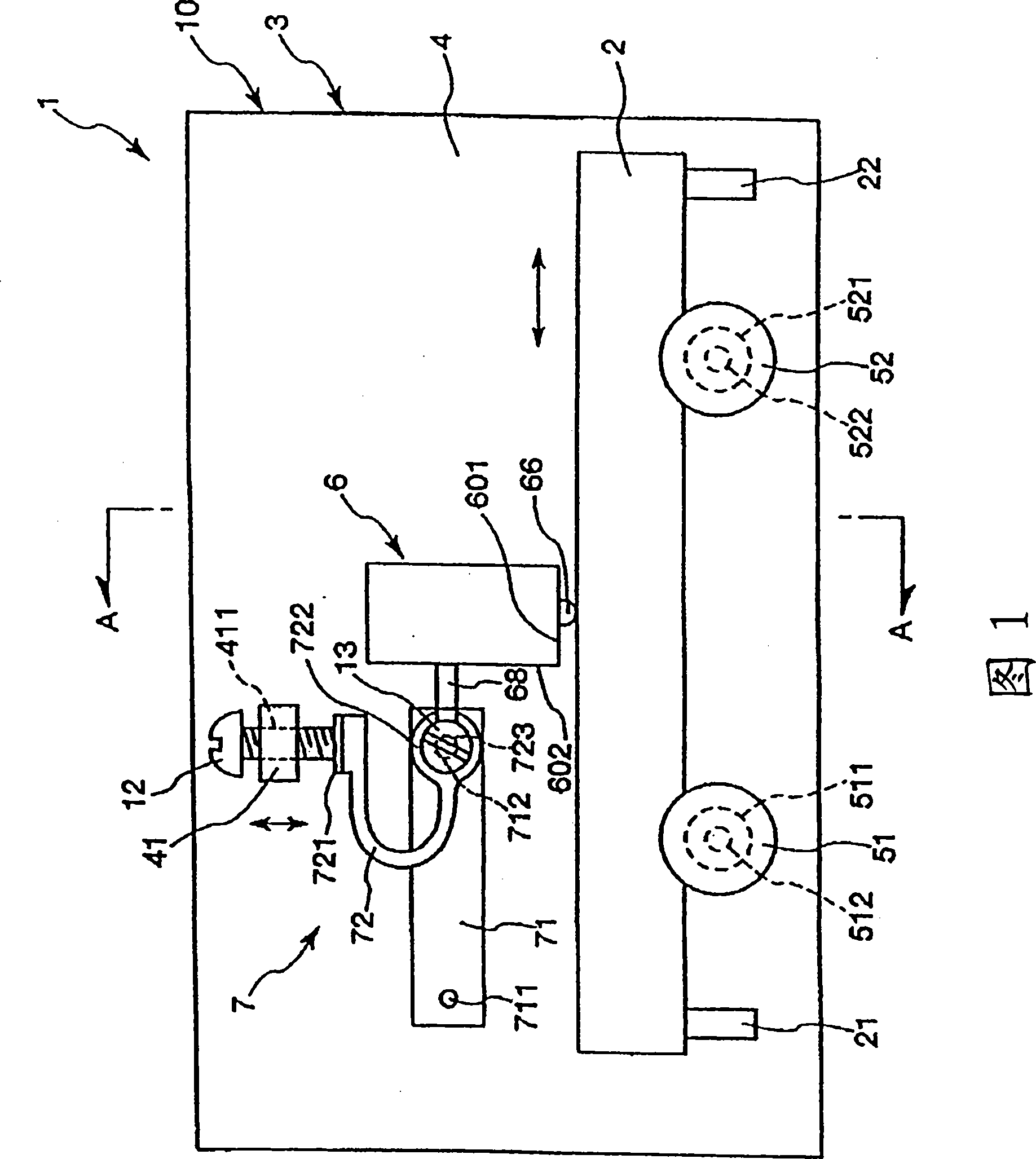

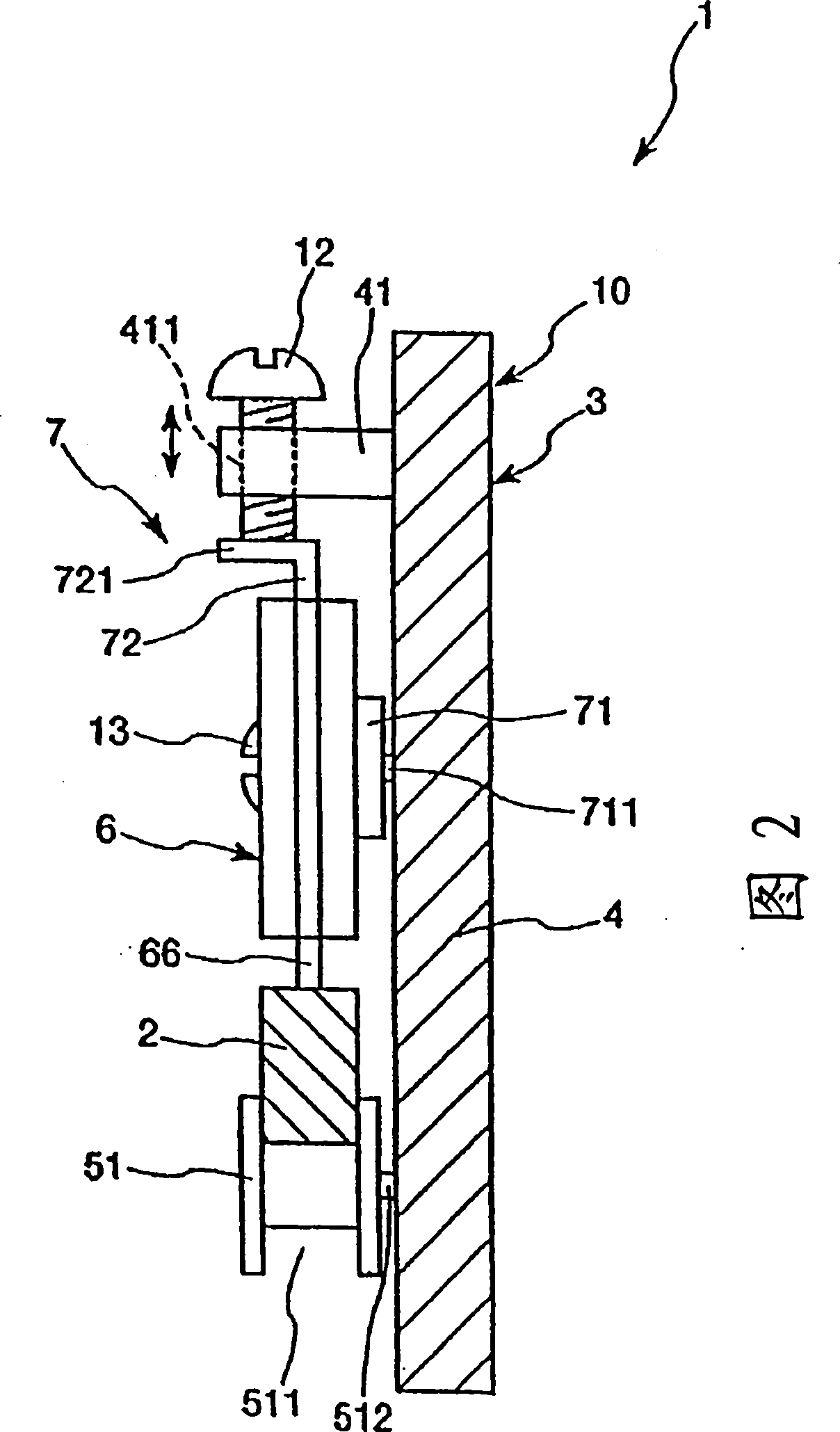

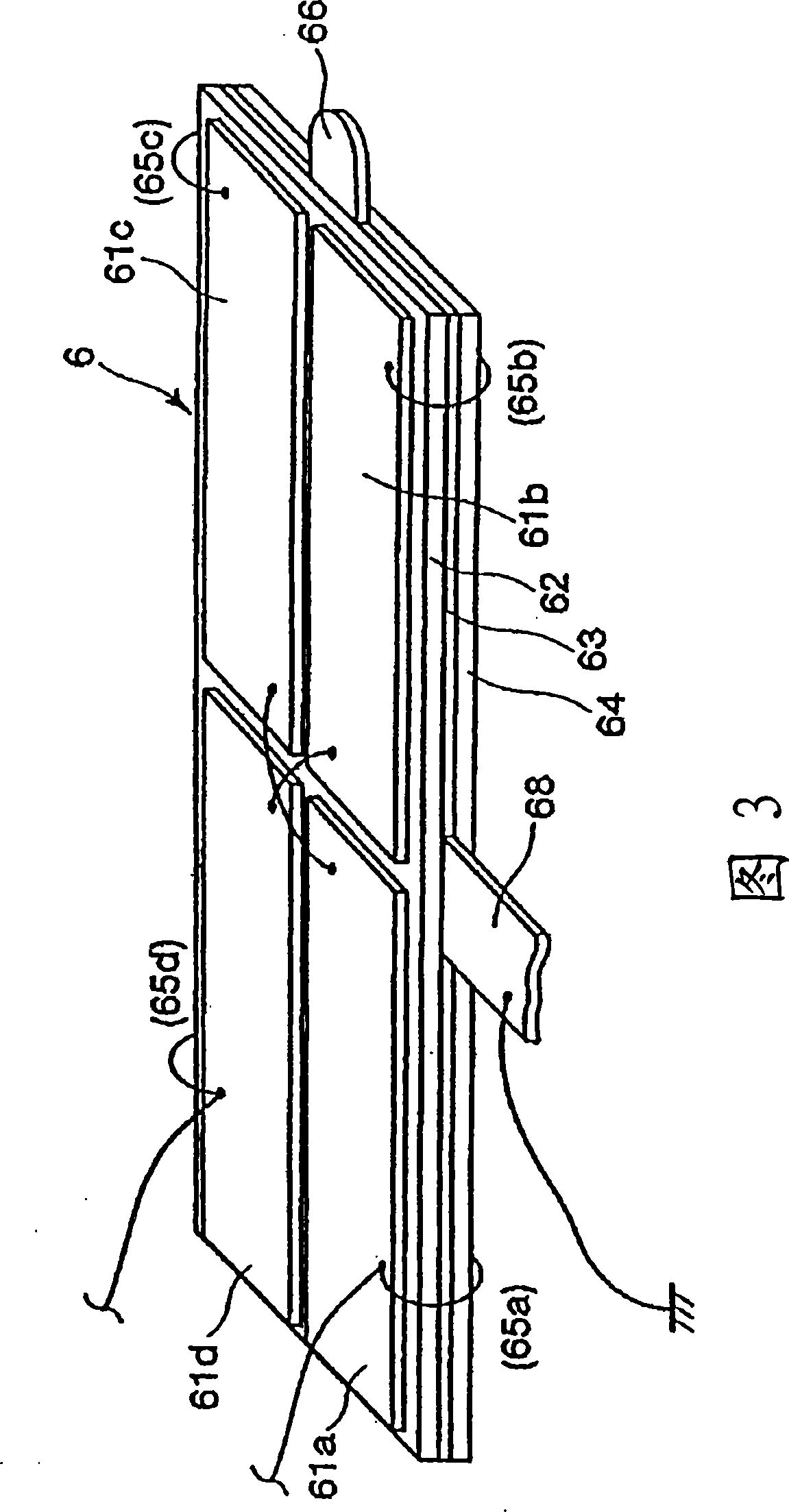

[0042] figure 1 is a plan view showing a first embodiment of the linear actuator according to the present invention. figure 2 Yes figure 1 A cross-sectional view of the shown linear actuator taken along line A-A. image 3 Yes figure 1 Perspective view of the vibrating element in the shown linear actuator. Figure 4 and Figure 5 are each shown figure 1 Plan view of the vibration state of the vibrating element in the shown linear actuator. Image 6 is showing figure 1 A block diagram of the circuit configuration of the linear actuator is shown. Here, use the following figure 1 In the description of figure 1 The upper side is called "upper", the lower side is called "lower", the right side is called "right", and the left side is called "left".

[0043] The linear actuator 1 shown in these figures is an actuator tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com